Ring screw smoke flue for smoke tube built-in water tube of shell type smoke tube boiler

A technology of smoke tube boilers and threaded smoke tubes, which is applied to fire tube steam boilers, fixed tubular conduit components, steam boilers, etc., can solve the problems of low heat transfer efficiency, environmental pollution, and large energy consumption, and achieve improved transmission efficiency. Thermal efficiency, small footprint, and the effect of reducing the flow cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

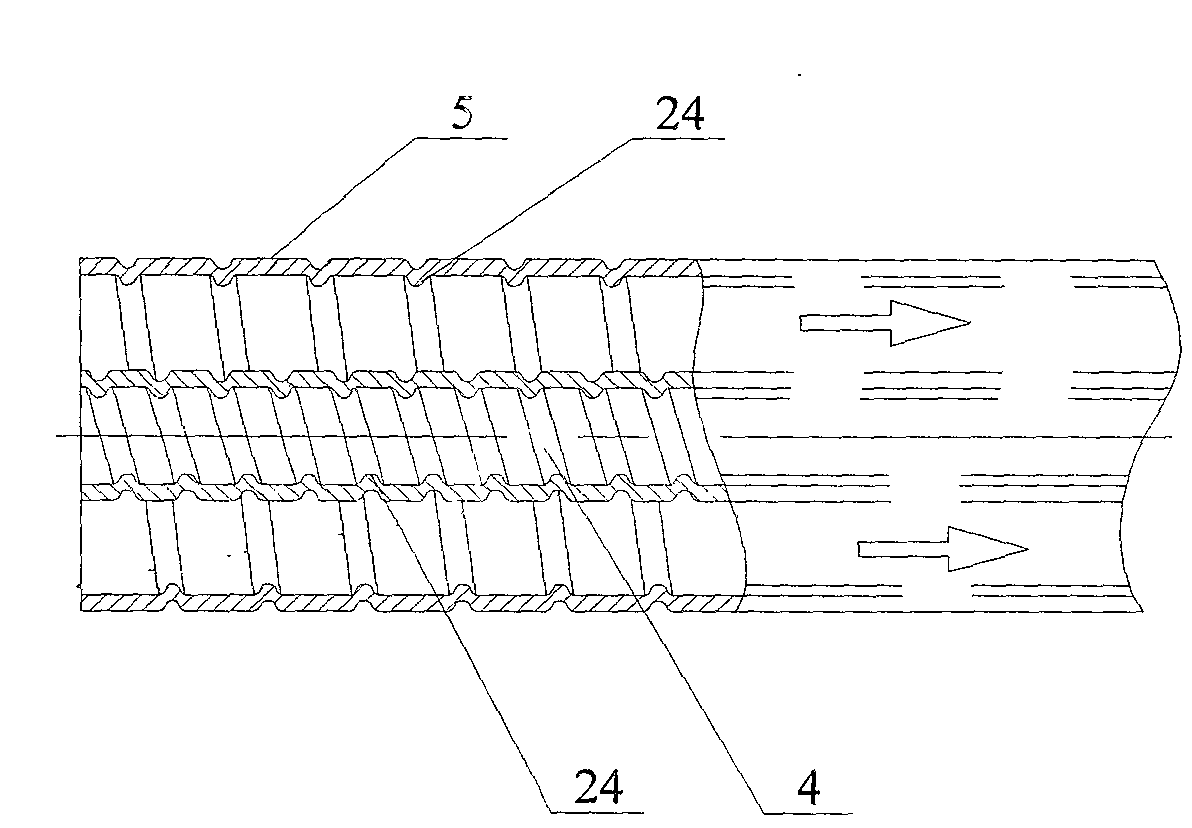

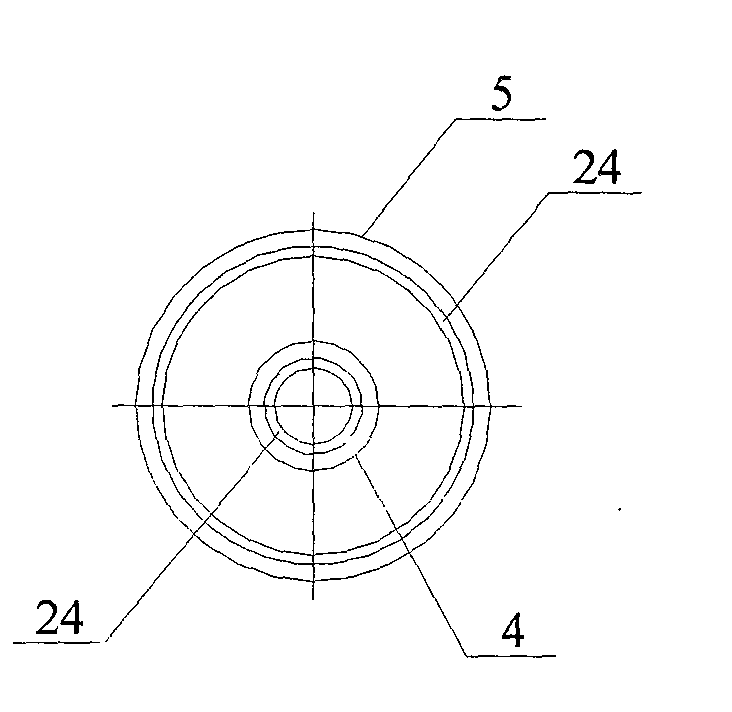

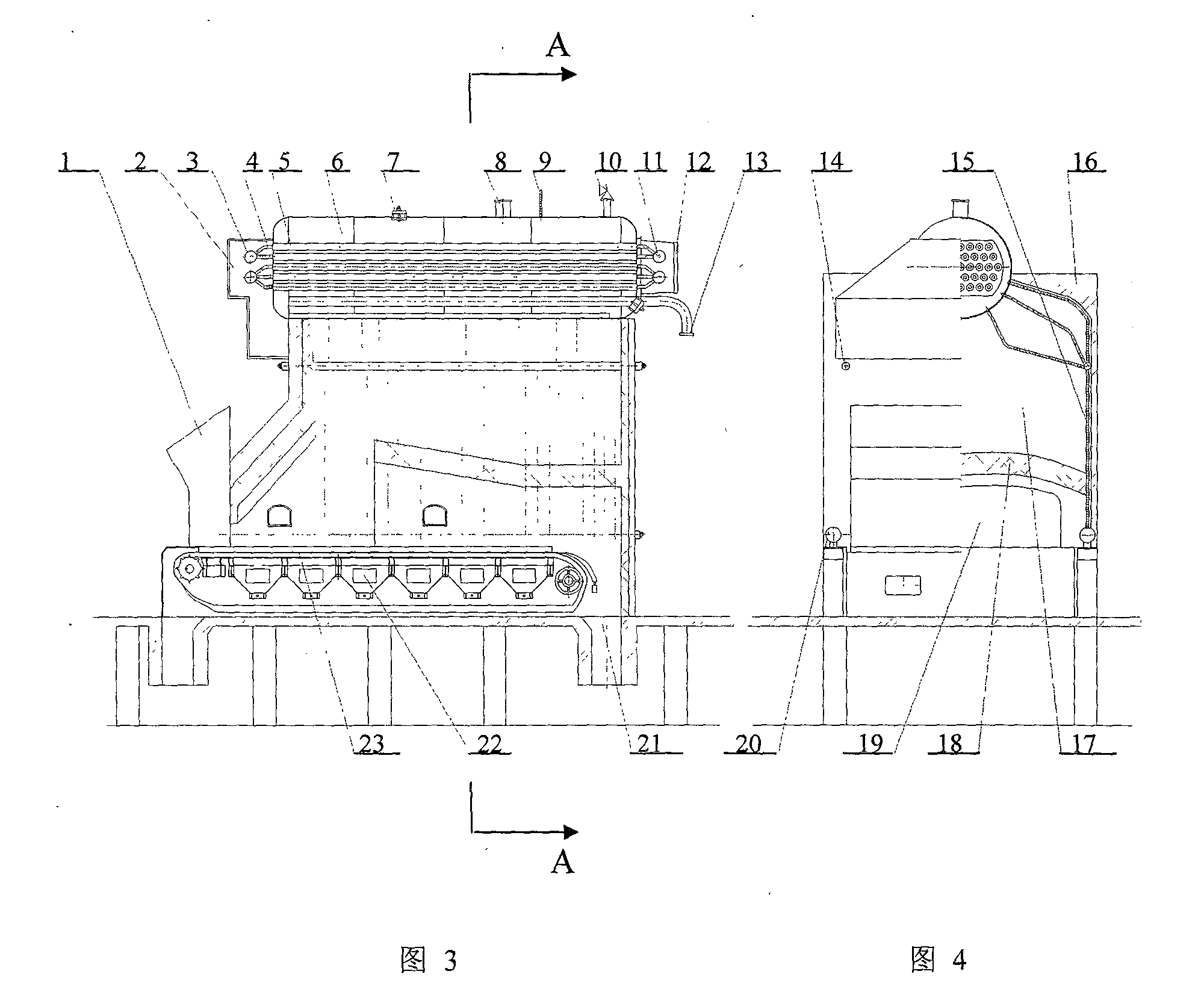

[0008] Specific Embodiment 1: This embodiment is composed of a drum 6, a threaded smoke pipe 5, and a threaded water pipe 4 axially arranged at the axis of the threaded smoke pipe 5. An annular smoke pipe is formed between the threaded smoke pipe 5 and the wall of the threaded water pipe 4. Air channel, the water channel is formed in the pipe of the threaded water pipe 4, the threaded smoke pipe 5 is arranged in the drum 6, the water inlet at the right end of the threaded water pipe 4 is connected with the right header 11, and the water outlet at the left end of the threaded water pipe 4 is connected with the left header 3 connected.

