Laminating and conveying device of paper mounting machine

A technology for conveying devices and laminating machines, which is applied in lamination devices, lamination, transportation and packaging, etc. It can solve problems affecting paper transmission efficiency, limited use of laminating machine equipment, and failure of normal transmission of pasted paper, etc., to achieve Ensuring operational efficiency and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

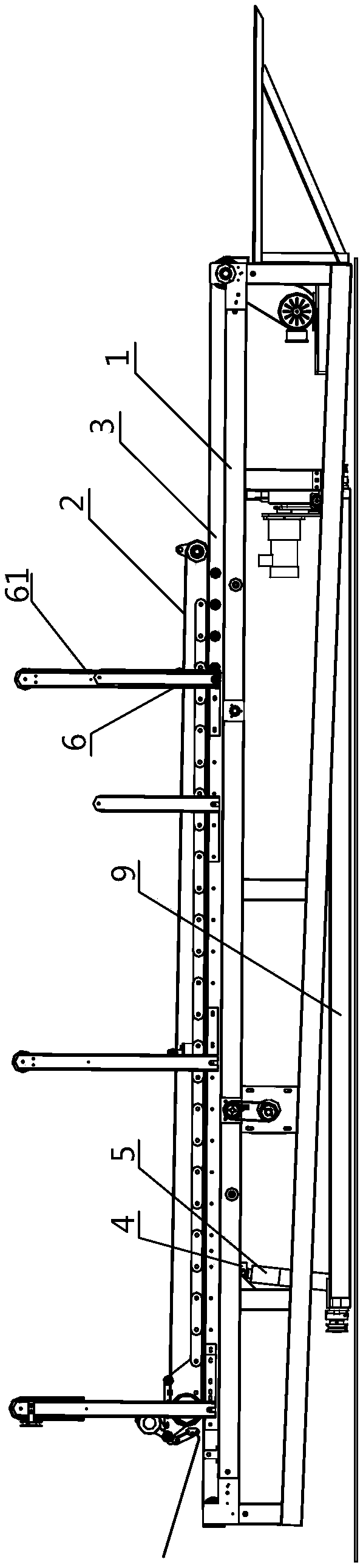

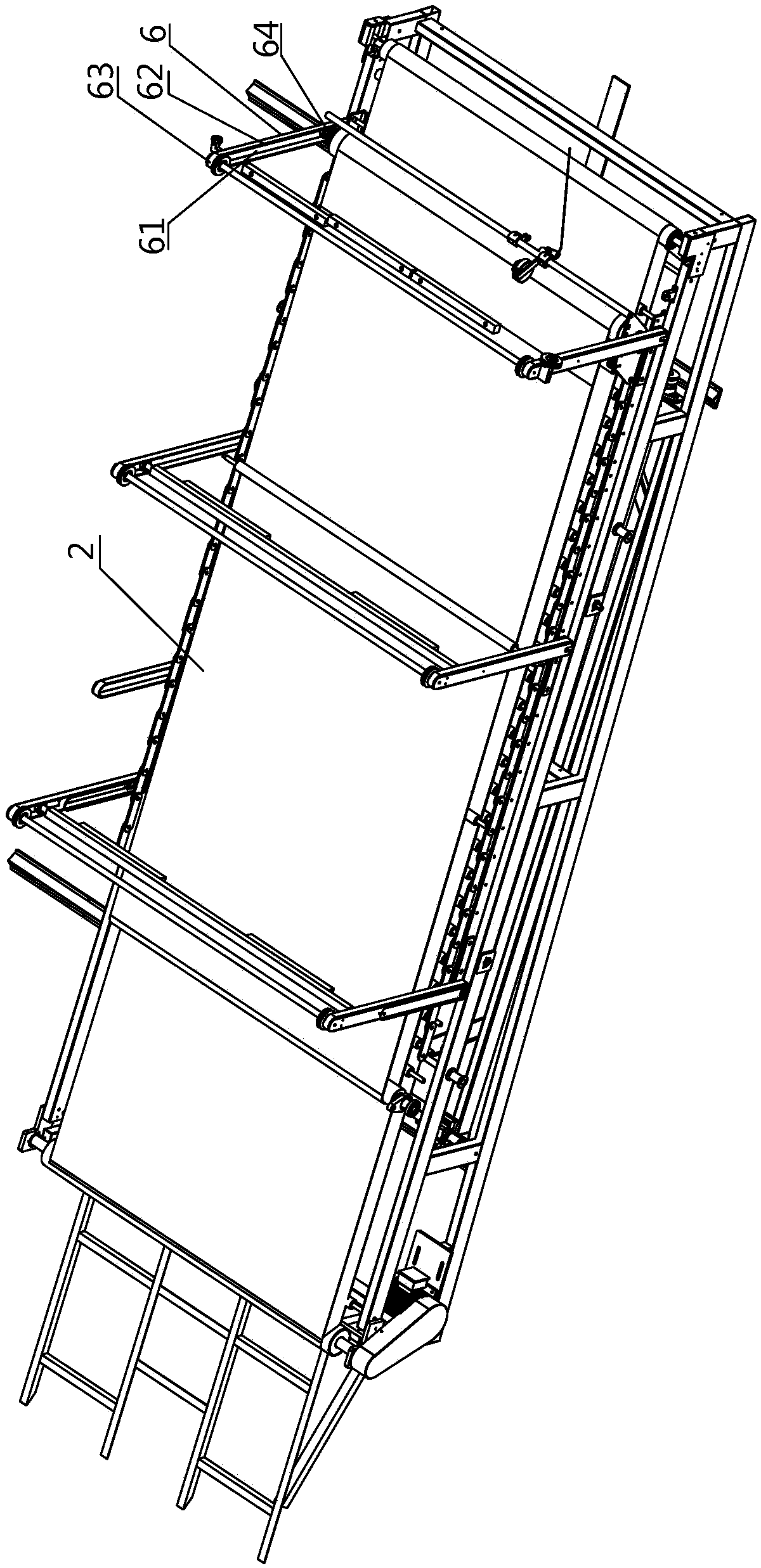

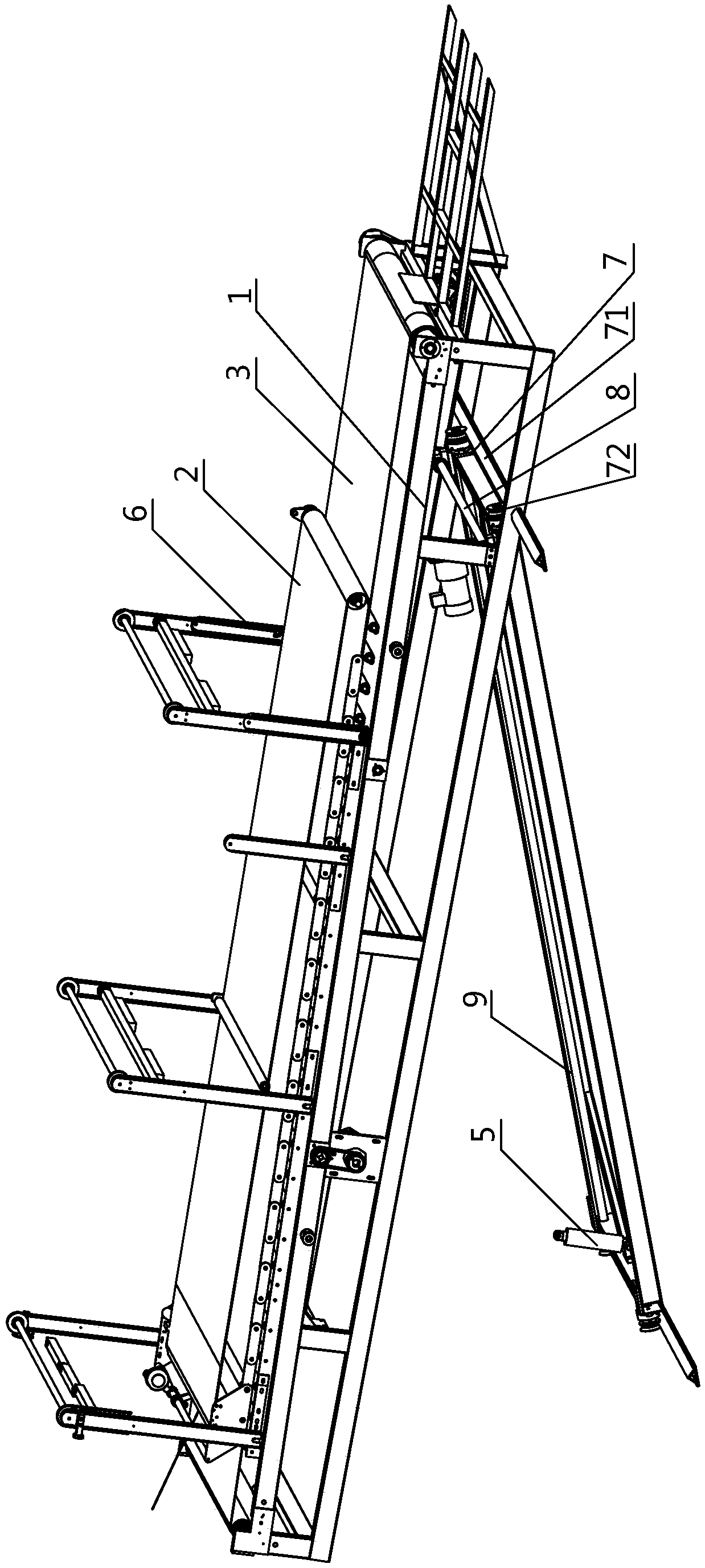

[0038] Such as Figure 1-4 As shown, the purpose of the technical means implemented in the pressing and conveying device of the laminating machine described in Embodiment 1 of the present invention is to solve the problem of the traditional laminating machine equipment transferring two sheets of paper separately through the conveying mechanism for gluing and pasting. Afterwards, because of the inability to automatically adjust the level between the next conveying device that is docked, the pasted paper after gluing and pasting cannot be conveyed normally. The frame body 1 that lowers the conveyor belt and transports the paper separately.

[0039] For the analysis of the rack body 1 structure with the above settings:

[0040] One end of the implemented frame body 1 is set as a paper feed end, and correspondingly, the other end is set as a paper output end, and the implemented lower conveyor belt 3 is fixedly arranged on the upper surface of the frame body 1, and the implemente...

Embodiment 2

[0047] Such as Figure 1-4 As shown, the technical means implemented in the pressing and conveying device of the laminating machine described in the second embodiment of the present invention are further supplements on the basis of the technical solution implemented in the first embodiment, and belong to the technical solution adopted in the first embodiment. The same idea and the same technical problem are solved. The specific implementation means are that the two ends of the implemented support frame 9 are provided with some guide wheels 72, and the guide wheels 72 at the same end are arranged on the corresponding wheel rail 71 and can be positioned on the wheel rail 71. Sliding on the top, the two ends of the implemented wheel rail 71 are fixed on the bottom beam of the frame body 1. Since the hydraulic cylinder 5 of the support frame 9 is connected with the fixed connector 4 at the bottom of the lower conveyor belt 3, when the motor drives the guide wheel 72 When sliding o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com