Moisturizing assembly for hair straightener

A hair straightener and moisturizing technology, applied in applications, hair curlers, hairdressing equipment, etc., can solve problems such as tarnishing, static electricity, dryness, etc., and achieve the effect of eliminating design, strong heat-resistant and moisturizing function, and good user experience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

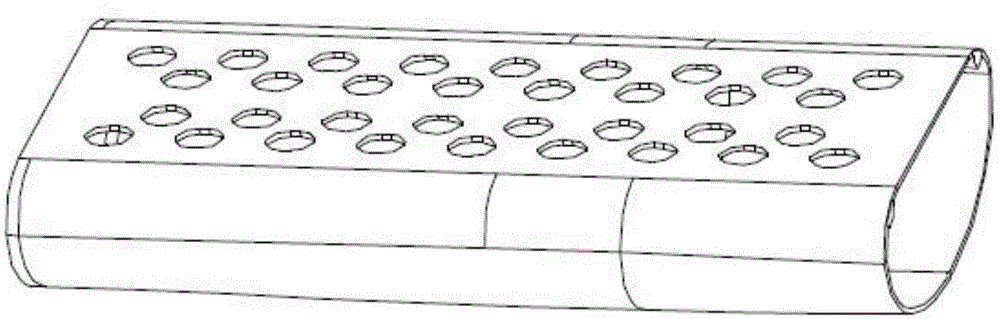

[0034] Such as figure 1 As shown, a hair straightener hydrating component includes a silica gel layer covering the heating module in the hair straightener body;

[0035] Wherein, the silica gel layer is provided with a through hole, and a spacer layer is provided between the silica gel layer and the heating module.

[0036] The diameter of the through hole is 4-6mm.

[0037] The thickness of the spacer layer is 0.3-0.5mm.

[0038] The thickness of the silica gel layer is 0.5-0.8mm.

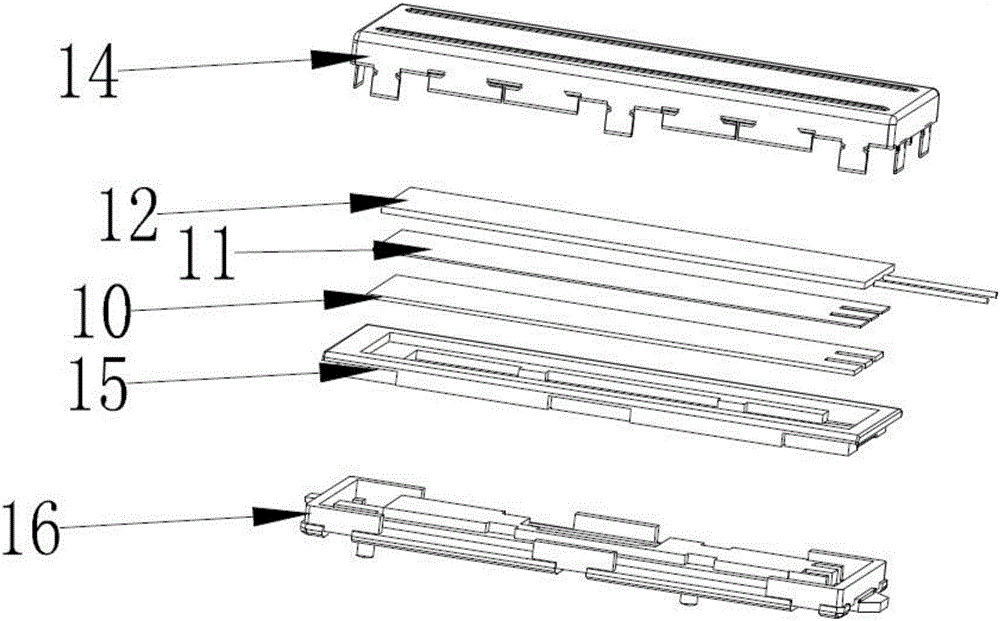

[0039] Such as figure 2 As shown, the heating module includes a base, a working board 14, a heating sheet 12, a heat insulating sheet 11, and a silica gel pad 10, and the base is provided with a container; the silica gel pad is placed in the container; The heat insulating sheet is embedded on the silica gel pad; the heating sheet is placed on the heat insulating sheet; the working board is in a zigzag shape, matched with the base, and the heating sheet, heat insulating sheet, and silica gel p...

