Terminal block automatic screw locking machine

A terminal block and screw locking technology, which is applied in the field of automatic processing equipment, can solve the problems of low efficiency, high labor cost, and time-consuming, and achieve high efficiency and realize the effect of unmanned operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

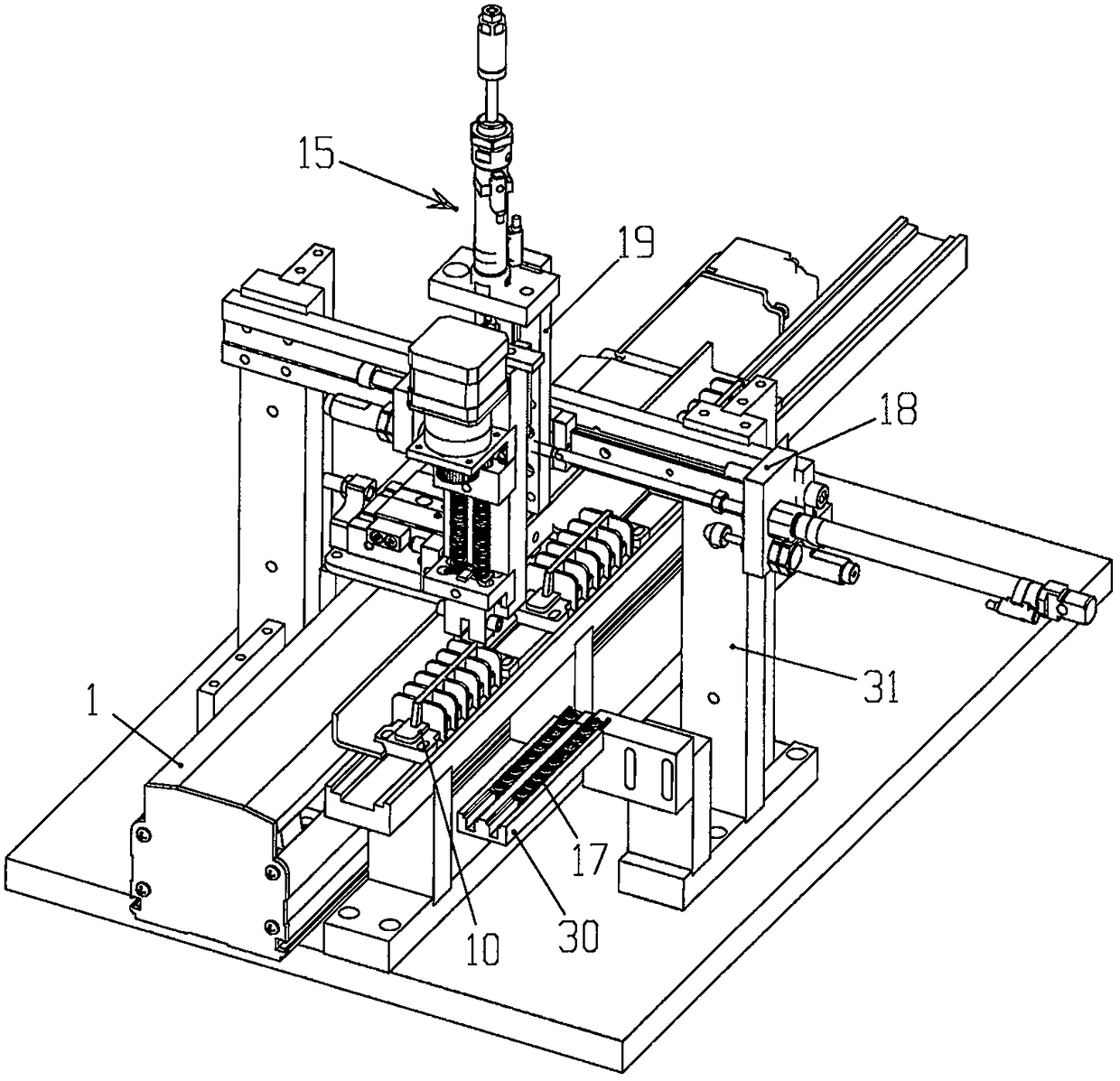

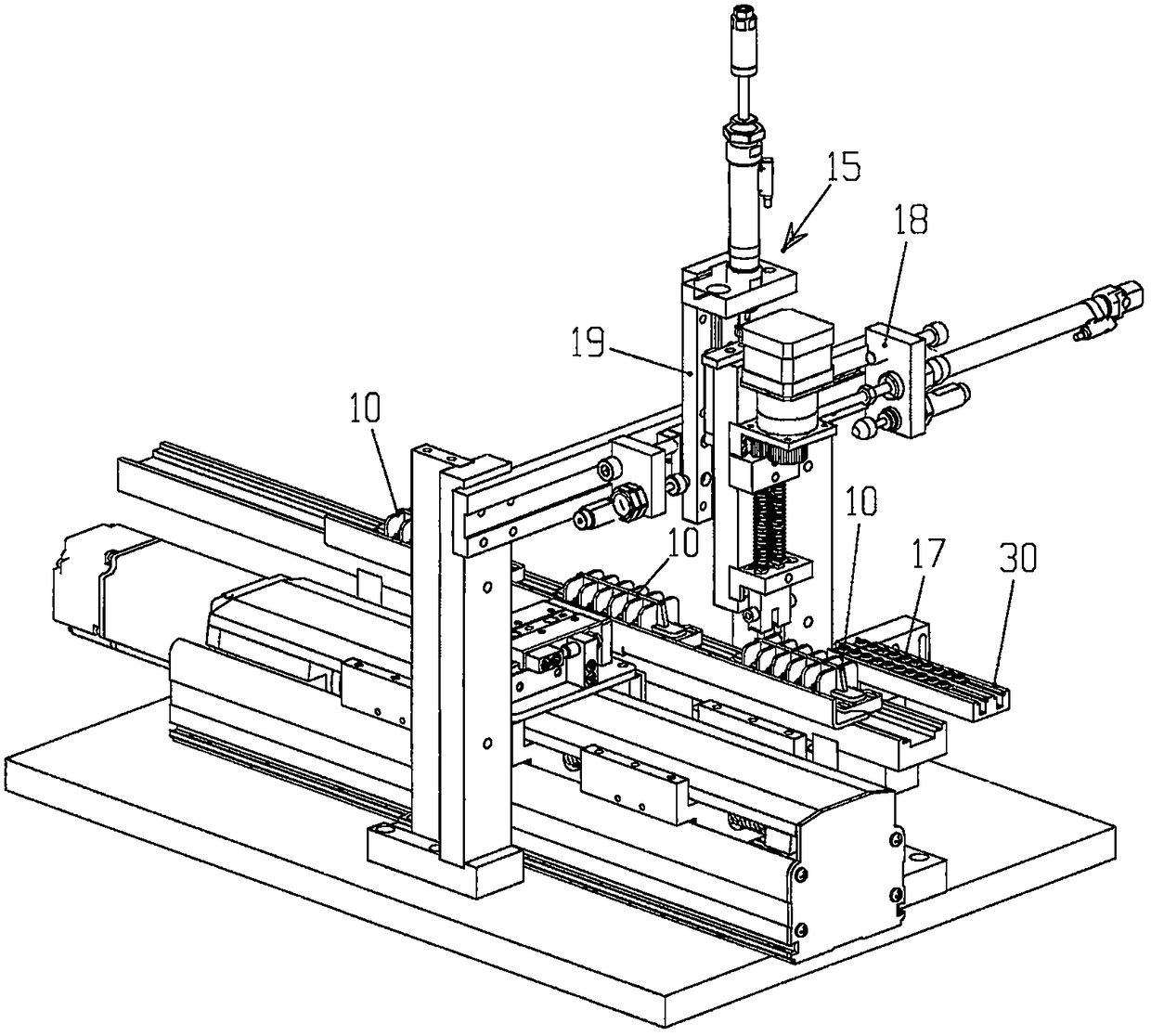

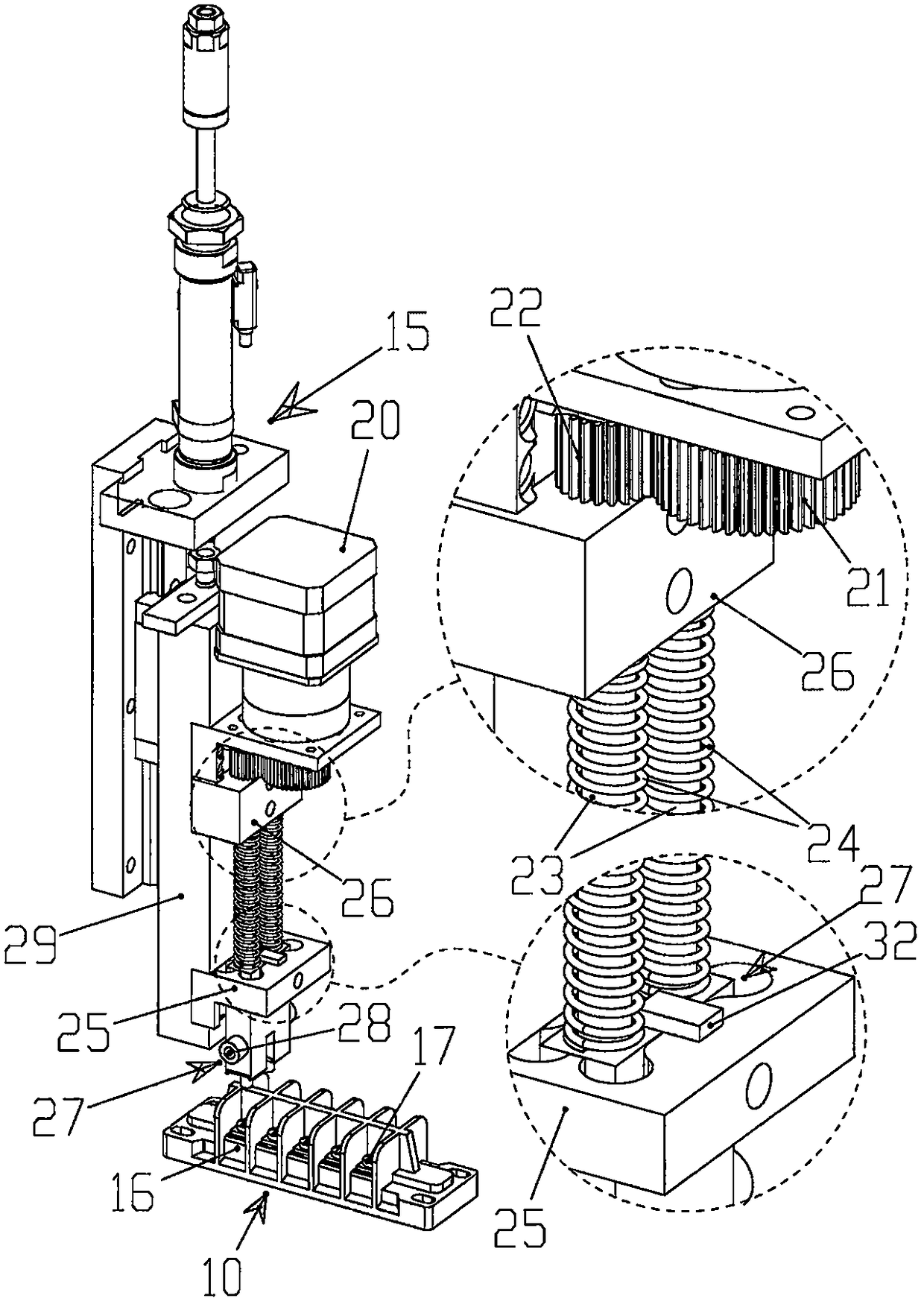

[0032] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. As mentioned above, the present invention provides a fully automatic screw locking machine for terminal blocks, which is used in the automatic production process of terminal blocks. The automatic screwdriver realizes automatic feeding and locking of screws, and the single-axis robot system realizes automatic delivery of terminal blocks. ; The automatic screw locking machine for the terminal block of the present invention realizes the automatic bit-by-bit feeding of the terminal block, so that the assembly of the terminal block obtains automatic and unmanned production efficiency.

[0033] figure 1 , 2 It is a structural schematic diagram of the automatic locking screw machine of the wiring row of the present invention, image 3 It is a schematic diagram of the structure of the fully automatic screw locking machine for the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com