Rear connecting structure of diesel engine

A technology of diesel engine and connection structure, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of affecting the normal use of diesel engines, cumbersome operation procedures, difficult operation, etc., to achieve reasonable structure, avoid installation procedures, The effect of enhancing security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

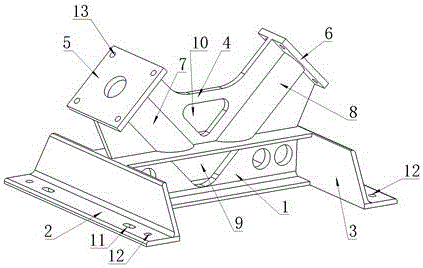

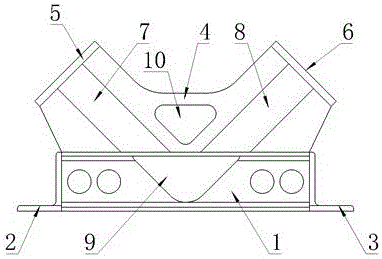

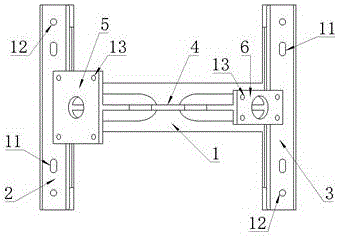

[0017] Such as Figure 1 to Figure 3 As shown, a rear connection structure of a diesel engine, while being firmly connected with the diesel engine, can also fix the whole diesel engine in the application environment more firmly and conveniently, which improves the performance of the diesel engine in application. safety. The present invention includes a main structure 1, which is the main structure of the whole part and ensures the strength of the whole part. Both sides of the main structure 1 are respectively provided with a first fixing structure 2 and a second fixing structure 3 for fixing the whole, and an engine connection structure 4 is connected above the main structure 1, and the engine connection structure 4 is closely connected with the diesel engine. The other parts are connected together so that the other parts become a whole with the diesel engine. The engine connection structure 4 is provided with a first engine connection end 5 and a second engine connection en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com