Vibration conveyor

A technology of vibration conveying and vibrator, which is applied in the direction of vibrating conveyor, conveyor, transportation and packaging, etc. It can solve problems such as unsmoothness, affecting work efficiency, uneven transportation, etc., and achieves the effect of preventing material blockage and ensuring smooth feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

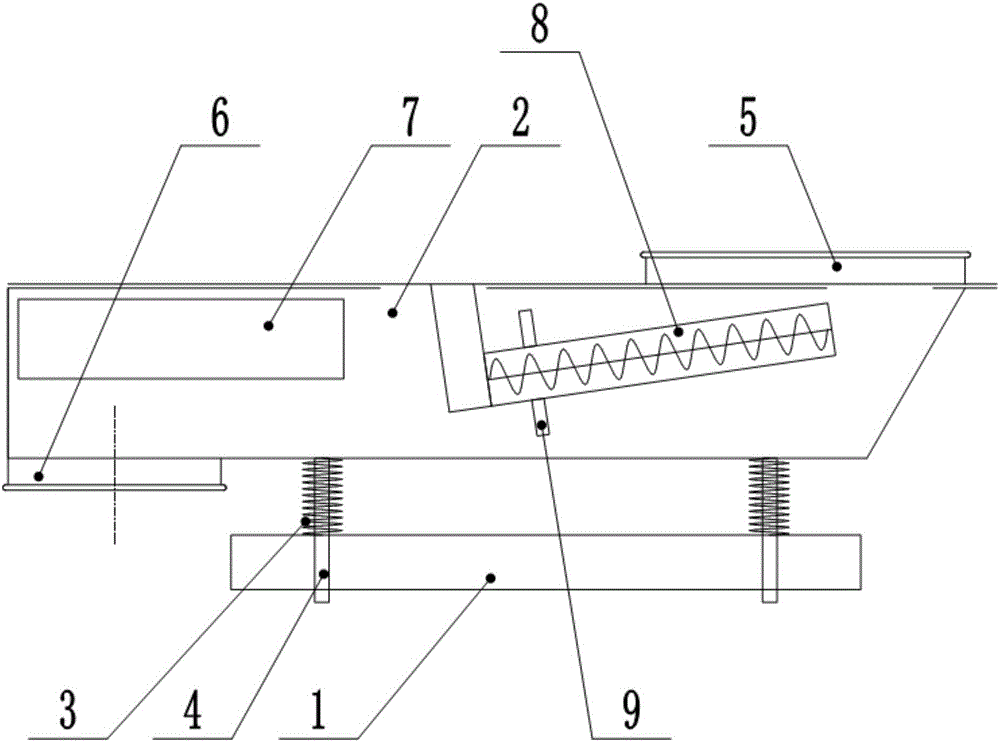

[0012] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0013] Such as figure 1 As shown, the vibrating conveyor of this embodiment includes a delivery channel 2 installed horizontally or obliquely on the base 1, a guide rod 4 with a spring 3 is installed between the delivery channel 2 and the base 1, and one end of the delivery channel 2 is an inlet The feed port 5 has a discharge port 6 at the other end, and a vibrator 7 is built in the conveying channel 2 near the discharge port 6, and a screw conveying shaft 8 inclined to be installed between the feed port 5 and the discharge port 6 is installed.

[0014] Further, in order to further improve the conveying smoothness, the outer wall of the lower end of the screw conveying shaft 8 is provided with a stirring shaft 9 .

[0015] The above examples are preferred implementations of the present invention, and are only used to illustrate the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com