A steam cleaning device for mixing tank of sintering machine

A cleaning device and mixing technology, applied in descaling devices, cleaning methods and utensils, cleaning methods using liquids, etc., can solve problems such as clogging, achieve good results, reduce excess wet belts, and improve sintered air permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

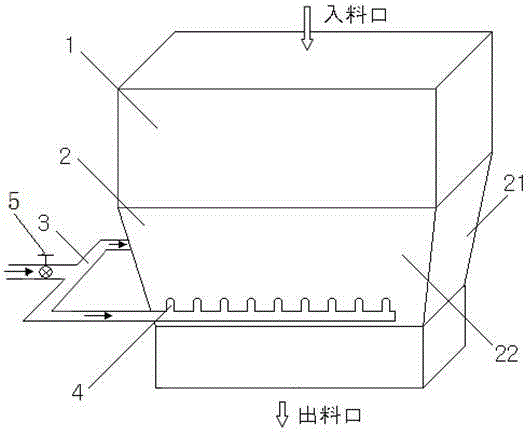

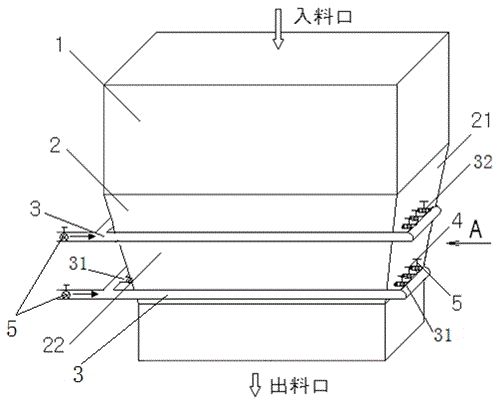

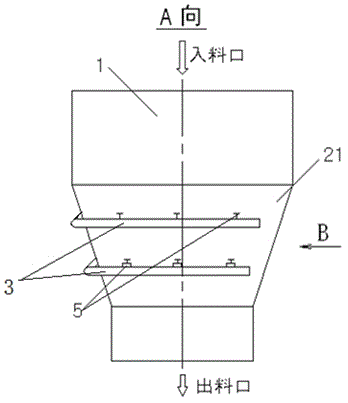

[0020] Embodiment: A steam cleaning device for the mixing tank of a sintering machine. Above the mixing tank 1 is a shuttle distributor that continuously feeds materials to the top of the mixing tank 1. Below it is the inclined bucket tank 2. The feeder discharges the mixed material from the outlet to the sintering machine trolley. Such as figure 2 , image 3 , the inclined bucket groove 2 below the mixing tank 1 is equipped with two upper and lower steam pipes 3 respectively, and the upper and lower steam pipes 3 are respectively equipped with three upper jets in the direction of the narrow inclined side wall 21. pipe 32 and three lower nozzle pipes 31. The upper and lower rows of spray pipes 32 and 31 are all connected to the steam nozzle 4 through the steam gate valve 5 . Such as Figure 4 , the lower nozzle pipe 31 is installed horizontally, and the upper nozzle pipe 32 is installed at an angle of 0° or 60° downward to the horizontal line, preferably at an angle of 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com