[0009] The threaded smoke pipe 5 adopts a threaded pipe whose outer diameter is Φ89 or Φ108mm, and the threaded water pipe 4 adopts a threaded pipe whose outer diameter is Φ32 or Φ38mm.

[0010] The flue gas forms a swirling flue gas channel under the action of the internal thread of the threaded smoke pipe, which significantly improves the flue...

specific Embodiment approach 2

[0011] Embodiment 2: The threaded smoke pipe 5 of this embodiment is welded on the tube plates at both ends of the drum 6 .

[0012] The working process of the boiler is as follows:

[0013] The loose coal is placed in the coal hopper 1, scattered on the fire grate, and enters in the lower furnace 19 along with the rotation of the fire grate. The coal on the grate is burned by the heat from the furnace flue gas and the heat radiated from the furnace arch, and the air entering the air chamber 22. The smoke from coal combustion flows into the upper furnace 17 from the lower furnace 19, and is cooled by the water in the furnace. The wall 15 and the part of the drum exposed in the upper furnace transfer heat and enter the flue gas chamber 2, and the flue gas swirls in the annular flue gas channel formed between the threaded smoke pipe 5 and the threaded water pipe 4 wall, so that the flue gas swirls Significantly improved, thereby strengthening the lateral scour of the pipe wall,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com