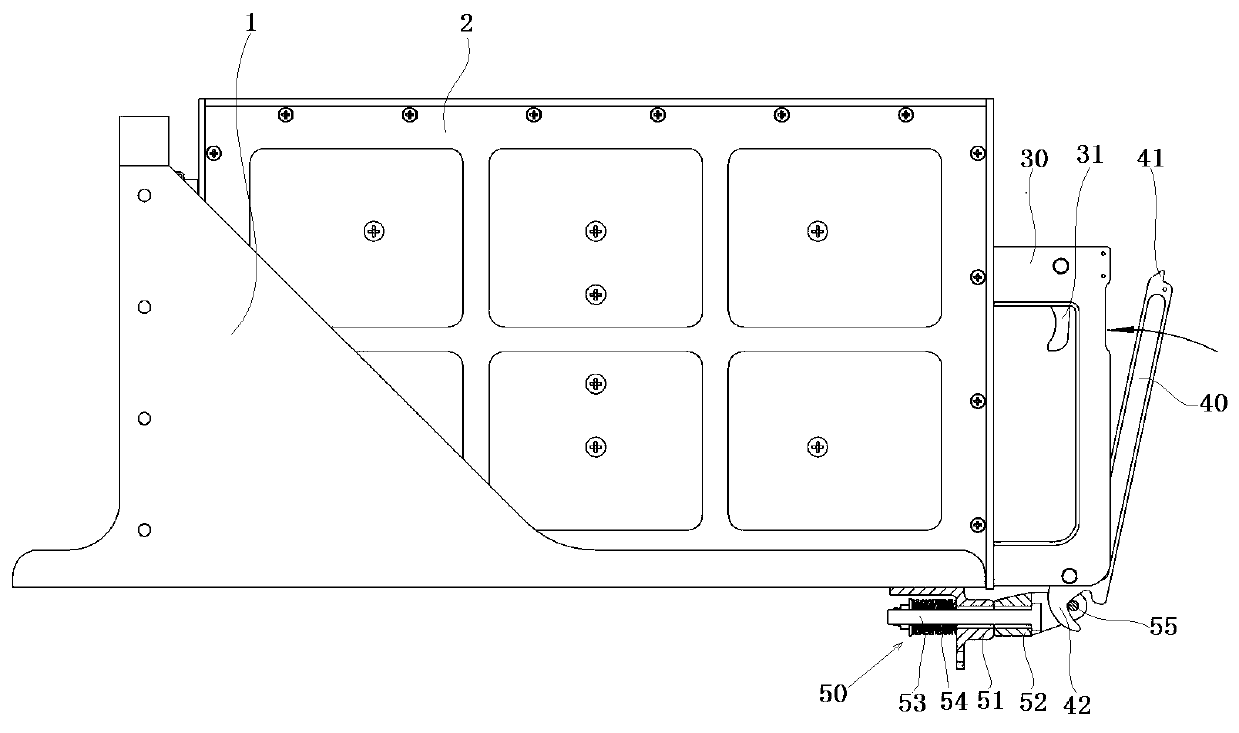

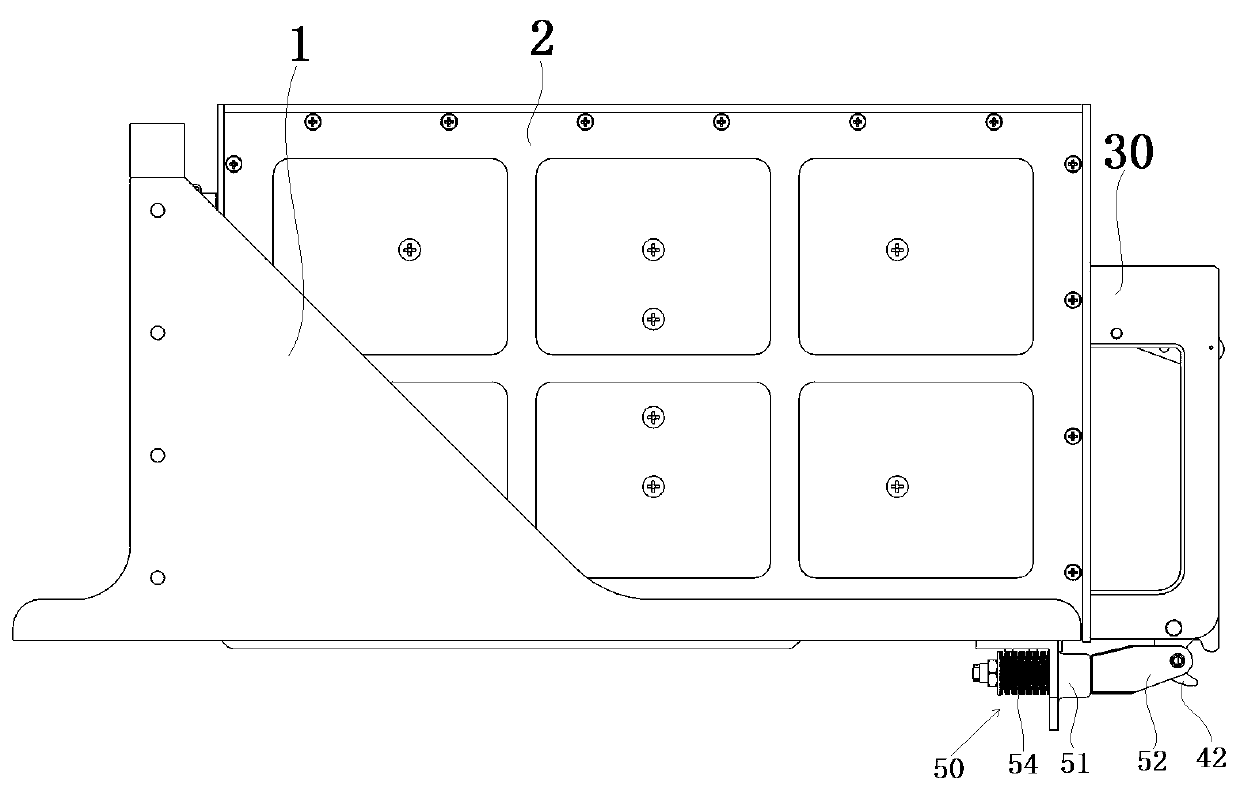

Anti-loosening locking device and the chassis bracket and cabinet using the locking device

A locking device and unlocking technology, which is used in the installation of support structures, clamping/extracting devices, etc., can solve the problems of easy loosening of the locking device and poor locking effect, and achieve the effect of eliminating contact gaps and avoiding loosening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

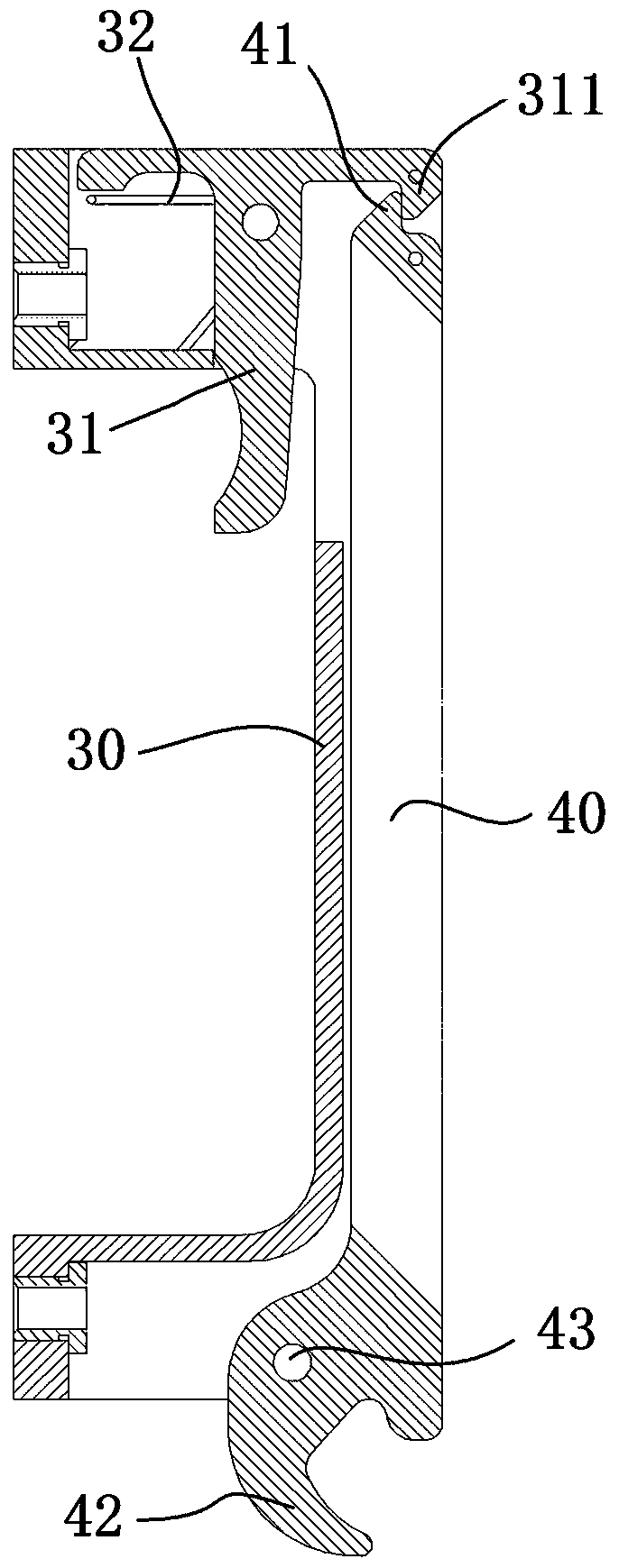

[0037] Embodiment 2 of the present invention: Different from Embodiment 1, the elastic member is arranged between the locking member and the first stop structure of the connecting pin. Of course, the protruding end of the connecting pin can also extend from the side of the locking member. out,.

Embodiment 3

[0038] Embodiment 3 of the present invention: different from the embodiment, an extension section is provided on the locking member, and the extension section guides and slides with the connecting hole on the base of the locking device. Of course, it can also be provided on the base of the locking device extension.

[0039] Embodiment 4 of the present invention: Different from Embodiment 1, the connecting pin is directly slidably matched with the locking member and the base of the locking device, and no bushing is provided to reduce the number of components.

[0040] In the specific embodiment of the chassis bracket of the present invention, the structure of the chassis bracket is the same as the chassis bracket in the embodiment of the cabinet above, and will not be repeated here.

[0041] A specific embodiment of the anti-loosening lock device of the present invention, the structure of the anti-loosening lock device is the same as that of the lock device in the embodiment of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com