Multi-chamber fluid bags

A multi-chamber, packaging bag technology, used in packaging, transportation and packaging, containers with multiple items, etc., can solve problems such as waste, inconvenience, and spillage of seasonings, and achieve the effect of avoiding waste and facilitating extrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

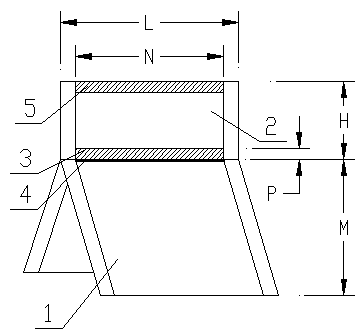

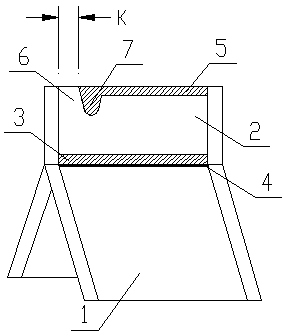

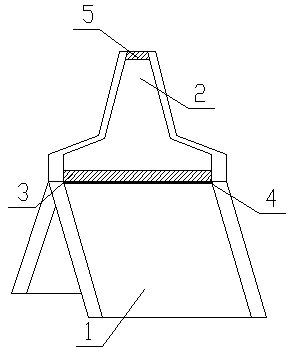

[0038] like figure 1 As shown, the multi-chamber fluid packaging bag includes a mixed bag 2 and at least two soft bag bodies 1 independent of each other, each side of the soft bag body 1 is provided with a pocket 4, and the side of the mixed bag 2 One side is provided with the sealing side 3 that connects the bag mouth 4 and the mixing bag 2 by extruding the soft bag body 1. When the soft bag body 1 is not squeezed, the sealing side 3 is in a sealed state. When the soft bag body 1 is squeezed , the fluid in the soft bag body 1 breaks through the sealing edge 3, and the sealing edge 3 is in an open state. At this time, the soft bag body 1 communicates with the mixing bag 2, and the fluid in the soft bag body 1 flows into the mixing bag 2 for mixing. The other side is provided with a sealing edge 5 for opening or sealing the mixing bag 2. The fluids in at least two mutually independent soft bags (1) are squeezed into the mixing bag (2) and then discharged after mixing. The mixin...

Embodiment 2

[0041] like figure 1As shown, the multi-chamber fluid packaging bag includes a mixed bag 2 and at least two soft bag bodies 1 independent of each other, each side of the soft bag body 1 is provided with a pocket 4, and the side of the mixed bag 2 One side is provided with the sealing side 3 that connects the bag mouth 4 and the mixing bag 2 by extruding the soft bag body 1. When the soft bag body 1 is not squeezed, the sealing side 3 is in a sealed state. When the soft bag body 1 is squeezed , the fluid in the soft bag body 1 breaks through the sealing edge 3, and the sealing edge 3 is in an open state. At this time, the soft bag body 1 communicates with the mixing bag 2, and the fluid in the soft bag body 1 flows into the mixing bag 2 for mixing. The other side is provided with a sealing edge 5 for opening or sealing the mixing bag 2. The fluids in at least two mutually independent soft bags (1) are squeezed into the mixing bag (2) and then discharged after mixing. The mixing...

Embodiment 3

[0046] like figure 1 As shown, the multi-chamber fluid packaging bag includes a mixed bag 2 and at least two soft bag bodies 1 independent of each other, each side of the soft bag body 1 is provided with a pocket 4, and the side of the mixed bag 2 One side is provided with the sealing side 3 that connects the bag mouth 4 and the mixing bag 2 by extruding the soft bag body 1. When the soft bag body 1 is not squeezed, the sealing side 3 is in a sealed state. When the soft bag body 1 is squeezed , the fluid in the soft bag body 1 breaks through the sealing edge 3, and the sealing edge 3 is in an open state. At this time, the soft bag body 1 communicates with the mixing bag 2, and the fluid in the soft bag body 1 flows into the mixing bag 2 for mixing. The other side is provided with a sealing edge 5 for opening or sealing the mixing bag 2. The fluids in at least two mutually independent soft bags (1) are squeezed into the mixing bag (2) and then discharged after mixing. The mixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com