Filter plate structure for filtering machine

A filter plate and filter machine technology, applied in the direction of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of inability to squeeze in place, reduced effect, etc., and achieve good extrusion effect and good water sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

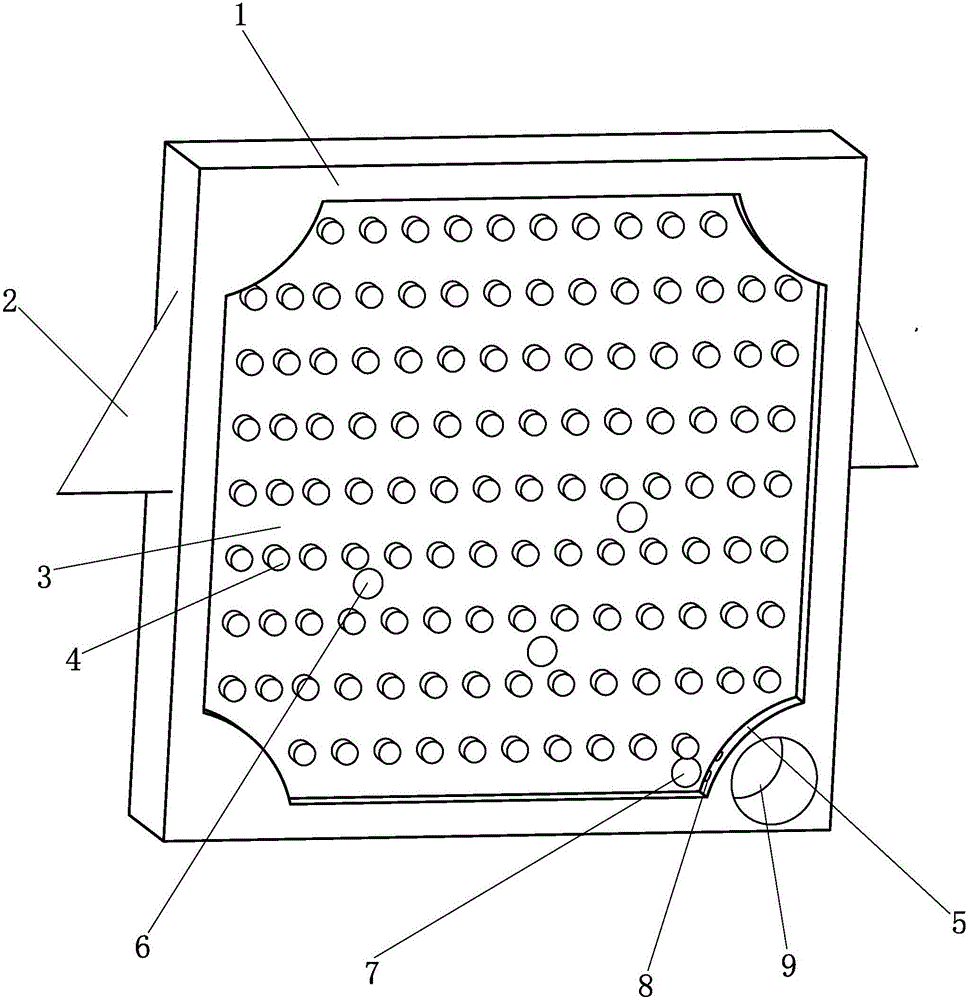

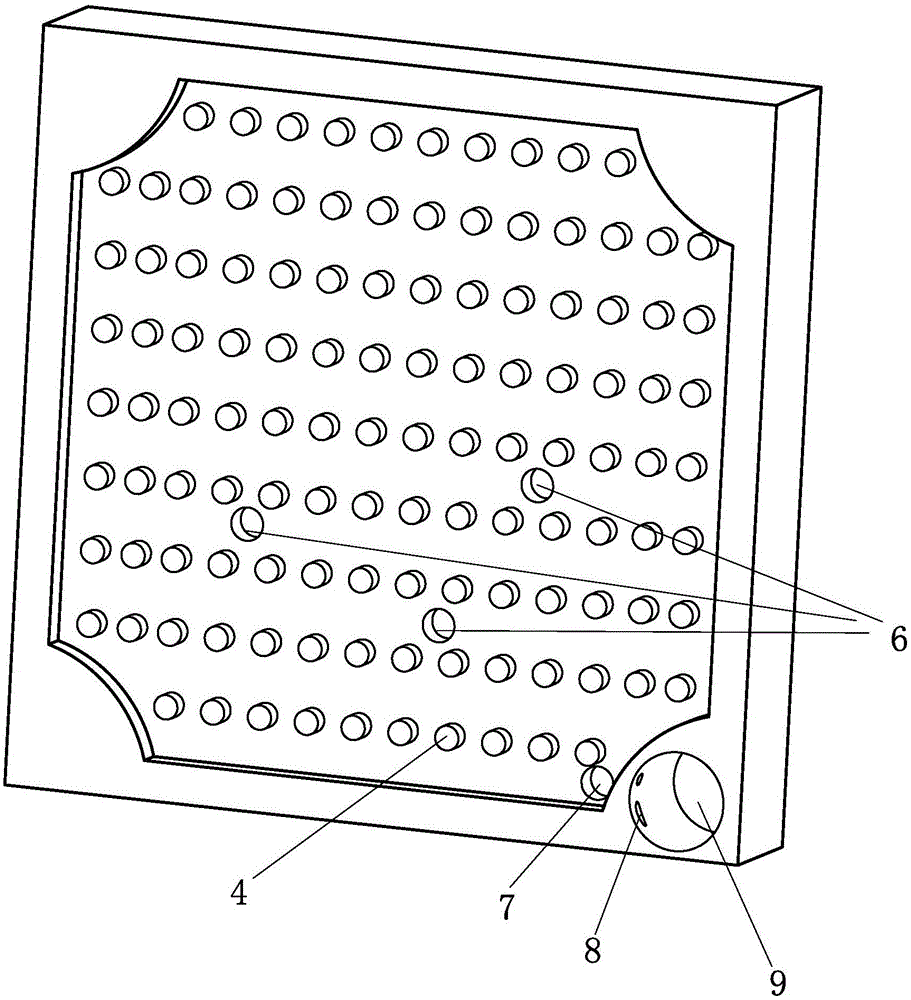

[0015] figure 1 , 2 As shown, the present invention includes a filter frame 1 with an outer ring, a filter plate body 3 is arranged in the filter frame 1, support arms 2 are arranged on the left and right sides of the filter frame 1, and both sides of the filter plate body 3 are covered by filter cloth. When squeezed, sewage infiltrates into the filter cloth and enters the filter plate body 3, and the waste residue is left on the filter cloth.

[0016] The upper row of the double-sided filter plate body 3 is provided with several convex columns 4, and the column feet between the convex columns 4 are gaps for diverting sewage, and the sewage can flow down from the gaps. The height of the convex column 4 is smaller than th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com