Pneumatic brake cylinder and brake clamp unit

A pneumatic brake and cylinder technology, applied in the field of rail transit, can solve problems such as alleviating gap instability, and achieve the effects of improving debugging efficiency, eliminating errors, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

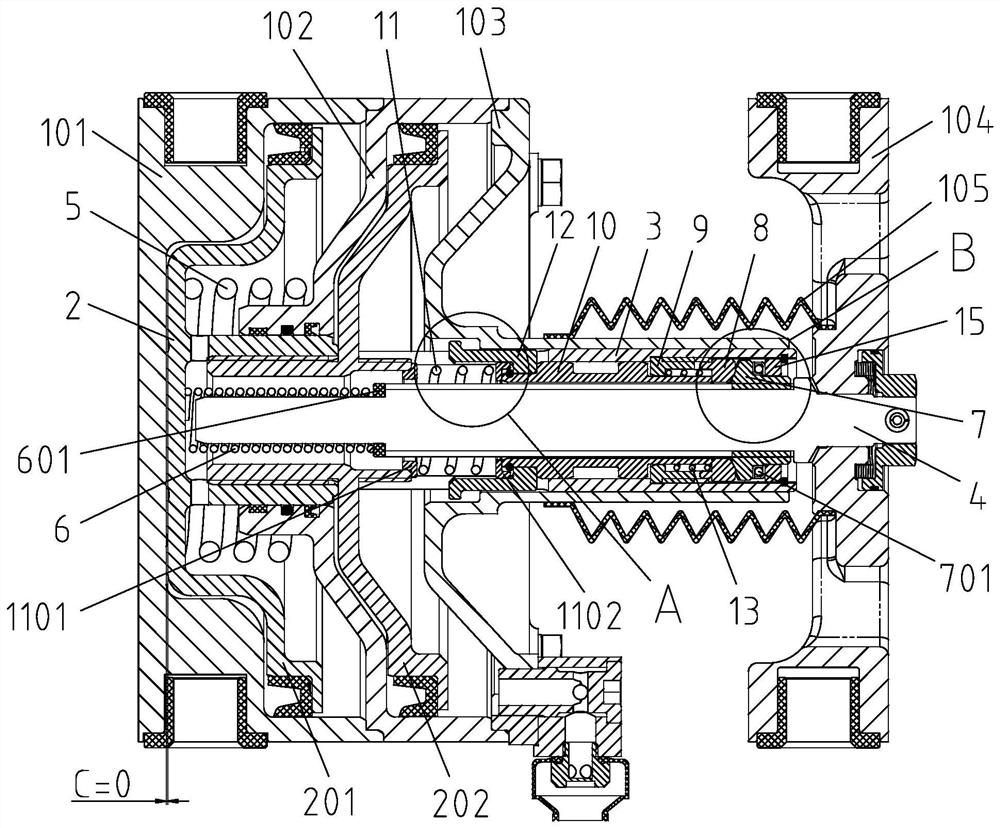

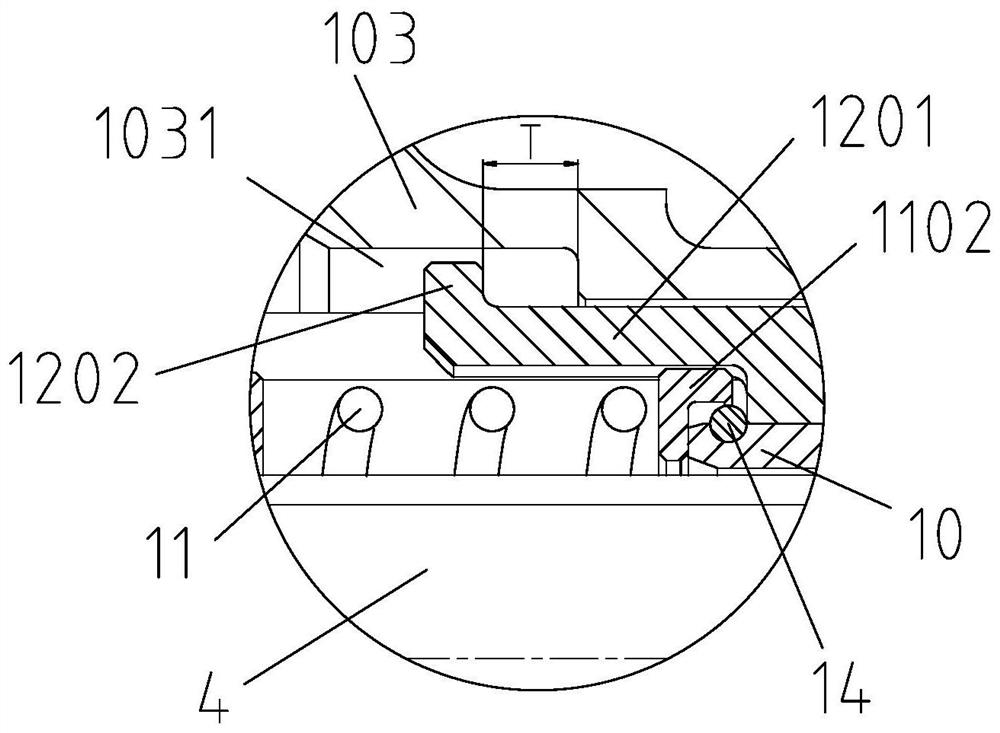

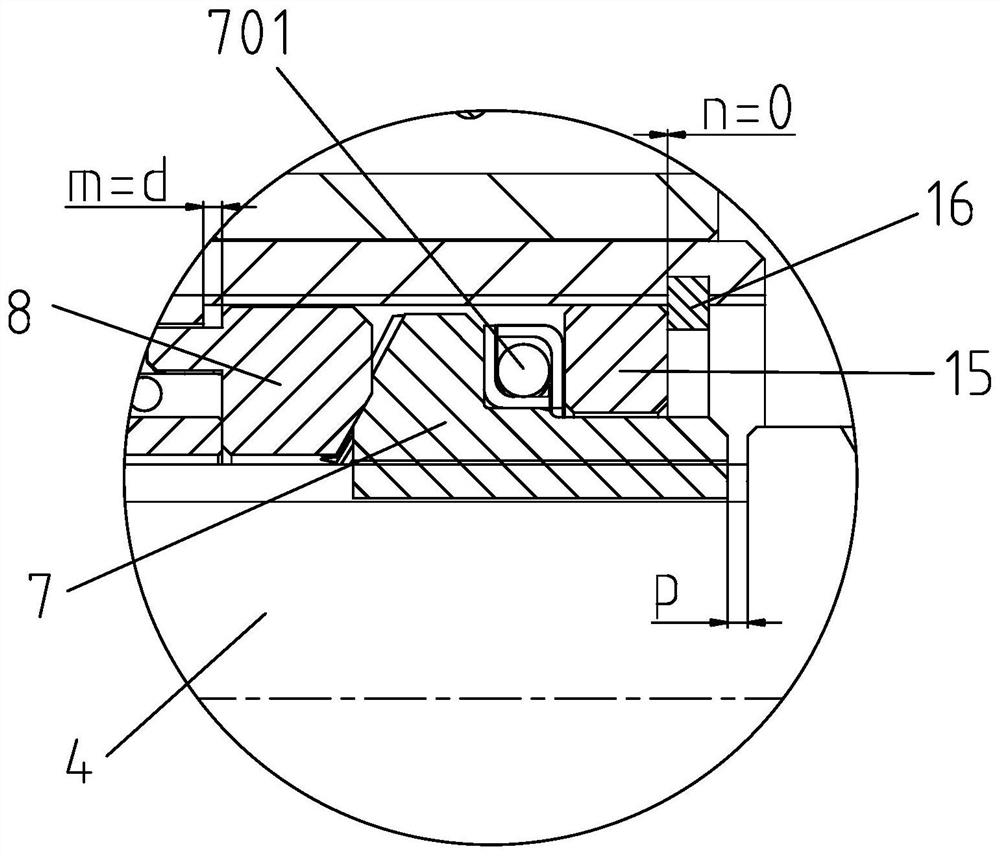

[0110] Example 1: Participation Figure 1 to Figure 3 , a pneumatic brake cylinder, including a cylinder body and a front end assembly 104, the cylinder body includes a rear cover assembly 101, an intermediate assembly 102 and a front cover assembly 103 connected in sequence, and the outside of the sleeve of the front cover assembly 103 is provided with A dustproof cover 105, one end of the dustproof cover 105 is connected to the front cover assembly 103, and one end is connected to the front end assembly 104; the cylinder body is provided with:

[0111] Piston assembly 2;

[0112] The piston sleeve 3 is connected with the piston assembly 2;

[0113] The lead screw 4 is arranged in the piston sleeve 3, and one end is connected with the front end assembly 104;

[0114] The relief spring 5 is arranged between the intermediate assembly 102 and the piston assembly 2;

[0115] Adjust the spring 6, one end is crimped to the piston assembly 2, and the other end is crimped to the l...

Embodiment 2

