Automatic alloy strip surface cleaning mechanism

A technology for automatic cleaning and alloy strips, which is applied in the direction of cleaning methods using tools, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems that alloy strips affect the surface quality of alloy strips, affect production efficiency, and have high labor intensity. It is convenient to clean or replace wool felt, realize automatic production, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention and its beneficial technical effects will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

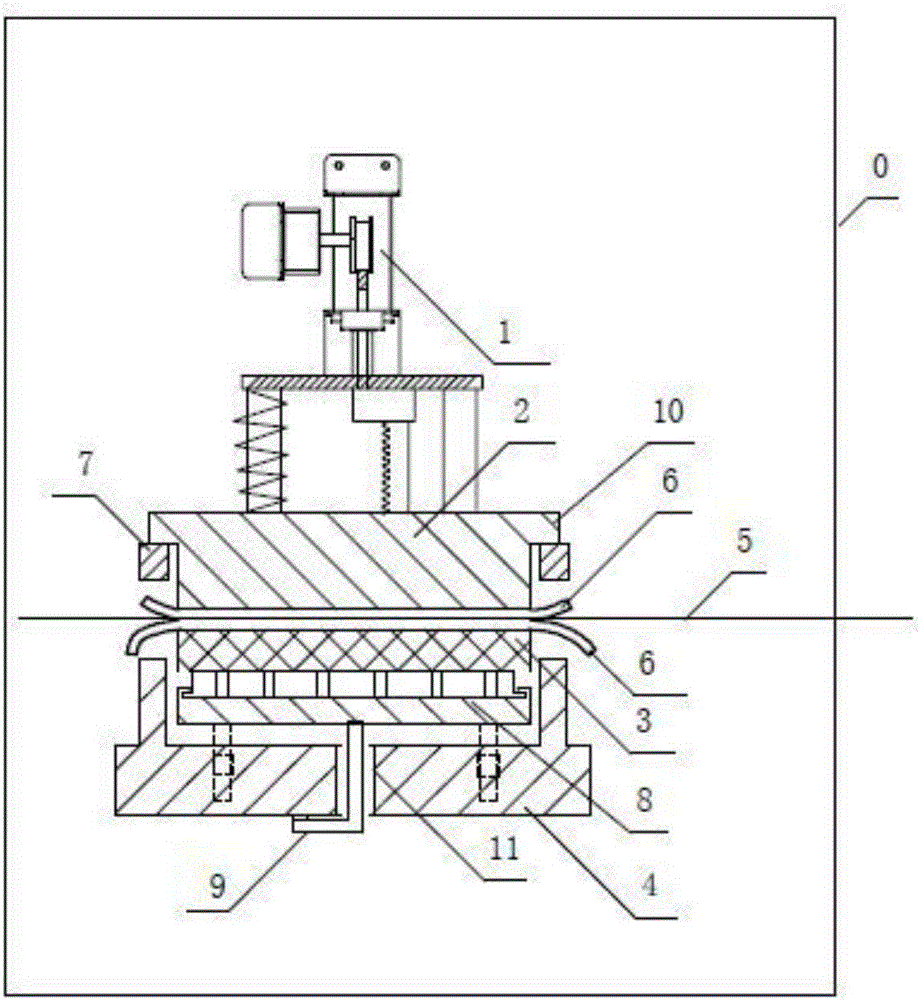

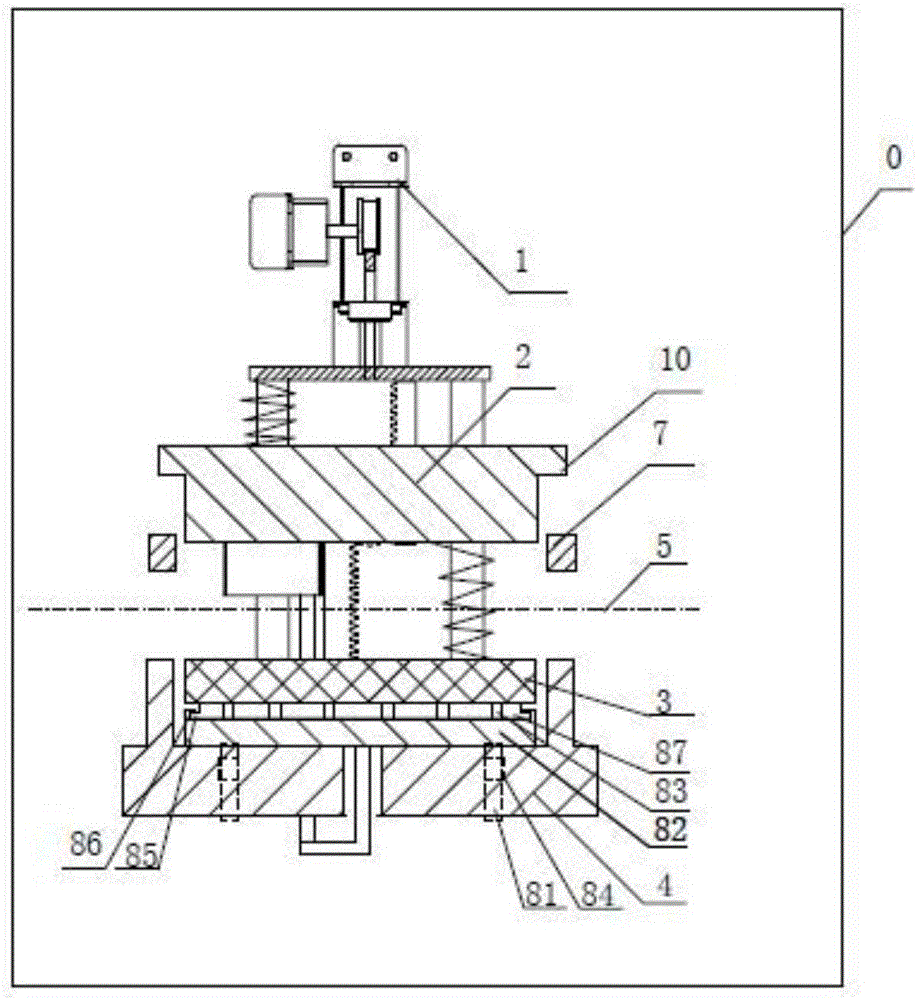

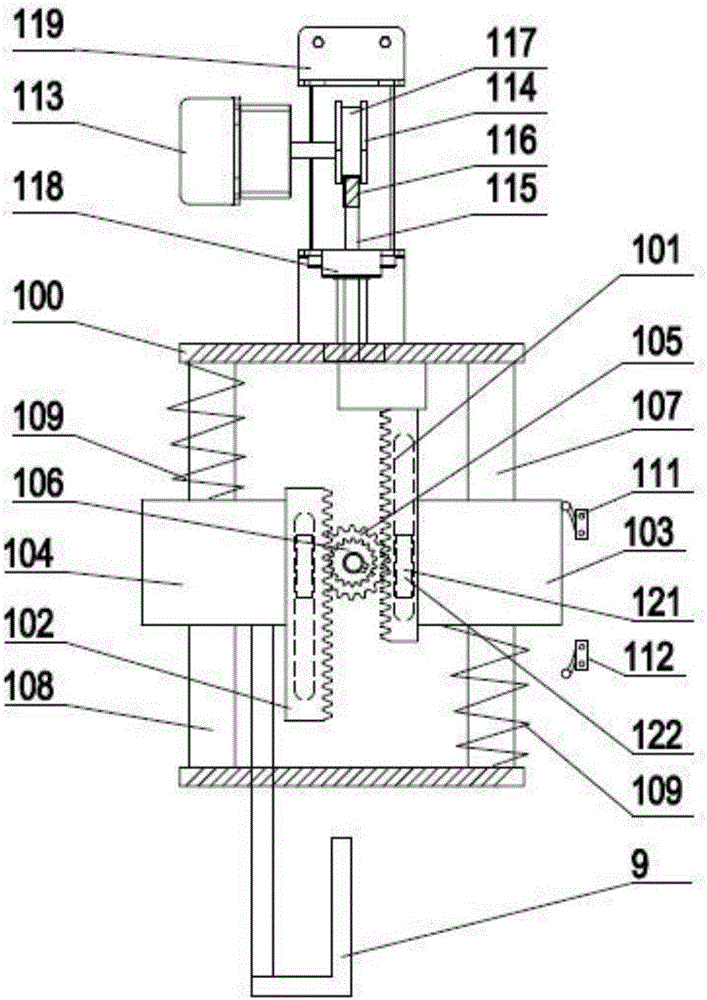

[0019] see Figure 1 ~ Figure 3 , the belt surface automatic cleaning mechanism of the alloy belt includes a frame 0 for installing various components, an upper pressing plate 2 and a lower pressing plate 3 for pressing the alloy belt in it from the upper and lower sides, and a support seat 4 for fixing the lower pressing plate 3; the upper pressing plate The top of 2 is connected with a synchronous variable-speed linkage mechanism 1 that controls the reverse opening of the upper pressing plate 2 and the lower pressing plate 3 or that they are pressed against each other. An elastic rubber composite plate is provided under the lower pressing plate 3; an adjustment hole 11 is provided at the bottom of the support seat 4; among them, The synchronous different-speed linkage mechanism comprises an inst...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap