Method for preventing and treating rock burst during exploiting of working face in fault zone

A technology of rock burst and working face, which is used in surface mining, earth-moving drilling, underground mining, etc., can solve the problems of roof falling, strong concealment of rock burst, and difficulty in prevention, so as to save production costs and reduce The effect of workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

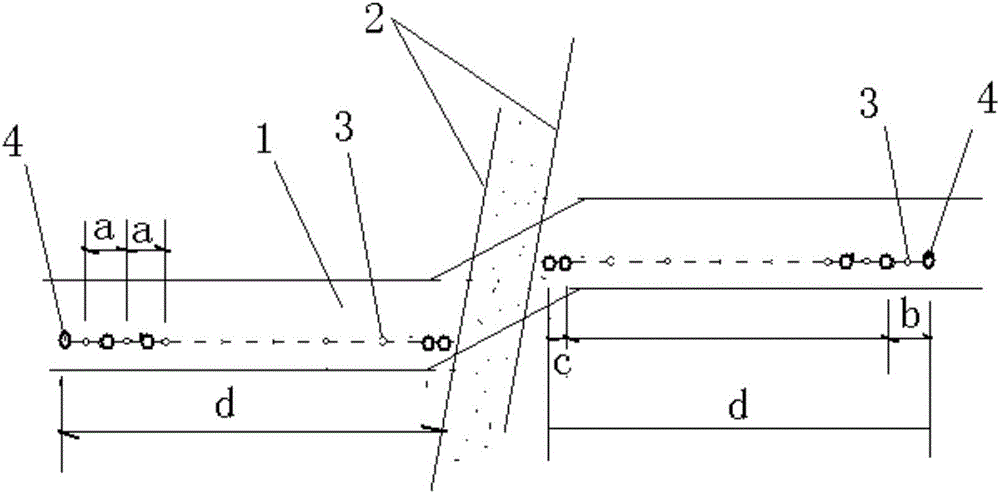

[0012] Such as figure 1 As shown, a method for preventing and controlling rock burst during mining in a working face in a fault zone, the steps are as follows:

[0013] 1. Before the construction of the roadway 1 in the mining area and before the mining of the working face, firstly, on both sides of the fault area in the roadway 1 in the mining area, within the range of d=100m from the fault plane 2, along the roadway 1 in the mining area and 1.2m away from the floor Height, construct a row of energy release oriented drilling holes into the coal seam, referred to as "energy release hole 4", the diameter of energy release hole 4 is 110-150mm, the hole depth is 8-15m, the spacing is from large to small, and the spacing starts from b=3.0m , and reduce to c=0.4-0.5m when approaching the fault plane 2; the energy release hole 4 can couple and release the energy near the fault and the energy accumulated in the coal seam along with the mining of the working face in advance.

[0014]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com