Middle beam reinforcing structure for rail wagon and wagon frame

A technology for strengthening the structure of railway wagons, which is applied to railway car body parts, wagons, and underframes. The effect of strength and convenient maintenance work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

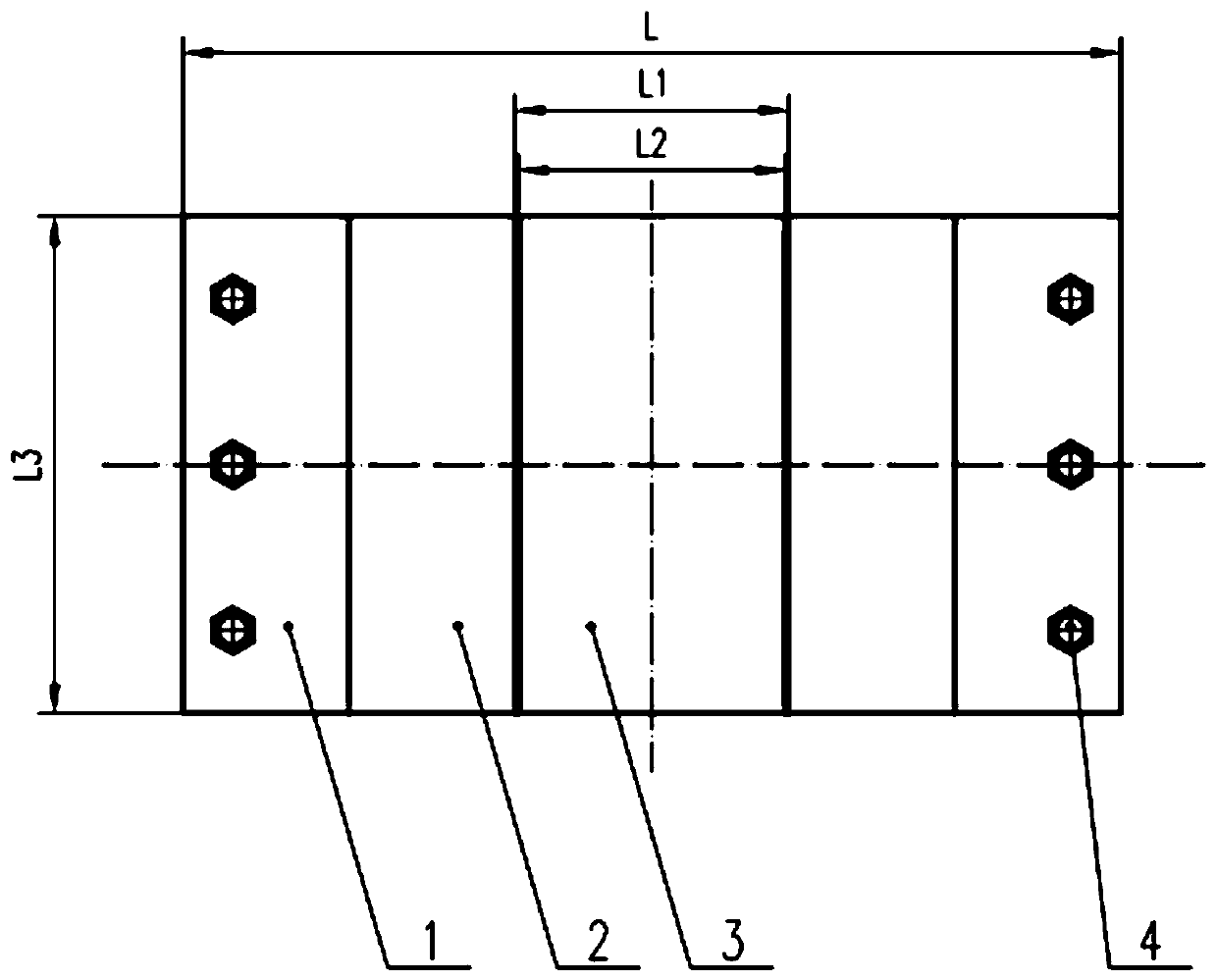

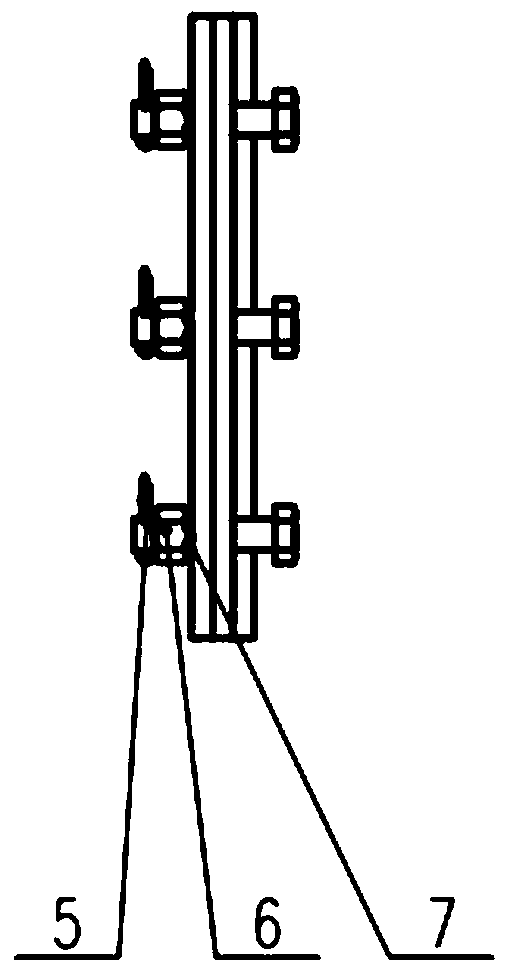

[0035] In a typical implementation of the present invention, a middle beam reinforcement structure for railway wagons, refer to the same figure 2 and image 3 As shown, including the bottom plate 2, the reinforcing plate 3 and the bottom plate 2 are welded on one side of the bottom plate 2, the reinforcing plate 3 and the bottom plate 2 are arranged concentrically, the adjusting backing plate 1 is installed on both sides of the bottom plate 2, and the adjusting backing plate 1 and the bottom plate 2 have a through hole, the through hole is a threaded hole, through the locking piece to realize the connection between the adjustment backing plate 1 and the bottom plate 2, and realize the connection with the middle sill, and install the whole reinforcement structure on the lower plane of the lower flange of the middle sill , and insert the reinforcement plate 3 into the hollow of the lower flange of the center sill, and insert the reinforcement plate 3 into the hollow of the lowe...

