A wolf tooth straw forming machine

A molding machine and wolf-tooth technology, which is applied in the direction of material molding presses, presses, mechanical equipment, etc., can solve the problem of unstable power output of power transmission devices, poor sealing effect of dust rings, and service life of wear-resistant parts. Short and other problems, to achieve the effect of beautiful molding, preventing accumulated material blockage, and solving easy boring machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

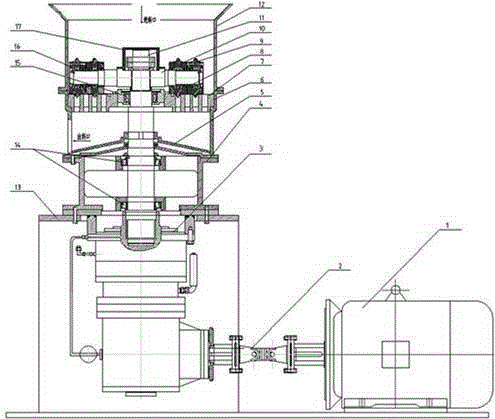

[0028] as attached Figure 1-3 As shown, the present invention provides a wolf tooth straw molding machine, which includes a feeding device, a power transmission device, a molding device and a discharge device, the power transmission device provides power for the molding device, and the straw enters the molding device through the feeding device After being formed in the forming device, it is formed into a round rod by the discharging device and then discharged.

[0029] Wherein, the feed device is a feed bin 12, the upper end of the feed bin 12 is a funnel-shaped feed inlet, and the lower end of the feed bin 12 is cylindrical;

[0030] The power transmission device of the wolf tooth straw forming machine is mainly composed of the motor 1 and the planetary reducer 3 through the universal coupling 2. The power of the motor 1 is 75KW, the input speed of the motor 1 is 1500r / min, and the planetary reducer 3 The model is JGCX75-00, the output shaft is in the form of internal splin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com