Low-temperature self-sealing connector

A self-sealing and connector technology, which is applied in the connection with fluid cut-off device, pipe/pipe joint/fitting, passing components, etc. It can solve the problems of large size, inconvenient docking operation, and inapplicable pneumatic valve opening, etc., to achieve The effect of reducing the burden of operation and facilitating docking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better illustrate the present invention, the present invention will be described in detail with a preferred embodiment and with accompanying drawings, specifically as follows:

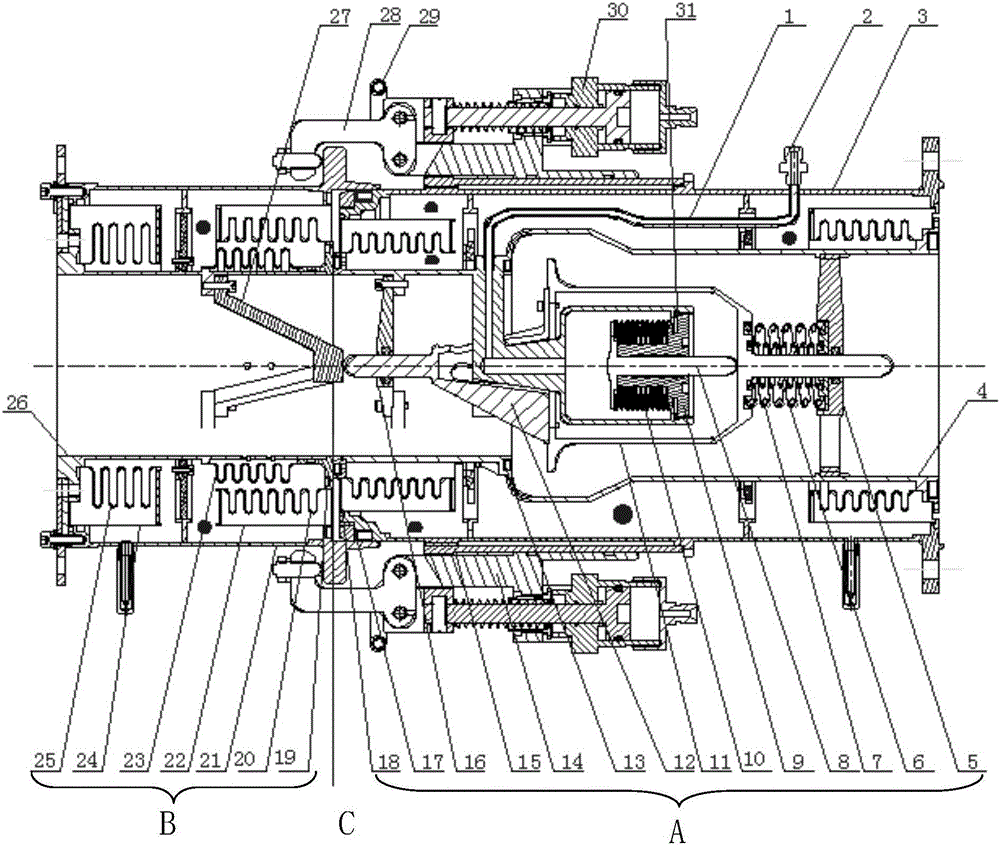

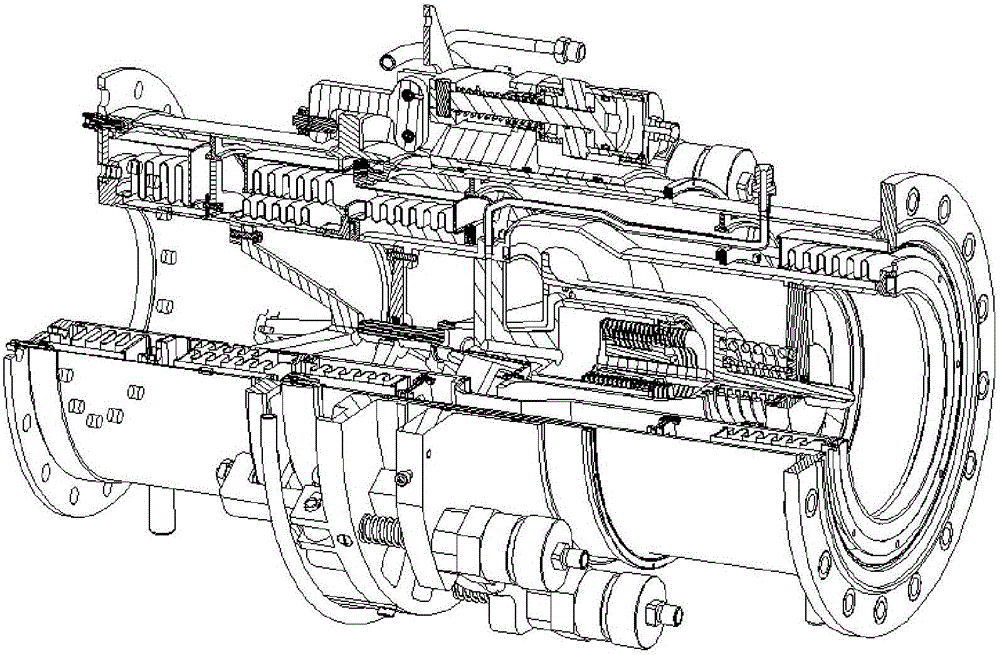

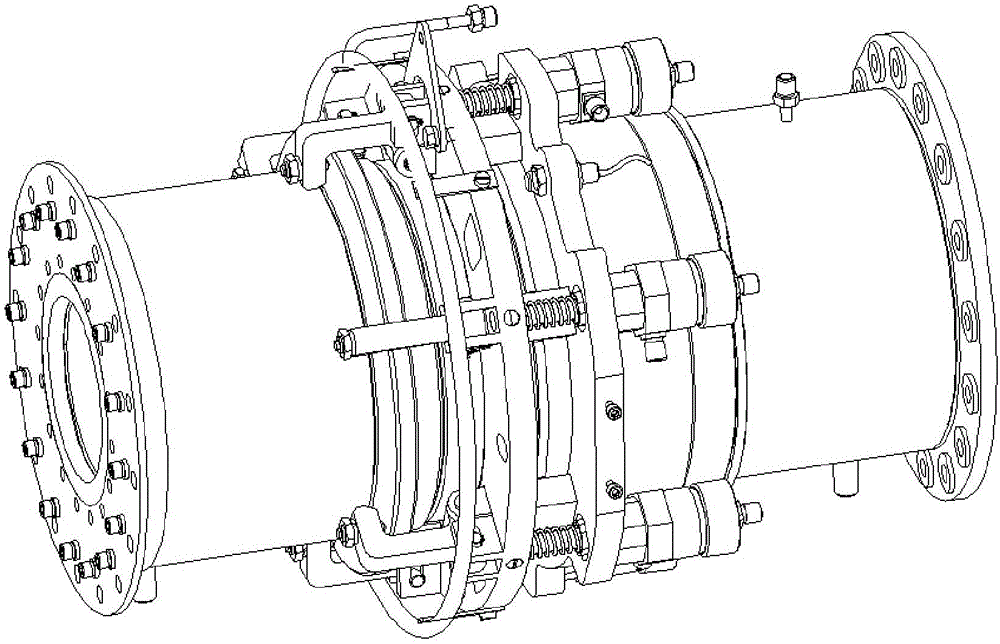

[0024] like figure 1 , image 3 As shown, the low-temperature self-sealing connector provided in this embodiment includes a ground part A and an arrow-up part B, and there is a joint surface C between the ground part A and the arrow-up part B. The low-temperature self-sealing connector is used for a low-temperature filling pipe The connection between the road and the low-temperature valve on the arrow, specifically, the ground part A includes: a medium transport chamber 4 provided in the ground outer shell 3, the medium transport chamber 4 is provided with an air passage chamber, and the air passage chamber A self-sealing control assembly is provided inside, the drive output end of the self-sealing control assembly is connected to the first end of the self-sealing cylinder 11, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com