Embodiment 2

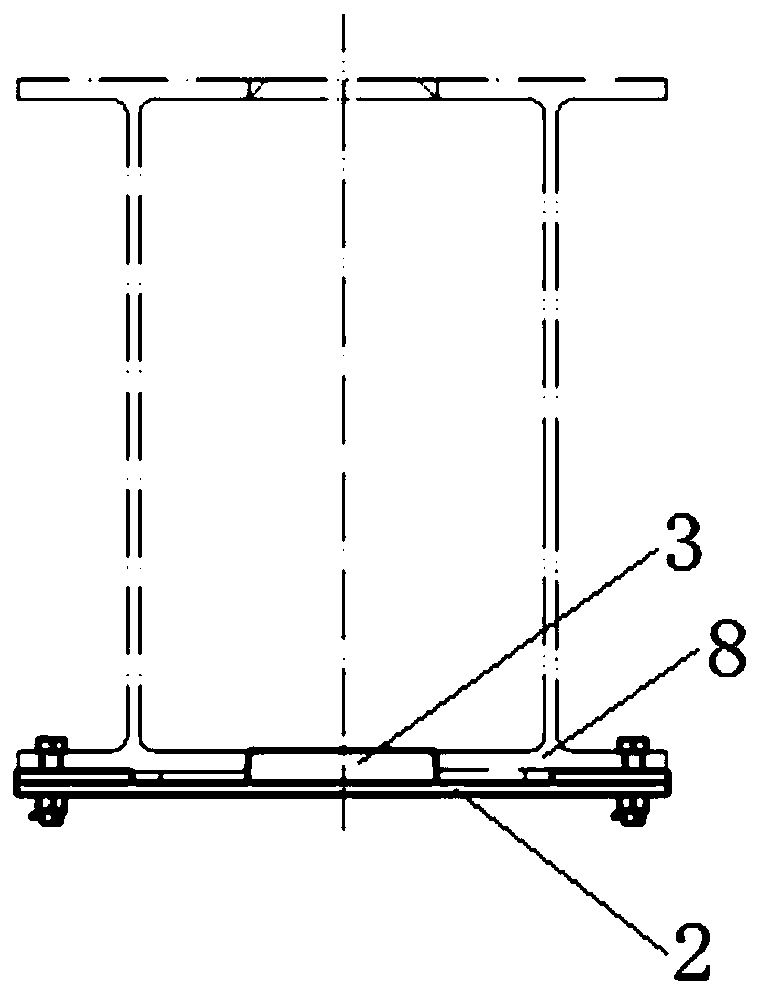

[0043] This embodiment discloses a frame for railway wagons, refer to figure 1 As shown, it includes a middle sill reinforcement structure for a railway freight car described in Embodiment 1, which is installed on the lower flange 8 of the middle sill of a railway freight car.

[0044] The middle sill reinforcement structure for railway freight cars is installed on the lower plane of the lower flange 8 of the middle sill, which not only plays a reinforcing role but also plays an anti-loosening effect. It can be installed in the inner cavity of the center sill to ensure the assembly efficiency of railway wagons. At the same time, it can effectively enhance the strength of the center sill and prevent the brake components in the inner cavity of the center sill from falling off the rails, causing adverse consequences; when maintenance is required, Because the reinforced structure is detachably connected with the center beam, it also greatly facilitates the inspection and maintenan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com