Well mouth flared short joint capable of improving measuring sensitivity of return flow rate of drilling liquid and method

A flow measurement and sensitivity technology, applied in the field of wellhead bell mouth sub joints to improve the measurement sensitivity of drilling fluid return flow, can solve the problems of great influence on measurement accuracy, variation of branch pipe flow, low accuracy, etc., and achieve streamline and speed. The effect of ideal distribution, increased return speed, and improved measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

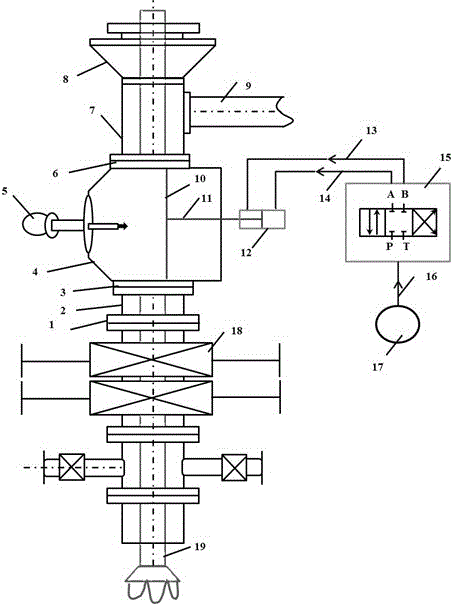

[0027] In conjunction with accompanying drawing, the present invention is further described:

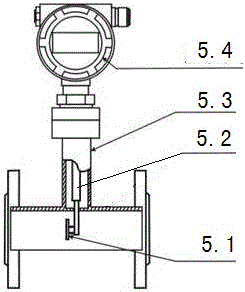

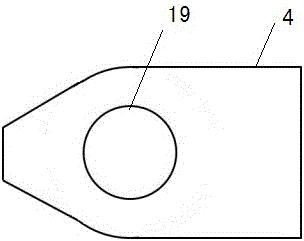

[0028] A wellhead bell-mouth pup joint that improves the measurement sensitivity of drilling fluid return flow mentioned in the present invention includes flange one (1), lower casing (2), flange two (3), and trapezoidal structure (4) , flange three (6), upper casing (7), mud umbrella (8), mud return pipe (9) and control mechanism, lower casing (2) and wellhead blowout preventer through flange one (1) (18) connection, the upper part is connected with the lower part of the trapezoidal structure (4) through the second flange (3); the upper part of the trapezoidal structure (4) is connected with the upper casing (7) through the third flange (6); the upper casing ( The upper part of 7) is movably connected with the mud umbrella (8), and the side is movably connected with the mud return pipe (9); the trapezoidal structure (4) is composed of a target flowmeter (5), a semi-cylindrical rubbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com