An automatic feeding system for pvc pipe cutting

A PVC pipe and automatic feeding technology, which is applied in metal processing and other directions, can solve the problems of cutting machine feeding troubles, manually pushing PVC pipes, etc., and achieve the effect of improving cutting efficiency and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

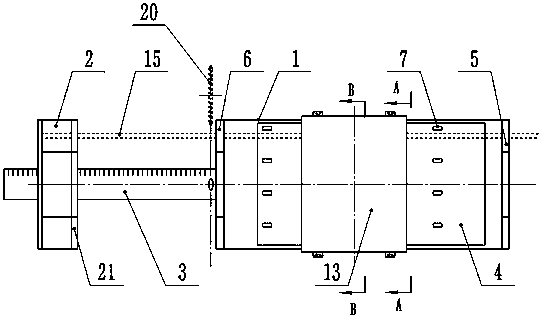

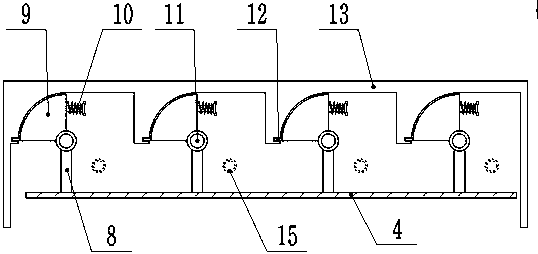

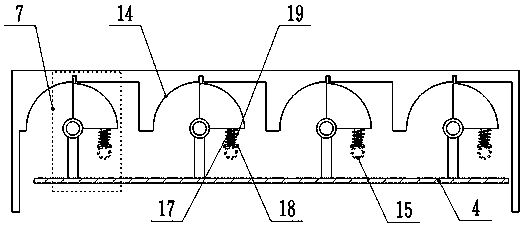

[0025] Such as Figure 1-4 As shown, the present invention is a kind of automatic feeding system that is used for PVC pipe cutting, comprises feeding frame 1, PVC pipe length positioning frame 2 and guide rail 3, is provided with conveyor belt 4 on feeding frame 1, and conveyor belt 4 passes roller and motor Driven to rotate, a row of front guide holes 5 and rear guide holes 6 are correspondingly provided on the feed frame 1 at the front and rear ends of the conveyor belt 4, and a PVC pipe traction device 7 is provided on the conveyor belt 4 corresponding to the front guide holes 5 and the rear guide holes 6 , Such as Figure 2-3 As shown, the PVC pipe traction device 7 includes a connecting rod 8, a 1 / 4 circle rotating compression block 9 and a compression PVC pipe elastic member 10, the lower end of the connecting rod 8 is fixed on the conveyor belt 4, and the upper end of the connecting rod 8 is connected to the 1 / 4 circle The center of circle of the rotating compression b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com