Method for mounting ultra-large container ship crack arrest steel hatch coaming

A container ship and hatch coaming technology, which is applied to ship components, ship construction, transportation and packaging, etc., can solve the problems of high installation risk of crack arresting steel hatch coaming, affect ship construction period, and low installation accuracy, and achieve shortened The effect of the construction period, reducing the risk of damage, and reducing the risk of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] A method for the installation of crack arresting steel hatch coamings for ultra-large container ships of the present invention will be further described in detail below in conjunction with the accompanying drawings, in order to understand the application process of the method of the present invention more clearly, but it cannot be based on this To limit the protection scope of the present invention.

[0032] like Figure 1-6 As shown, the present embodiment is used for the installation method of the anti-crack steel hatch coaming of an ultra-large container ship, and the installation method includes the following steps:

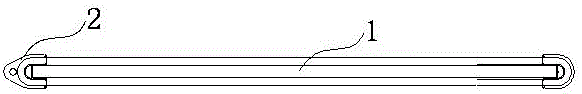

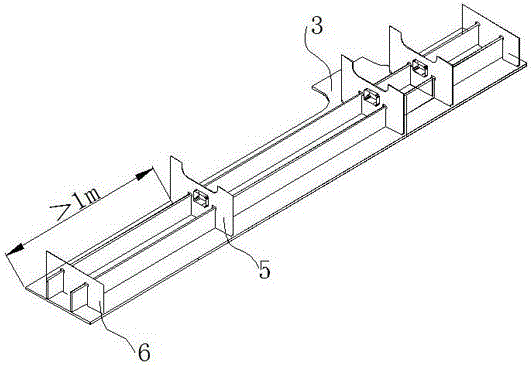

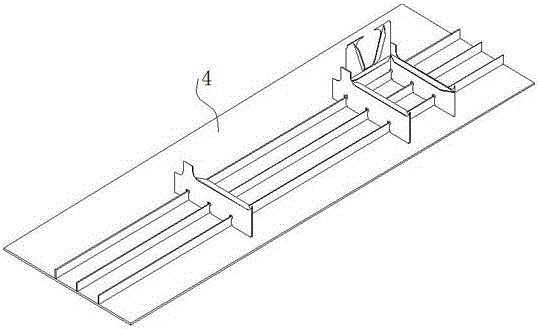

[0033] S1. The group to which the torsion box belongs is manufactured independently, and the main board 1 is assembled, and then the main deck group 3, the longitudinal wall group 4 and the outer rib 5 are assembled and welded. When the distance between the outer rib 5 and the end of the component is > 1m , on the main deck group 3, a false compartmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com