LED backlight control method

A technology of LED backlight and backlight control, which is applied in the direction of instruments and static indicators, etc., which can solve the problems of being unable to control LED lights individually, unable to control LED lights, and unable to control accurately, so as to achieve easy mass production, easy expansion, Effects that are easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

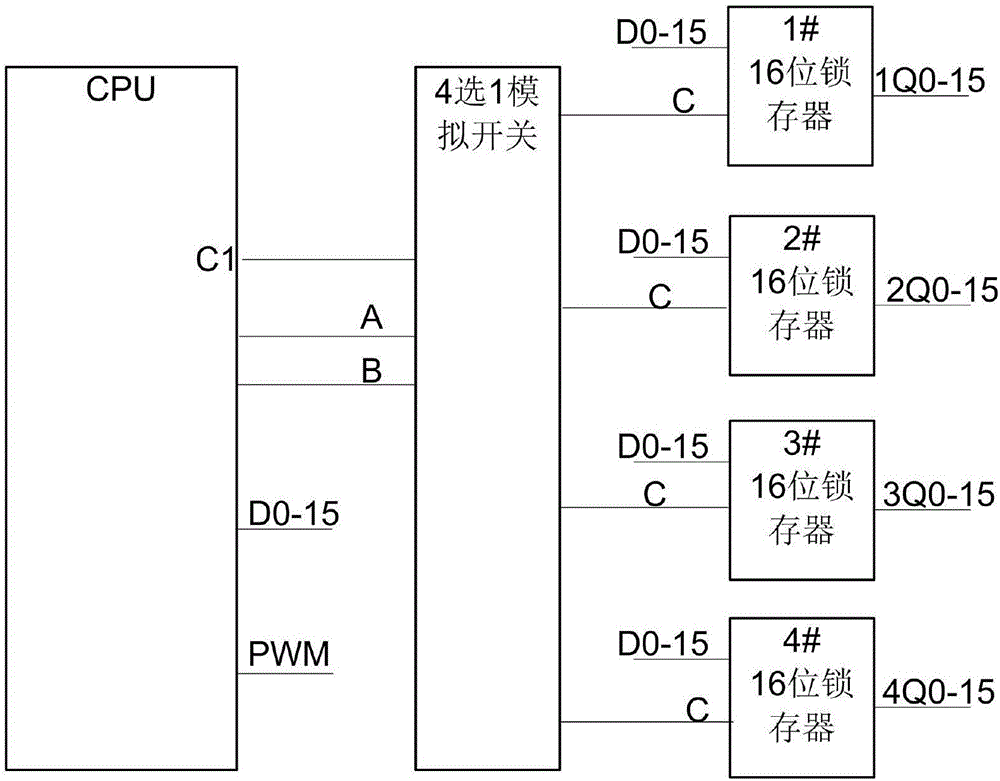

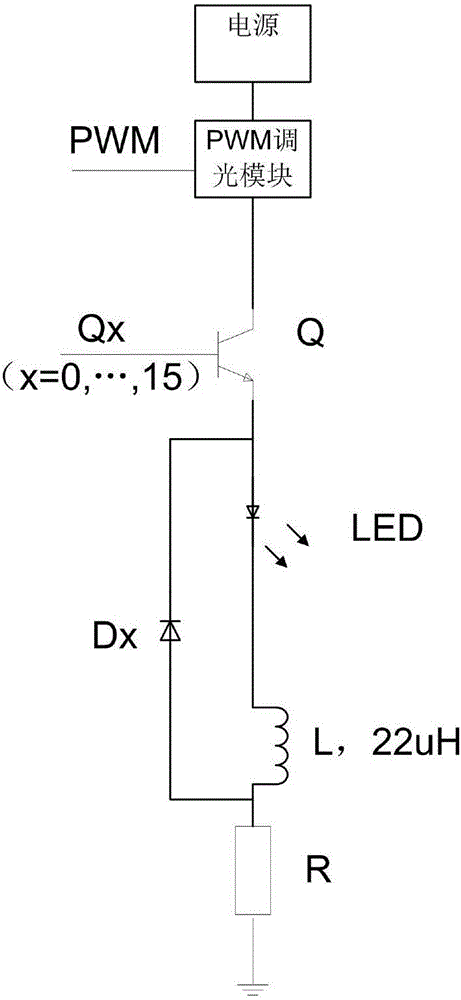

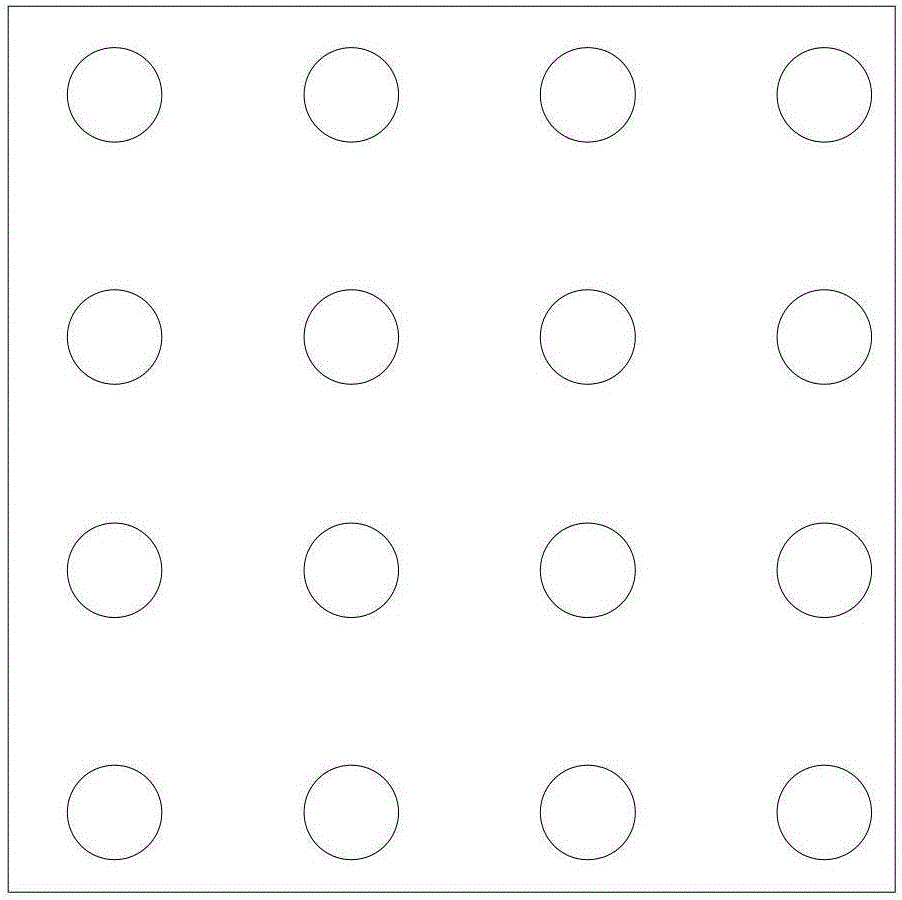

[0085] Embodiment 1: as Figures 1 to 4 , a kind of LED backlight control method, controls LED backlight; LED backlight comprises LED light-emitting array, CPU, dimming module, multi-channel analog switch and M latches; Multi-channel switch is M selects 1 analog switch; The number of channels of the multi-way switch and the number of latches are both M; M is a natural number;

[0086] The LED light-emitting array includes M*N LED light-emitting modules connected in parallel; the dimming module is connected to the power supply; multiple LED light-emitting modules are connected to the output end of the dimming module; M*N LED light-emitting modules are divided into M groups, and each group Including N LED lighting modules;

[0087] The dimming module is controlled by the CPU, and the CPU controls the output voltage or output current of the dimming module through the dimming module;

[0088] The CPU, multi-channel analog switches, latches and LED light-emitting arrays are conne...

Embodiment 2

[0106] Embodiment 2: On the basis of Embodiment 1, the LED lighting module is further improved:

