Foundation pit support structure and construction method thereof

A foundation pit support and construction method technology, applied in the field of machinery, can solve the problems of high cost, difficulty in chiseling, and large consumption of steel and concrete, and achieve the effects of flexible operation space, improved utilization rate, and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The application will be described in further detail below in conjunction with the accompanying drawings.

[0029] The purpose of this application is to ensure the safety of foundation pit support, ensure the effect of foundation pit support, and improve construction efficiency according to the characteristics of geological conditions in coastal areas. Foundation pit support structure and construction method of stress anchor cable.

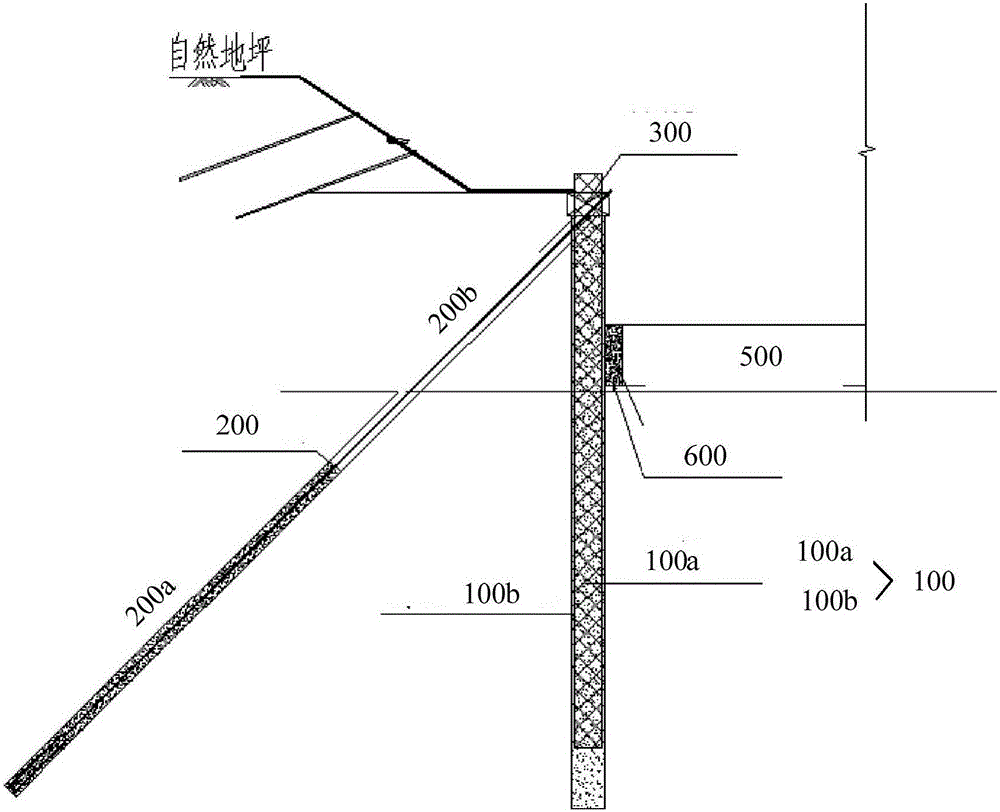

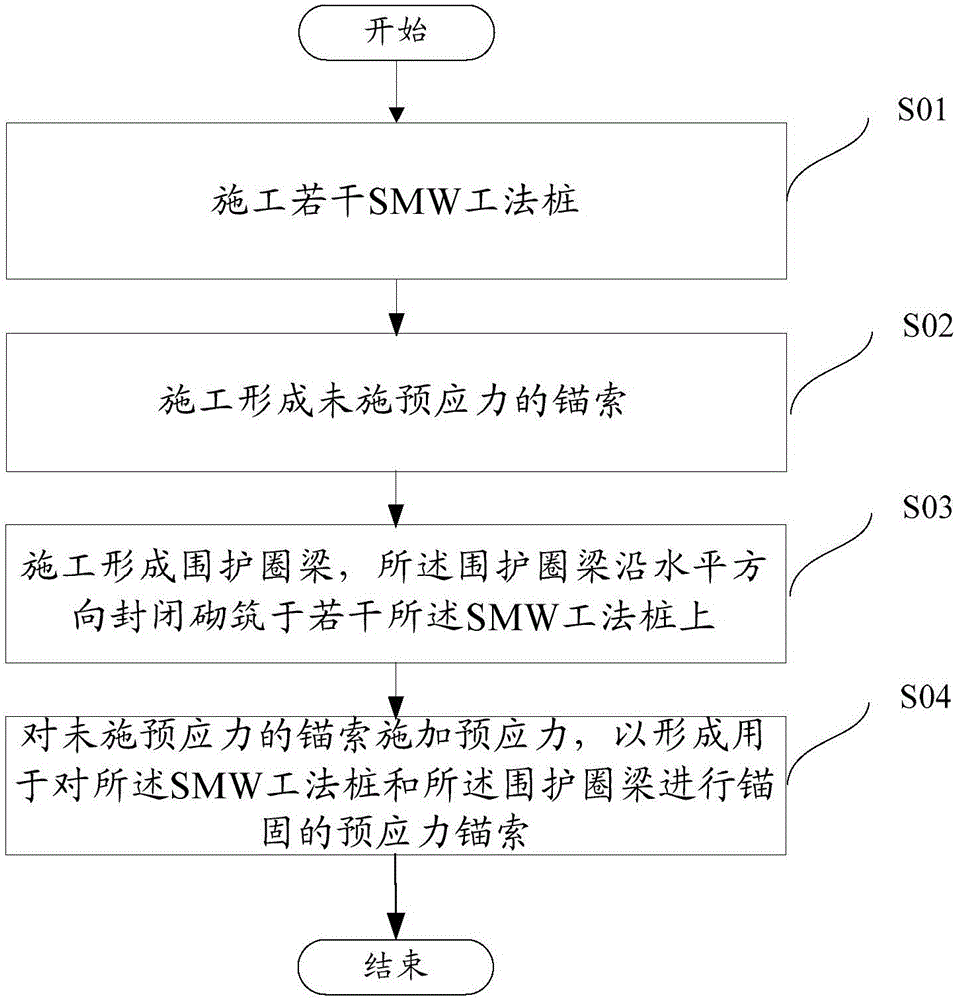

[0030] figure 1 It shows a foundation pit support structure provided according to one aspect of the present application. The foundation pit support structure is used for construction projects in coastal backfill areas. The foundation pit support structure includes at least one SMW construction method pile 100, prestressed Anchor cables 200 and retaining ring beams 300; wherein,

[0031] The retaining ring beam 300 is closed and masonry on several of the SMW engineering method piles 100 along the horizontal direction, and the prestressed an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com