Super adhering wearing layer roadway maintenance method

A wear layer, high-viscosity technology, applied in the field of preventive maintenance treatment, ultra-stick wear layer pavement maintenance, can solve the problems of long open traffic time, insufficient road surface adsorption, prone to peeling, etc., to improve the water sealing performance of the road surface, The effect of increasing pavement texture and friction coefficient and improving comprehensive mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

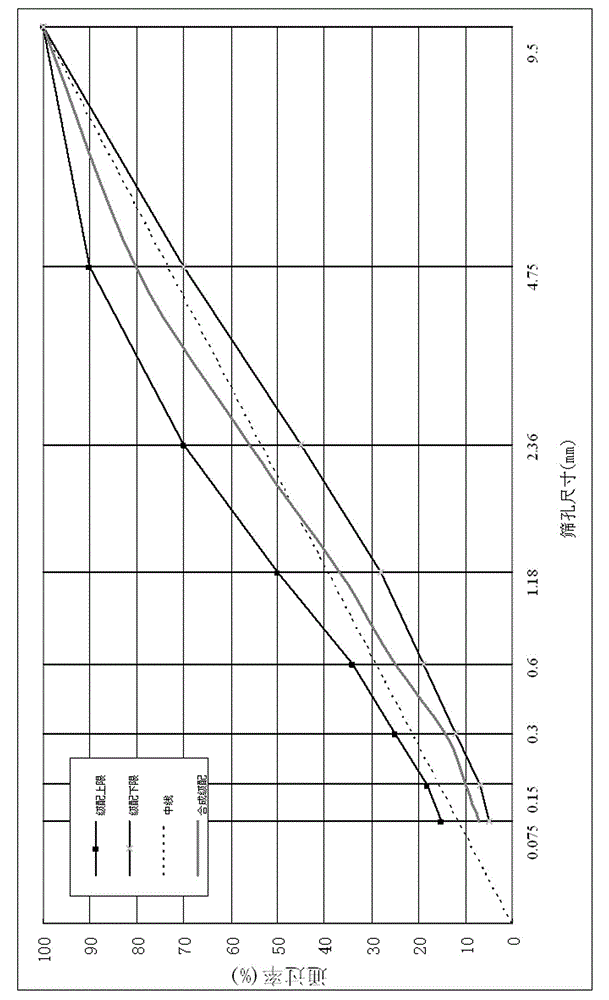

[0019] refer to figure 1 , the present invention super sticky wearing layer pavement maintenance method comprises the steps:

[0020] 1) Spray high-viscosity modified emulsified asphalt;

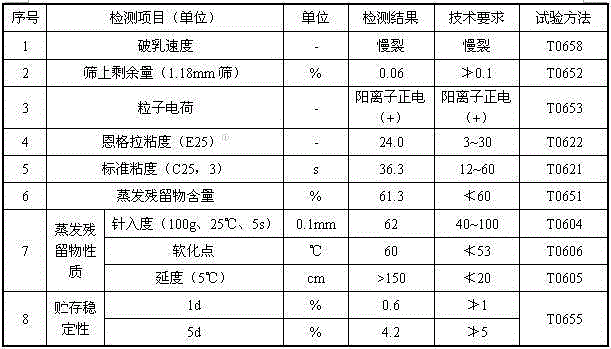

[0021] Spray the high-viscosity modified emulsified asphalt that meets the technical requirements evenly on the original road surface, and the amount of spraying is generally 0.15kg / m2 of pure asphalt 2 ~0.3kg / m 2 Control, high viscosity modified emulsified asphalt performance indicators are shown in Table 1 below.

[0022] Table 1 Test results of high viscosity modified asphalt

[0023]

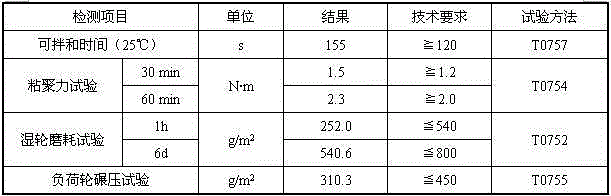

[0024] 2) Preparation of super viscous wear layer mixture

[0025] Refer to attached figure 1 , the super-viscous wearing layer mixture used in this step is composed of coarse aggregate, fine aggregate, modified emulsified asphalt for mixing, fiber, water and filler, and the aggregate includes coarse aggregate and fine aggregate; coarse aggregate The specifications of the aggregate are 3~5mm and 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com