Roller shaft device for machining steel belt

A technology of rollers and steel belts, which is applied in the field of steel belt processing roller devices, can solve problems such as easy slipping, and achieve the effects of enhancing safety, reducing the probability of slipping, and facilitating disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

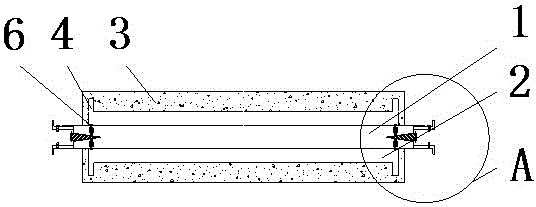

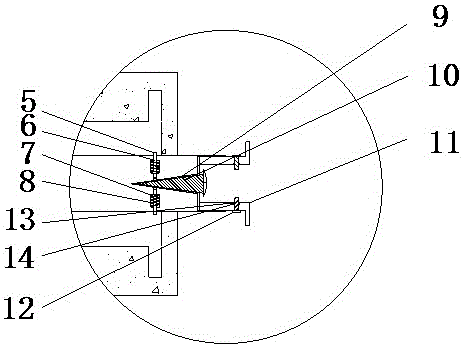

[0029] see figure 1 with figure 2 , the whole device can be put into the corresponding position, and the device can be locked by the protruding structure of the connecting ring 11, and the nut 14 can also play a role of clamping. At this time, the external steel belt rotates to drive the whole device to rotate.

Embodiment 2

[0031] see figure 1 with figure 2 , the output shaft of the corresponding power source can be inserted into the inside of the connection block 11, and the nut 14 is pressed down to fix the output shaft. This is the external power to drive the roller shaft device to rotate so as to drive the steel belt.

[0032] When in use, the steel belt is placed outside the pressure-bearing layer 3, the pressure-bearing layer 3 is squeezed, and at the same time the steel belt moves to drive the entire device to rotate.

[0033] To sum up, the steel strip processing roller device, by setting the limit ring 4, can make the pressure-bearing layer 3 be better fixed after receiving pressure, reduce the probability of slippage, and enhance safety. The groove 5 and the connecting rod 6 can use the pressure of the screw 10 to stably connect the roller shaft 1 to the roller 2 without slipping off, and can be easily disassembled, and the connection block 11 is provided to better meet various needs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com