A receiving device for injection molding products

An injection molding and product technology, applied in the field of receiving and packaging, can solve the problems of low efficiency, time-consuming and laborious, and achieve the effect of reducing costs, fast packaging efficiency, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

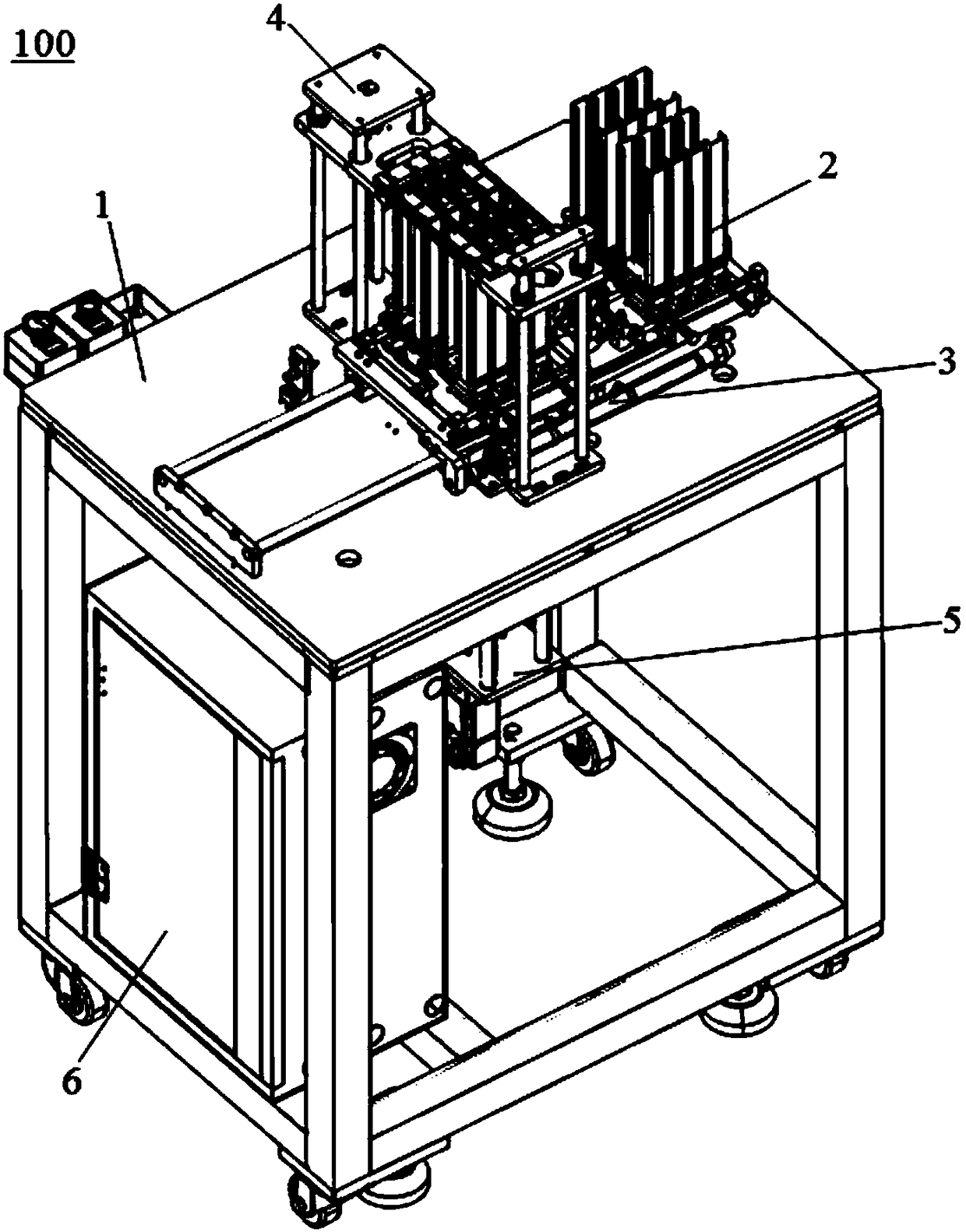

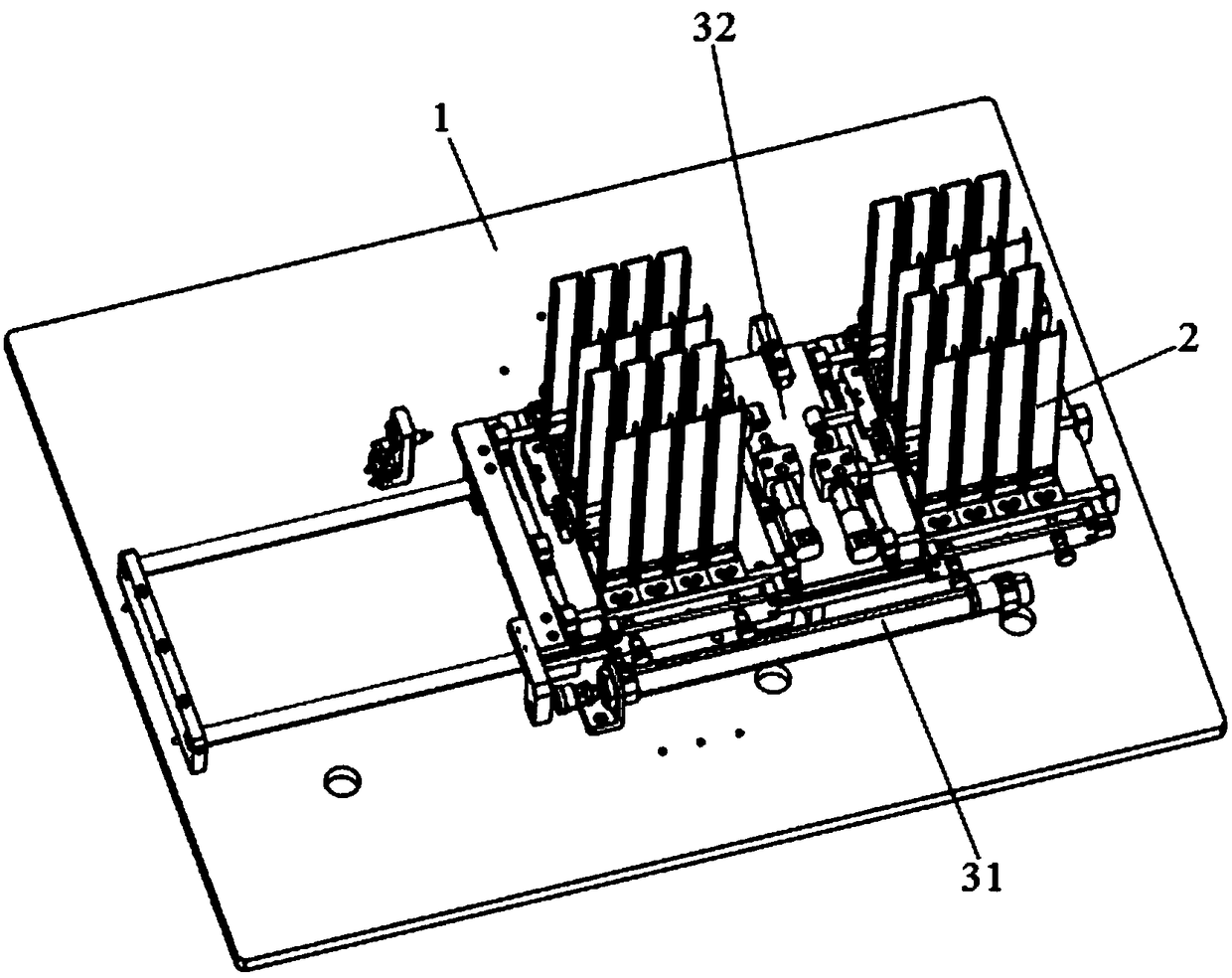

[0025] Please refer to Figure 1-Figure 5 , the present embodiment is a receiving device 100 for injection molding products, which includes a base 1, two receiving units 2 fixed on the base 1, a drive unit 3 that drives the receiving unit 2 to move left and right, The positioning and clamping device 4 clamped by the receiving unit 2, the lifting device 5 for holding the product and the electric control box 6.

[0026] The driving unit 3 includes a first air cylinder 31 fixed on the base 1 , and a first connecting plate 32 driven by the first air cylinder 31 to move left and right.