[0150] Example 2: see Figure 21 , a brake caliper unit, including a caliper assembly 17 and a pneumatic brake cylinder 18, the pneumatic brake cylinder 18 adopts the pneumatic brake cylinder described in Embodiment 1, and the pneumatic brake cylinder 18 is connected to the clip through a connecting bolt 20 The clamp arm 19 of the clamp assembly 17 is hinged.

[0151] In this embodiment, the brake caliper unit is installed on the bogie frame of the rail transit vehicle, and the brake disc is held tightly by the brake pad, and the kinetic energy of the train is converted into heat consumption by the friction between the brake pad holder and the brake disc. Dispersion, to achieve the effect of deceleration or parking.

Embodiment 3

[0152] Embodiment 3: see Figure 22 , a pneumatic brake cylinder, including a cylinder body and a front end assembly 104, the cylinder body includes a rear cover assembly 101, an intermediate assembly 102 and a front cover assembly 103 connected in sequence, and the outside of the sleeve of the front cover assembly 103 is provided with A dustproof cover 105, one end of the dustproof cover 105 is connected to the front cover assembly 103, and one end is connected to the front end assembly 104; the cylinder body is provided with:

[0153] Piston assembly 2;

[0154] The piston sleeve 3 is connected with the piston assembly 2;

[0155] The lead screw 4 is arranged in the piston sleeve 3, and one end is connected with the front end assembly 104;

[0156]The relief spring 5 is arranged between the intermediate assembly 102 and the piston assembly 2;

[0157] The adjustment spring 6 is arranged between the front cover assembly 103 and the front end assembly 104;

[0158] Gap adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com