Bonding layer synchronizing drainage asphalt pavement construction process

A technology of drainage asphalt and construction technology, which can be applied to cohesive pavement paved on site, roads, roads, etc., which can solve the problems of prolonging the construction period, exceeding 24 hours, and reducing construction efficiency, so as to improve construction efficiency, facilitate construction, and The effect of saving construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

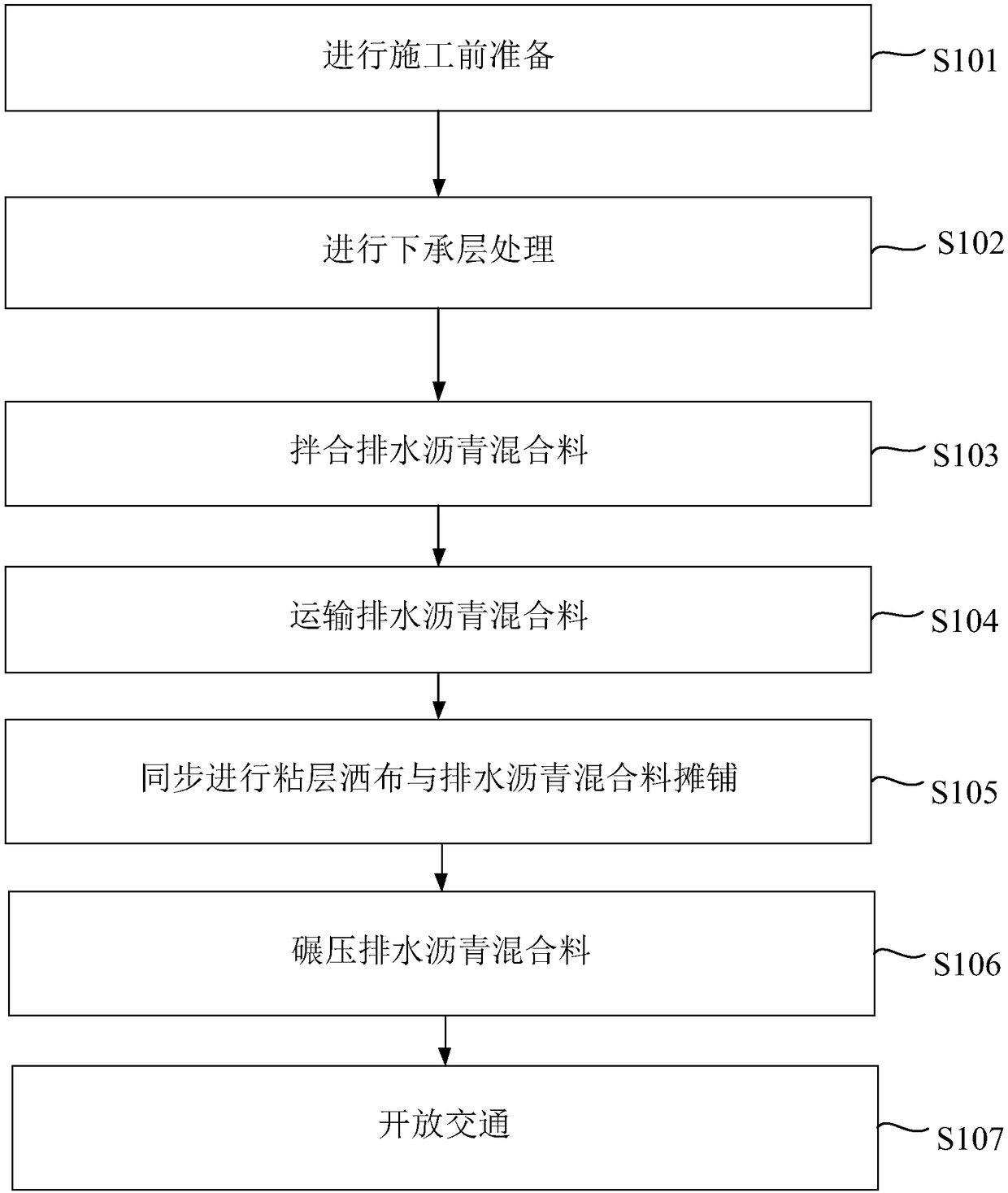

[0038] figure 1 It shows a construction flow chart of a construction process of a drainage asphalt pavement with a simultaneous adhesion layer according to an embodiment of the present invention. The construction process can include:

