Automatic oblique arm type shaft replacing device and winding method thereof

A shaft device and automatic technology, applied in the direction of winding strips, thin material handling, transportation and packaging, etc., can solve problems such as work-related accidents and short manual operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

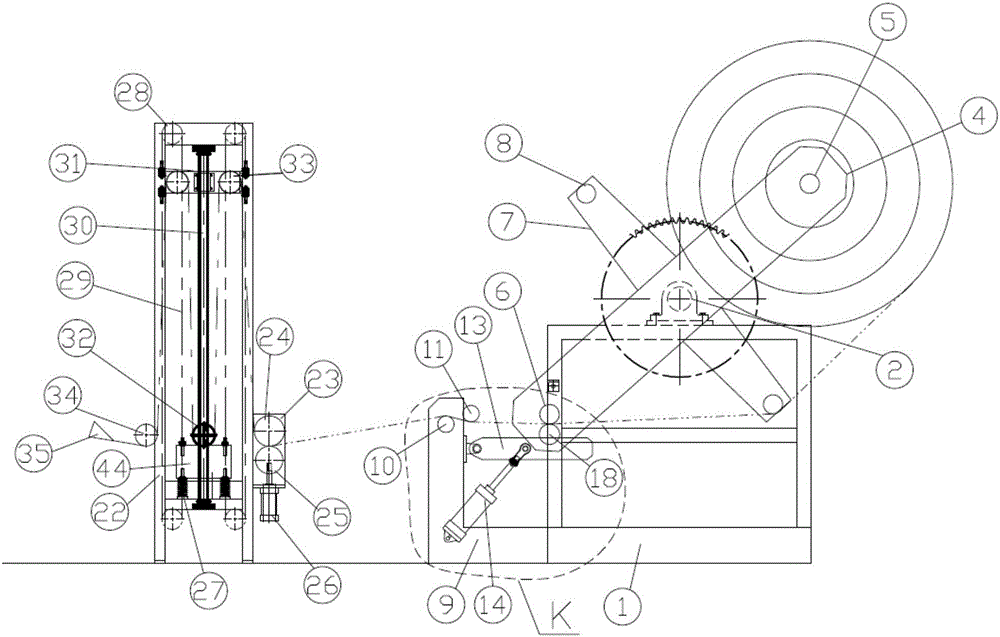

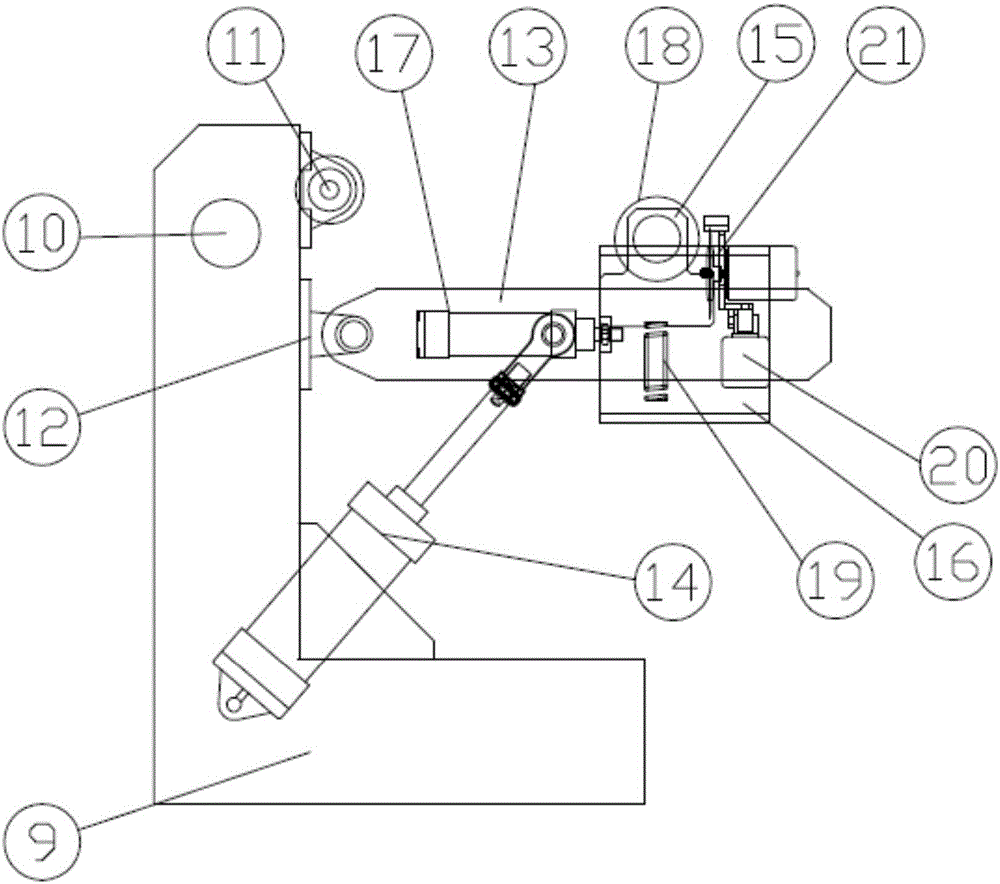

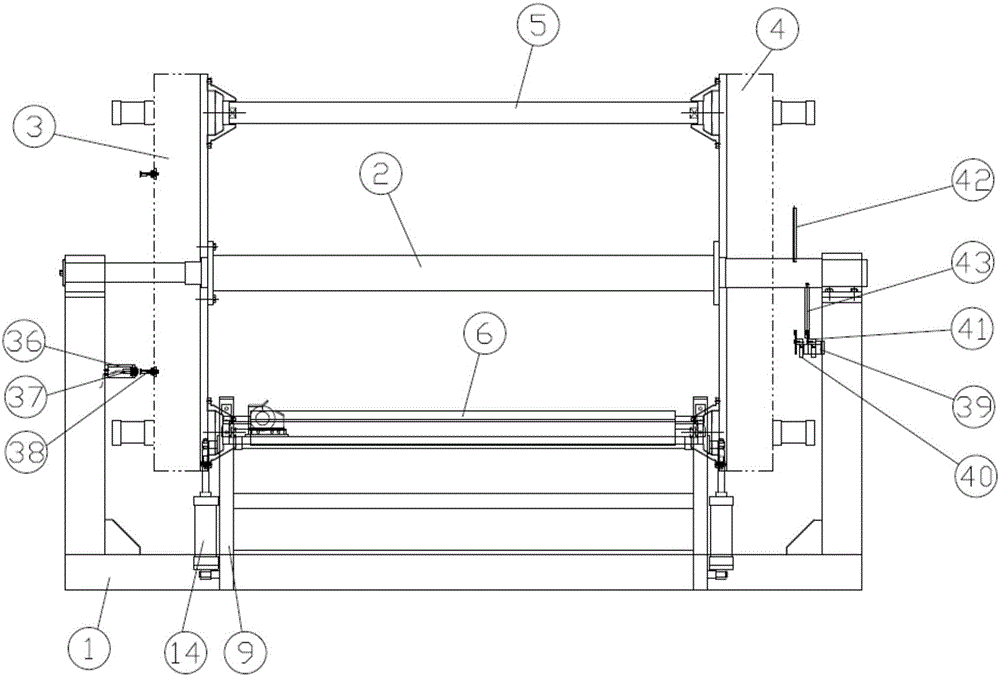

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the above technical solutions will be further described below in conjunction with the diagrams.

[0019] like Figure 4~7 Shown, the specific working steps of above-mentioned technical scheme are:

[0020] The first step is as Figure 5 As shown, start: the rotating shaft 2 starts to rotate counterclockwise, the sensing rod 38 on the swing arm 3 is facing the proximity switch 37, the B-axis limit rod 43 touches the B-axis take-up tube limit switch 41, and then the rotating shaft 2 Stop rotating, and the pressing rubber wheel 25 on the pressing slide 23 moves upward to cooperate with the pressing roller 24 to clamp the material 35. At this time, the storage rack 22 continues to feed. When the tension of the material 35 is relaxed, the counterweight 44 gradually descends, and at the same time, the traction chain 29 drives the side plate 31 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com