Cable chain armoring machine anti-oblique belt pulley device for vehicle

An armoring machine and belt passing technology, which is applied in the direction of cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of poor rotation of belt pulleys and affecting processing and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

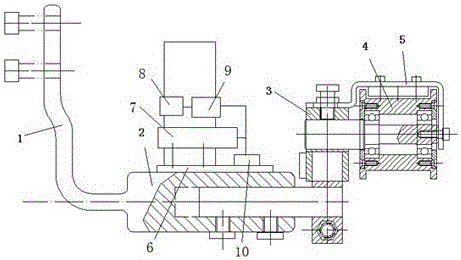

[0010] Referring to the accompanying drawings, an anti-deflection passing pulley device for a cable chain armoring machine for automobiles includes a pulley connecting rod 1, and one end of the passing pulley connecting rod 1 is provided with a pulley elbow 2, and the passing pulley The right end of the pulley elbow 2 is fixedly installed with a pulley bracket 3, the pulley bracket 3 is rotatably mounted with a pulley 4, and the side wall of the pulley elbow 2 is fixed with a strain gauge 6, The strain gauge 6 is connected to a data memory 7, the data memory 7 is connected to a microprocessor 8, the microprocessor 8 is connected to a temperature sensor 9, and the temperature sensor 9 is fixed on one side of the strain gauge 6, and the microprocessor Humidity and air pressure sensors 10 are also provided on the device 8, and the microprocessor 8 processes and analyzes the signals transmitted by the temperature sensor, humidity and air pressure sensors to generate self-compensati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com