[0039] In step 101, pre-construction preparations are performed, including raw material preparation and construction machinery preparation;

[0040] In step 102, the treatment of the underlying layer is carried out, including the investigation of the disease of the underlying layer, and different treatment methods are adopted for each type of disease investigated, and a special sweeper is used to clean the road surface to ensure that the road surface is clean and free of debris;

[0041] In step 103, mixing the drained asphalt mixture includes strictly controlling the production temperature of the mixture, and the discharge temperature is 170-185°C, and the mixing process adopts a dry method or a wet method;

[0042] In step 104, the transportation of ...

Embodiment 2

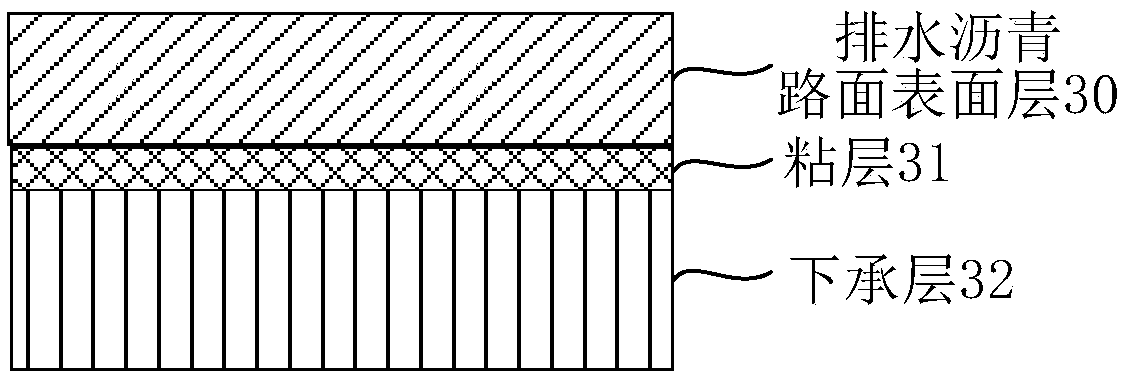

[0050] image 3 It shows a structure diagram of a drainage asphalt pavement obtained by a drainage asphalt pavement construction process with a synchronous adhesive layer according to an embodiment of the present invention.

[0051] The pavement structure includes a drainage asphalt surface layer 30, an adhesive layer 31, and a lower bearing layer 32 in order from top to bottom. The drainage asphalt surface layer 30 is an ultra-thin wear layer with a thickness of 1.5-3 cm, or the drainage asphalt surface layer 30 is an asphalt pavement upper layer with a thickness of 3-5 cm.

[0052] In a possible implementation manner, the drainage asphalt surface layer 30 is paved with drainage asphalt mixture, with a porosity ranging from 18 to 25%, and a water permeability coefficient not less than 5000 ml / min.

[0053] In a possible implementation manner, the adhesive layer 31 includes one of SBS modified emulsified asphalt or SBR modified emulsified asphalt, and the spreading amount is 0.3 to 0...

application example 1

[0064] The application example 1 of the present invention provides a construction process of a cohesive layer synchronous drainage asphalt pavement, which is used in the preventive maintenance of old highways, see image 3 , The pavement structure from top to bottom is the drainage asphalt surface layer 30, the sticky layer 31, and the underlying layer 32. The drainage asphalt surface layer 30 is an ultra-thin wear layer with a thickness of 1.5cm. The underlying layer 32 is the original pavement of the old road. .

[0065] Wherein, the drainage asphalt surface layer 30 is paved with PAC-05 drainage asphalt mixture, the porosity is 19.1%, the water permeability is 5217ml / min, and the gradation range is shown in Table 1 below.

[0066] Table 1

[0067] Types of

9.5

4.75

2.36

1.18

0.6

0.3

0.15

0.075

PA-05

100

15~50

8~30

5~12

4~10

4~8

4~7

3~6

[0068] Wherein, the adhesive layer 31 is SBS modified emulsified asphalt, the spraying temperature is 70°C, the solid content is 60%, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com