Embodiment 2

[0045] A hydrating component for a hair straightener, comprising a silica gel layer covering the heating module in the hair straightener body;

[0046] Wherein, the silica gel layer is provided with a through hole, and a spacer layer is provided between the silica gel layer and the heating module.

[0047] The diameter of the through hole is 4-6mm.

[0048] The thickness of the spacer layer is 0.3-0.5mm.

[0049] The thickness of the silica gel layer is 0.5-0.8mm.

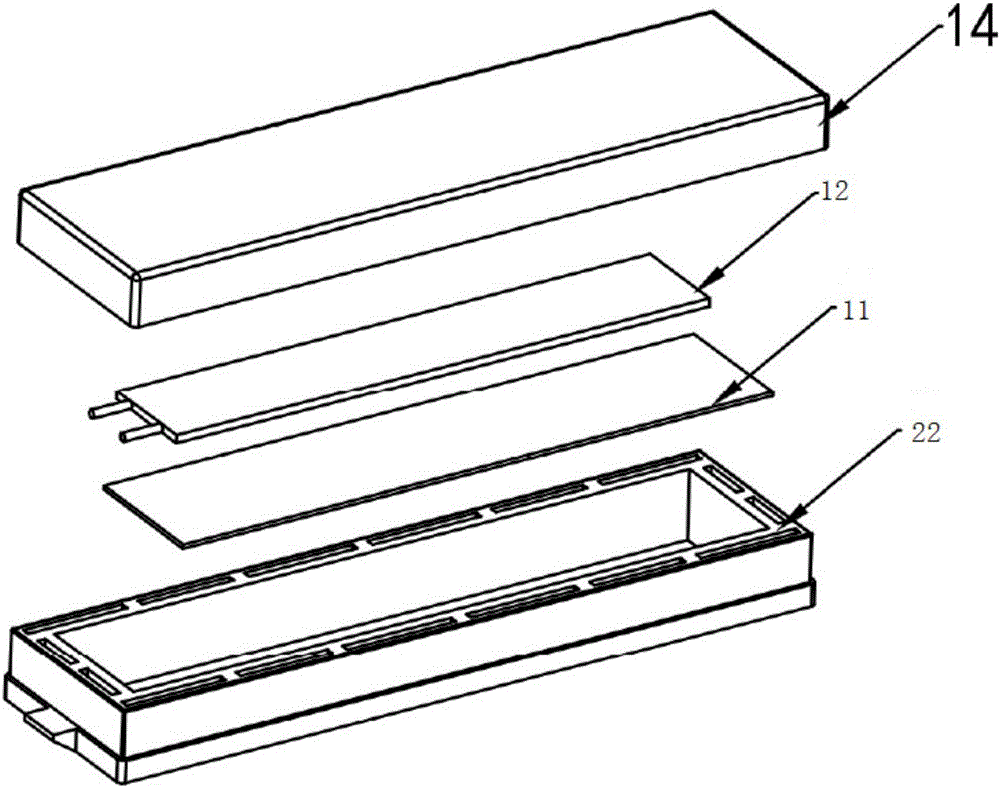

[0050] Such as image 3 as shown,

[0051] The heating module includes a base 22, a working board 14, a heating sheet 12, and a heat insulating sheet 11. The heat insulating sheet is embedded on the base; the heating sheet is placed on the heat insulating sheet; the working board and the base The seat fits, so that the spacer plate and the heating plate are sandwiched between the working plate and the base;

[0052] The heating sheet fits closely with the bottom surface of the working plate.

[0053] The heat...

Embodiment 3

[0058] Such as figure 1 As shown, a hair straightener hydrating component includes a silica gel layer covering the heating module in the hair straightener body;

[0059] Wherein, the silica gel layer is provided with a through hole, and a spacer layer is provided between the silica gel layer and the heating module.

[0060] The diameter of the through hole is 4-6mm.

[0061] The thickness of the spacer layer is 0.3-0.5mm.

[0062] The thickness of the silica gel layer is 0.5-0.8mm.

[0063] Such as Figure 4 As shown, the heating module includes a working board 14, an external fixing frame 20, a substrate 21, a silica gel pad 10, a heating sheet 12, and a heat insulating sheet 11, and the substrate is clamped in the external fixing frame; the silica gel pad is placed on the substrate above; the heat insulating sheet is placed on the silica gel pad; the heating sheet is placed on the heat insulating sheet; the working board is clamped in the outer fixing frame, the upper surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com