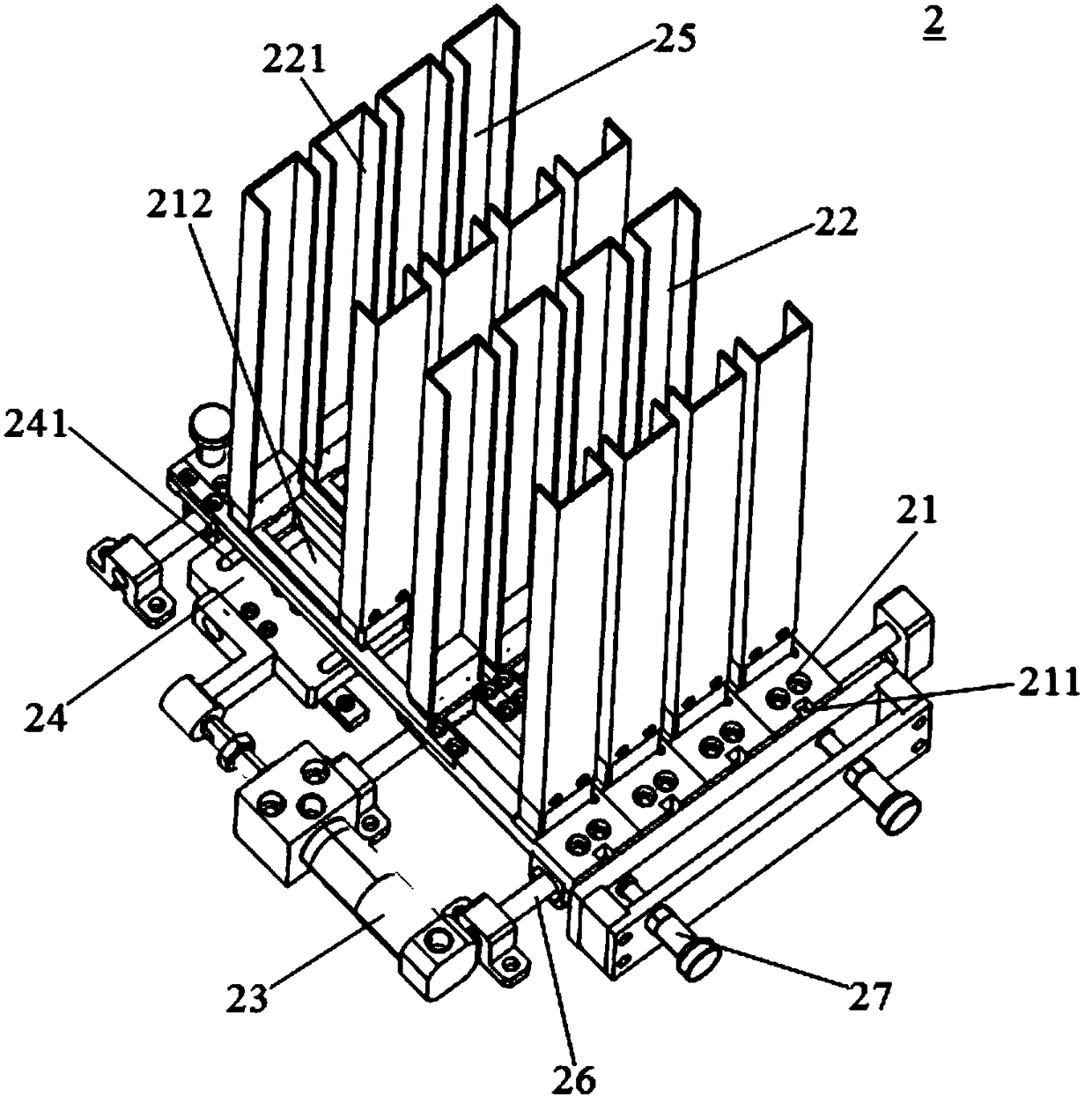

[0027] The receiving unit 2 includes four support plates 21 with adjustable left and right positions arranged on the first connecting plate 32 , the first feed bin 22 fixed on the supporting plate 21 , and the second air cylinder fixed on the first connecting plate 32 23. The second connecting plate 24 driven by the second cylinder 23 to move back and forth, and the second material bin 25 movably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com