Sample fixing device for double-end-face grinding stone machine

A technology of a fixing device and a stone grinder, which is applied in the field of rock mechanical properties test, can solve the problems of inability to meet prismatic samples, hindering tests, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

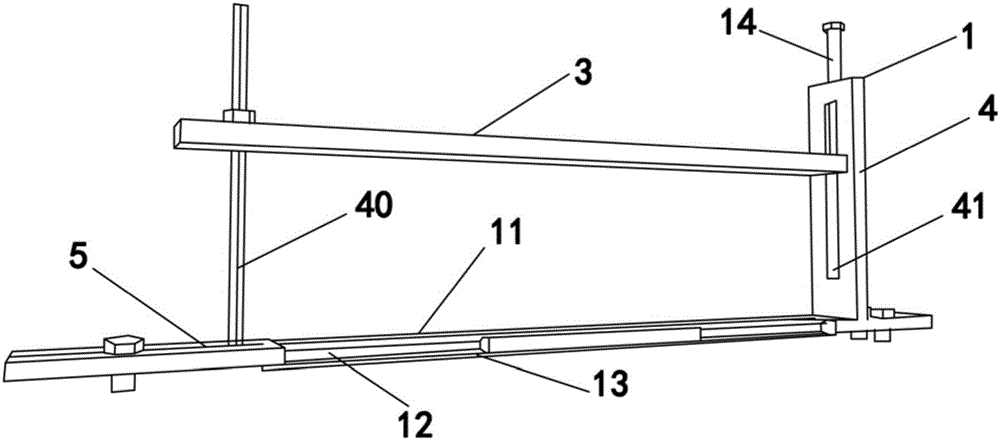

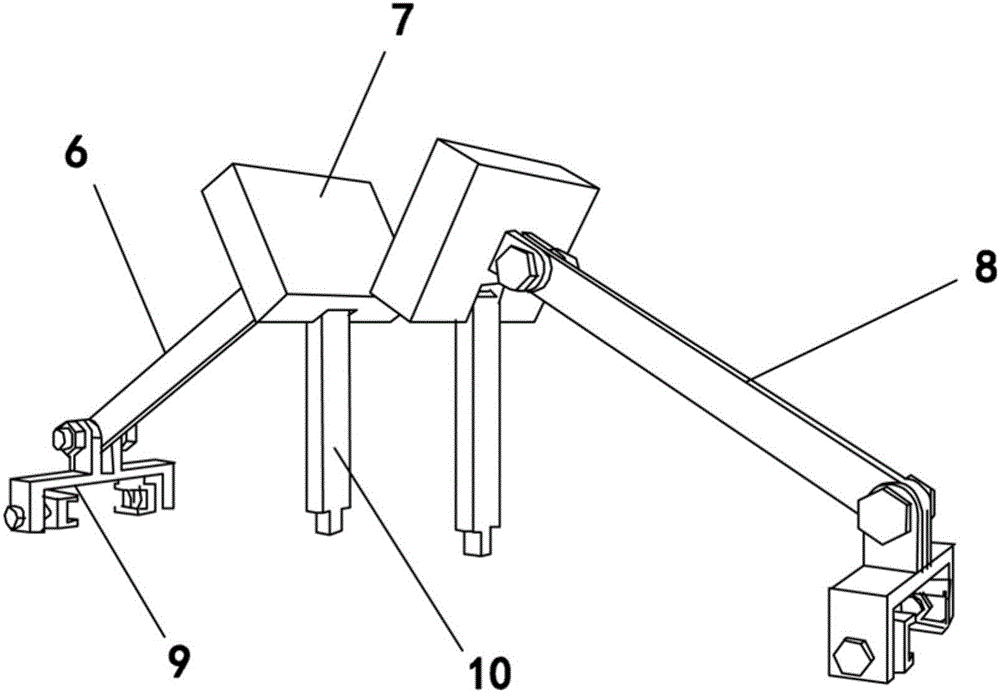

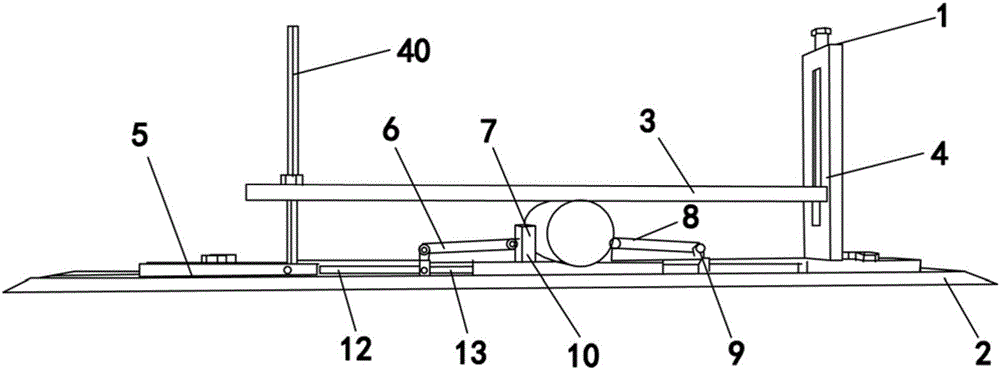

[0020] like Figure 1 to Figure 4 As shown, a sample fixing device for a double-end stone grinding machine according to the present invention includes a fixing frame 1 and a clamping device. The fixing frame 1 includes a beam plate 3, a longitudinal beam plate 4, a base 5 and a screw rod 40, and the longitudinal beam The plate 4 and the screw rod 40 are respectively fixed on both ends of the base 5, one end of the beam plate 3 is assembled with the longitudinal beam plate 4, and the other end is set correspondingly to the screw rod 40, and the clamping device is correspondingly arranged on the base 5, and the clamping device includes left and right Two sets of main clamps 6 are arranged symmetrically. The main clamps 6 include a pressure bearing plate 7 , a transmission beam 8 , a sliding winch 9 and a support rod 10 . The above cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com