Telescopic pressing nail capable of being positioned

A telescopic, limit block technology, applied in the direction of cooling/ventilation/heating transformation, can solve the problems of increasing the board space, easily touching the components on the board, and device damage, so as to avoid damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

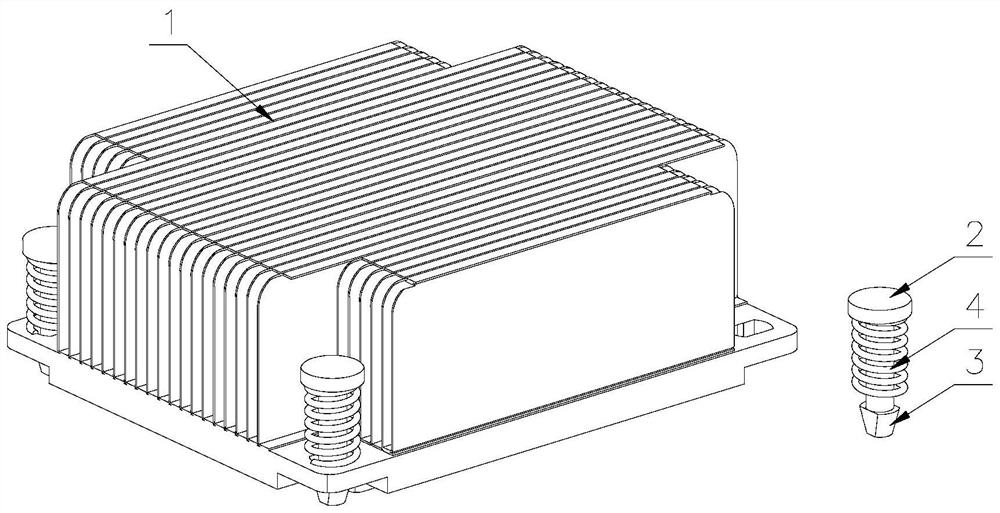

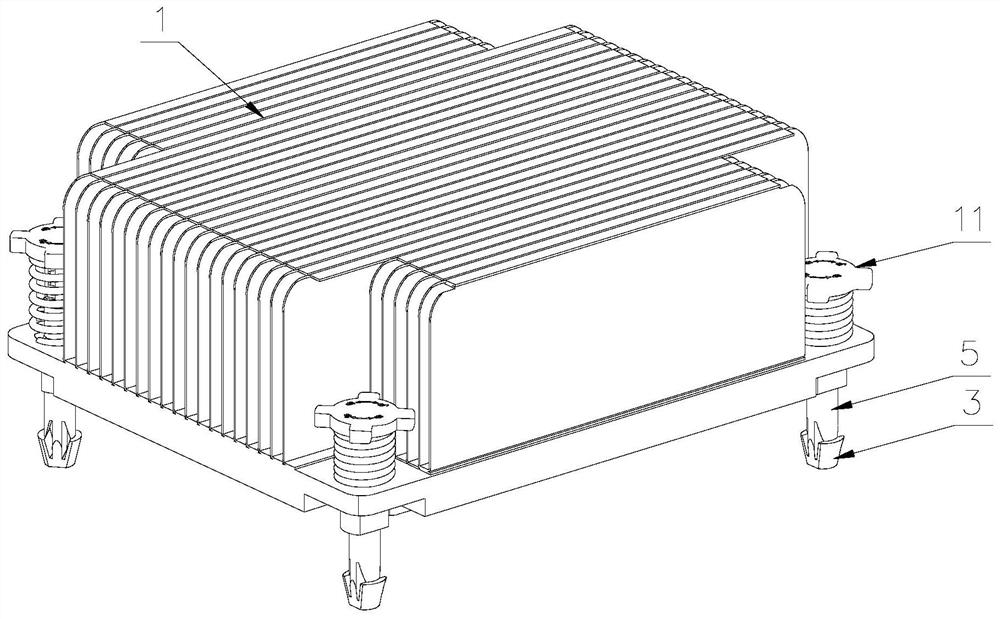

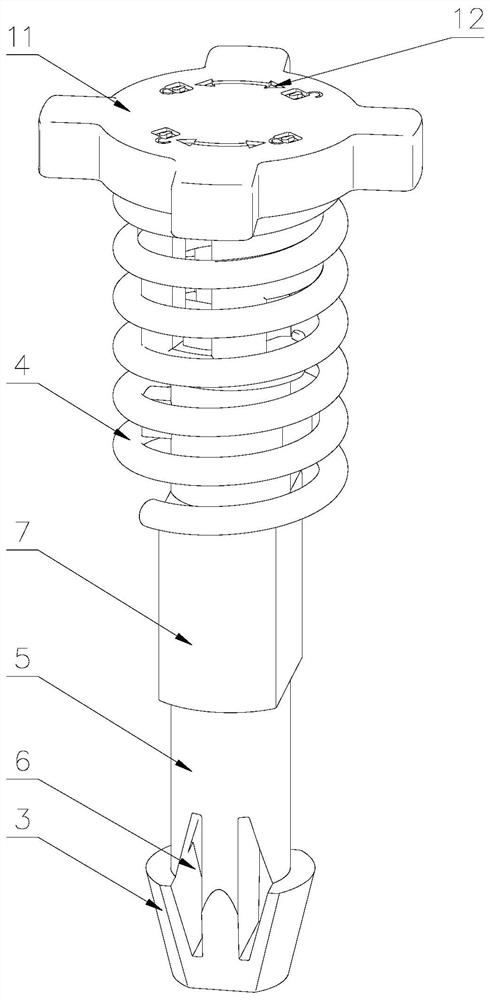

Embodiment 1

[0038] Such as Figure 2-4 , Figure 7 As shown, a positionable telescopic push nail includes an insertion rod 5, the lower end of the insertion rod 5 is provided with an extrusion head 3 for guiding and locking with the PCB hole, and the upper end of the insertion rod 5 is provided with The first limit block 9, the outer side of the upper part of the insertion rod 5 is provided with a column cover 13, the column cover 13 is a hollow cylindrical structure, and the upper part of the column cover 13 is provided with a screw cap 11, which is convenient for the column cover 13 to rotate and lock When force is applied, a number of first slideways 14 are provided on the side wall of the column sleeve 13, and the first stop block 9 is engaged in the first slideway 14 with a gap, and the upper end of the first slideway 14 runs through A first horizontal engaging portion 15 is connected to the ground, and the first horizontal engaging portion 15 is vertically arranged with the first s...

Embodiment 2

[0049] The difference from Example 1 is that, as Figure 5-6 As shown, in this embodiment, the spring 4 is arranged inside the column sleeve 13, and the lower end of the spring 4 is connected to the top of the insertion rod 5; the spring 4 is hidden inside the column sleeve 13 to strengthen the push button aesthetics, and avoid the influence of the spring 4 on the internal circuit of the server.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com