Screw elevator and control method thereof

A screw and elevator technology, which is applied to elevators, hoisting devices, transportation and packaging in buildings, etc., can solve problems such as safety accidents and detection device failure, and achieve the effect of improving accuracy and safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

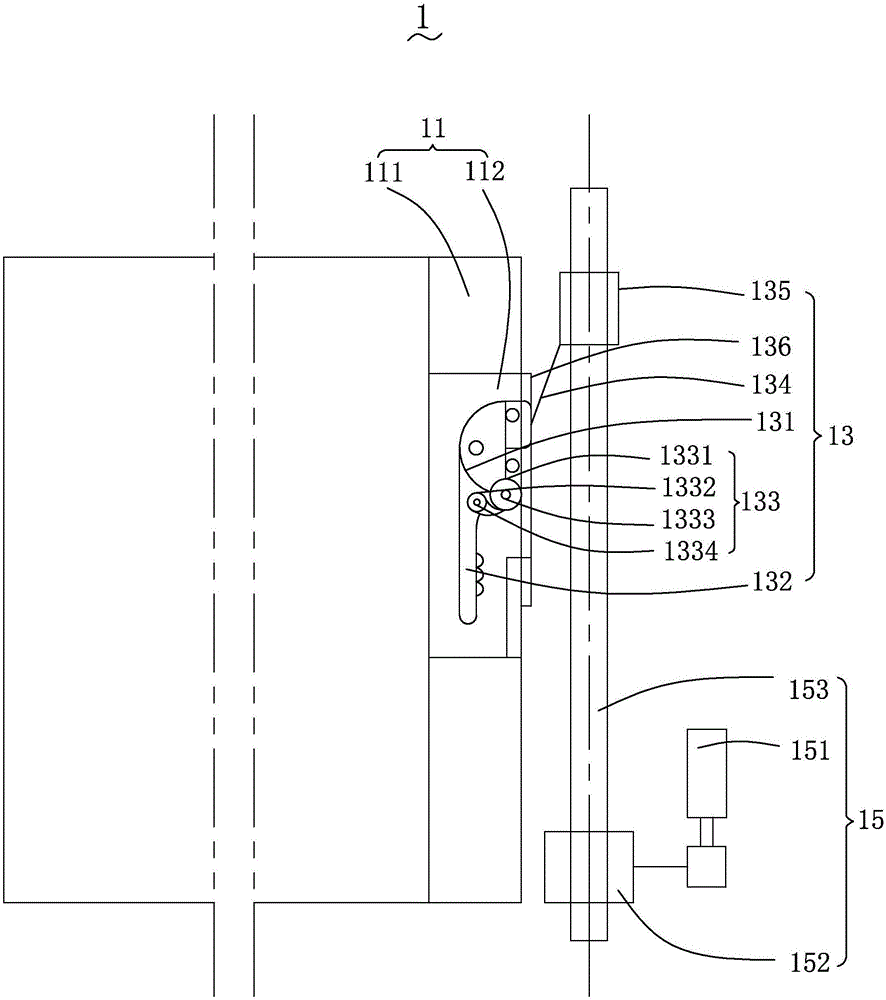

[0024] see figure 1 , is a structural schematic diagram of the screw elevator of the present invention. The screw elevator 1 includes an elevator car 11 , a hand brake device 13 and a transmission device 15 .

[0025] The motor cage 11 includes a side wall 111 and a mounting slot 112 disposed on the side wall 111 .

[0026] The handbrake device 13 includes a handbrake bracket 131 , a handbrake lever 132 , a locking mechanism 133 , a handbrake cable 134 , a brake 135 and a handbrake reinforcing plate 136 .

[0027] The handbrake bracket 131 is semicircular, and is fixedly embedded in the installation groove 112 and attached to the side wall 111 . The handbrake lever 132 is elongated, and the handbrake lever 132 is hinged to the handbrake bracket 131 . The locking mechanism 133 is located at one end of the handbrake lever 132 close to the handbrake br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com