Clamping device for pushout test on bamboo/wood member bolt pin connecting member

A technology for wood components and connectors, applied in the field of material testing, can solve the problems of instability, low strength, deformation of fixed ends, etc., and achieve the effects of avoiding local pressure damage, wide applicability, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

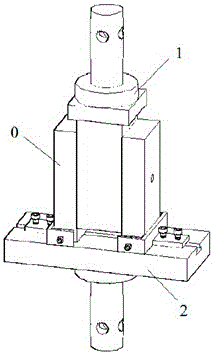

[0026] control figure 1 , during the test, the specimen 0 is placed on the lower fixture 2 and fastened, and the load is applied downward from the upper fixture 1 to carry out the test. The upper fixture 1 provides vertical compression loading for the specimen, and the lower fixture 2 provides vertical support for the specimen and lateral constraints.

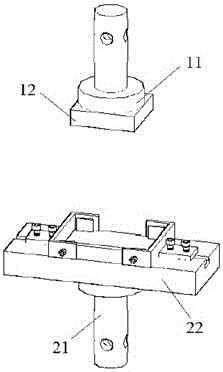

[0027] control figure 2 , The upper fixture 1 is composed of the clamping end 11 of the A testing machine and the A chuck 12, and the lower fixture 2 is formed by connecting the clamping end 21 of the B testing machine and the B chuck 22 up and down.

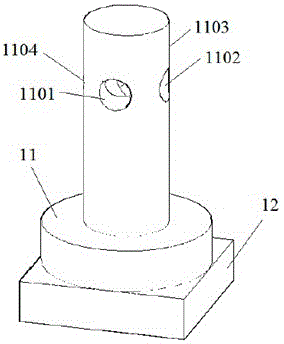

[0028] control image 3 , the clamping end 11 of the A testing machine and the A chuck 12 are connected by welding, the A bolt hole 1101, the B bolt hole 1102, the C bolt hole 1103 and the D bolt hole 1104 are used to connect the upper fixture 1 and the testing machine, according to The actual situation of the test machine is produced.

[0029] control Figure 4 , push out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com