Intelligent soot blowing method for heat engine plant boiler

A technology for thermal power plants and boilers, which is applied in the field of intelligent soot blowing of boilers in thermal power plants. The demand degree is accurate and credible, the soot blowing strategy is reasonable and effective, and the effect of ensuring reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

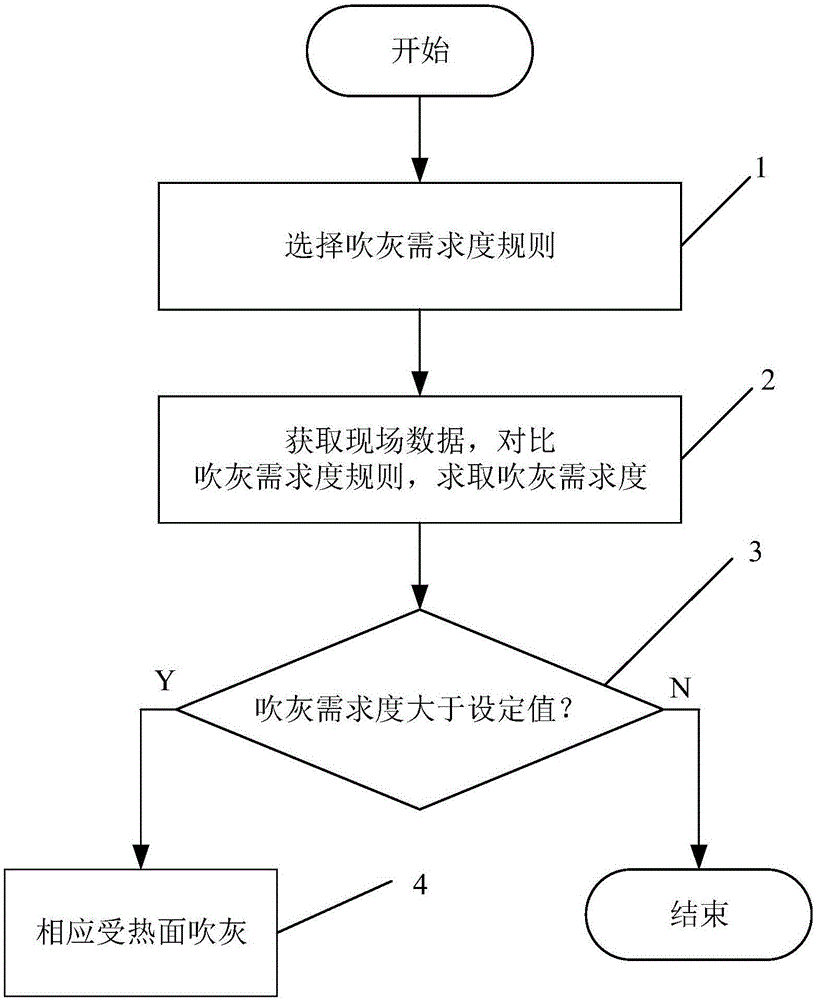

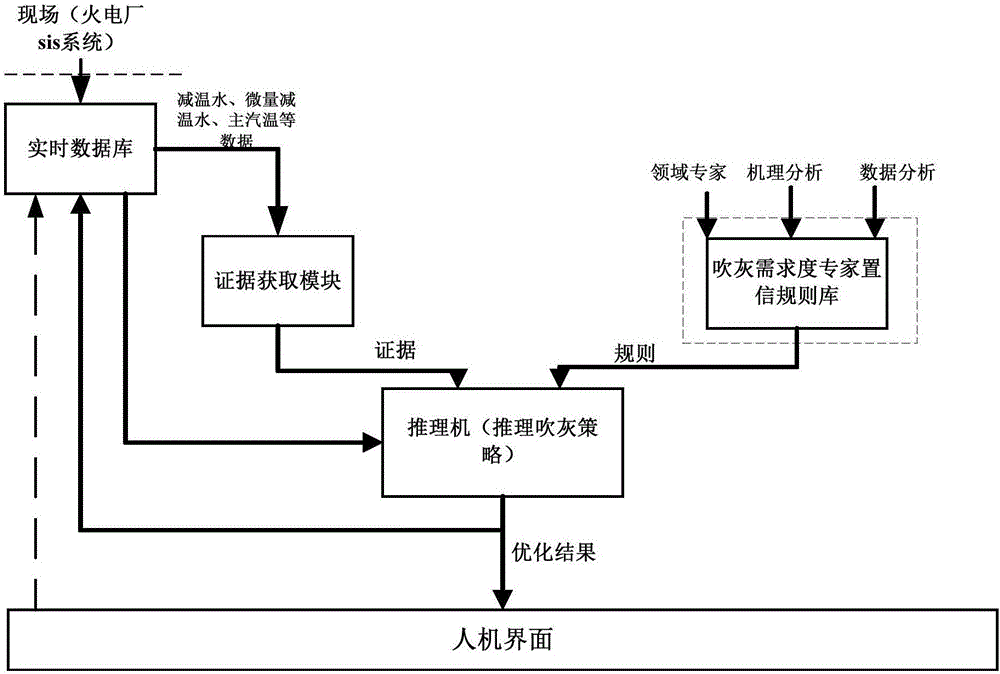

[0073] like figure 1 Shown, a thermal power plant boiler intelligent soot blowing method, the method is:

[0074] Step 1: According to the set sootblowing strategy, obtain the flue sootblowing demand degree rule and the furnace soot blowing demand degree rule respectively from the established sootblowing demand degree expert confidence rule base;

[0075] Step 2: Collect on-site boiler operation data and compare it with the rule parameters in the flue sootblowing demand degree rule and the furnace sootblowing demand degree rule, and then obtain the soot blowing demand degree of the flue and furnace heating surface;

[0076] Step 3: Determine whether the demand degree of sootblowing is greater than the set demand degree value, and the set demand degree value is 0.7. If so, perform step 4, otherwise end;

[0077] Step 4: Perform soot blowing on the corresponding heating surface in the rules according to the corresponding soot blowing requirements.

[0078] The soot blowing str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com