[0107] Such as Figure 5-13 , the LED lighting module includes 2 LED lamps and the plug body 12; the circuit board is provided with a socket 3; the socket is provided with a jack 7 for inserting the plug body; the bottom of the jack is provided with a socket for supplying power to the plug-in light emitting module Contact 9; the plug is provided with a plug contact 4 for contacting with the socket contact;

[0108] The LED lighting module has a petal-shaped lampshade, and the petal-shaped lampshade is formed by butting four single petals 6; one end of the four single petals is connected to form the lamp bowl of the petal-shaped lampshade, and the other end of the four single petals forms the outstretched part of the lampshade. The LED light-emitting module is located at the bottom of the lamp bowl; the bottom of the lamp bowl is a plane, which is the light-emitting surface of the...

Embodiment 3

[0117] Embodiment 3: On the basis of Embodiment 1, the connection structure of the LED lighting module is further improved: as Figure 14-16 , the LED lighting module includes an LED lamp and a cylindrical insert 12;

[0118] The insert body is provided with a positive pole insert 61 and a negative pole insert 62; the outer sides of the positive pole insert and the negative pole insert are respectively provided with a recessed part with a slope; the two recesses are located at the front ends of the positive pole insert and the negative pole insert ; The positive static contact 41 and the negative static contact 42 are respectively provided in the two depressions; the circuit board is provided with a socket adapted to the plug; the socket has a jack for accommodating the plug; The positive slot and the negative slot corresponding to the positive strip and the negative strip;

[0119] In order to avoid reverse connection of positive and negative poles, the width of the positive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com