Seal structure for ultralow temperature environment simulation equipment door

A technology of environment simulation and sealing structure, which is applied in the direction of sealing devices, laboratory utensils, shells or chambers, etc., can solve the problems of loss of sealing effect, surface hardening, fracture, etc., and achieve extended service life, reliable sealing, and durable sealing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

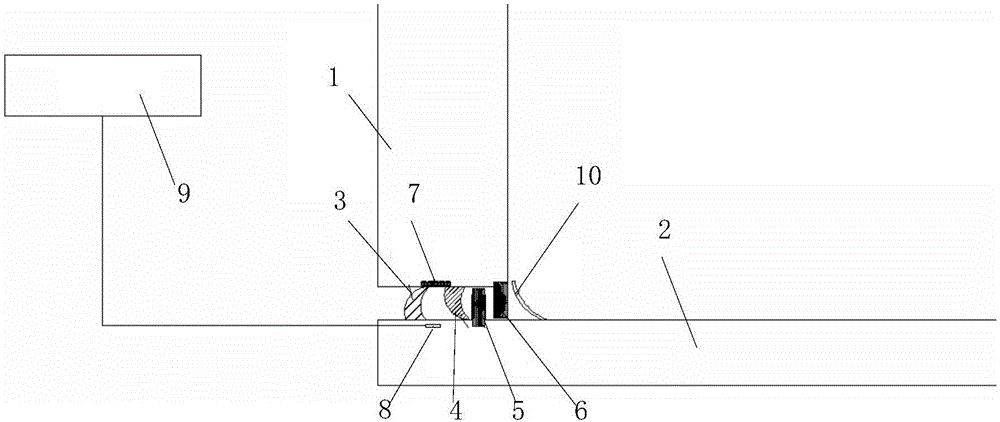

[0011] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. Such as figure 1 As shown, a door sealing structure for an ultra-low temperature environment simulation equipment includes an equipment box wall 1 and an equipment door 2. Between the equipment box wall and the equipment door, an external-use silicone sealing strip 3 and a medium-temperature silicone sealing strip are sequentially arranged from outside to inside. The sealing strip 4, the door side temperature resistance device 5 and the box wall temperature resistance device 6 are designed with a layered heat insulation mechanism at the door seal of the ultra-low temperature simulation environment test equipment, so that the cooling capacity can be effectively reduced step by step in the process of exchanging with the outside world. When the temperature weakens to the range that our special silicone sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com