Automobile lifting machine table top and auxiliary device for automobile maintaining and repairing

A technology for lifts and tabletops, which is applied in the direction of lifting frames, lifting devices, etc., can solve problems such as potential safety hazards, and achieve the effects of small potential safety hazards, convenient and quick docking, and convenient manufacturing and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

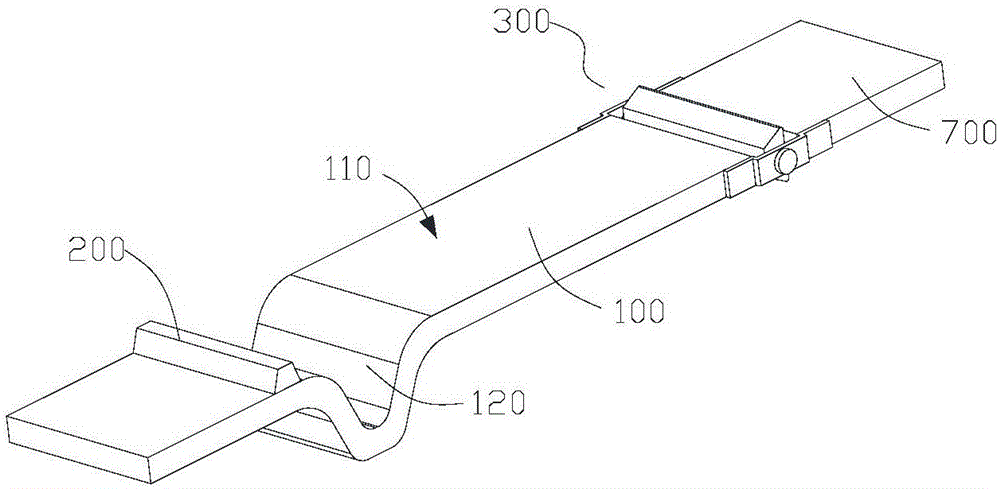

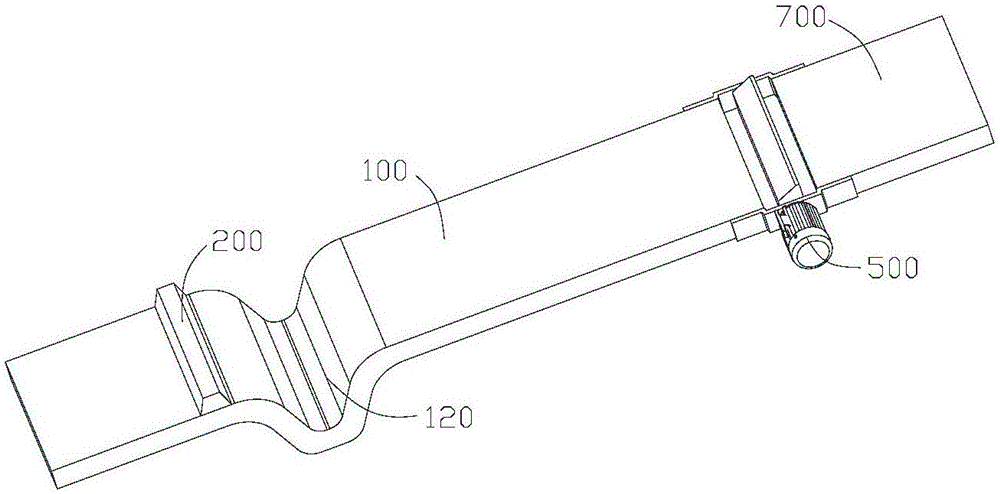

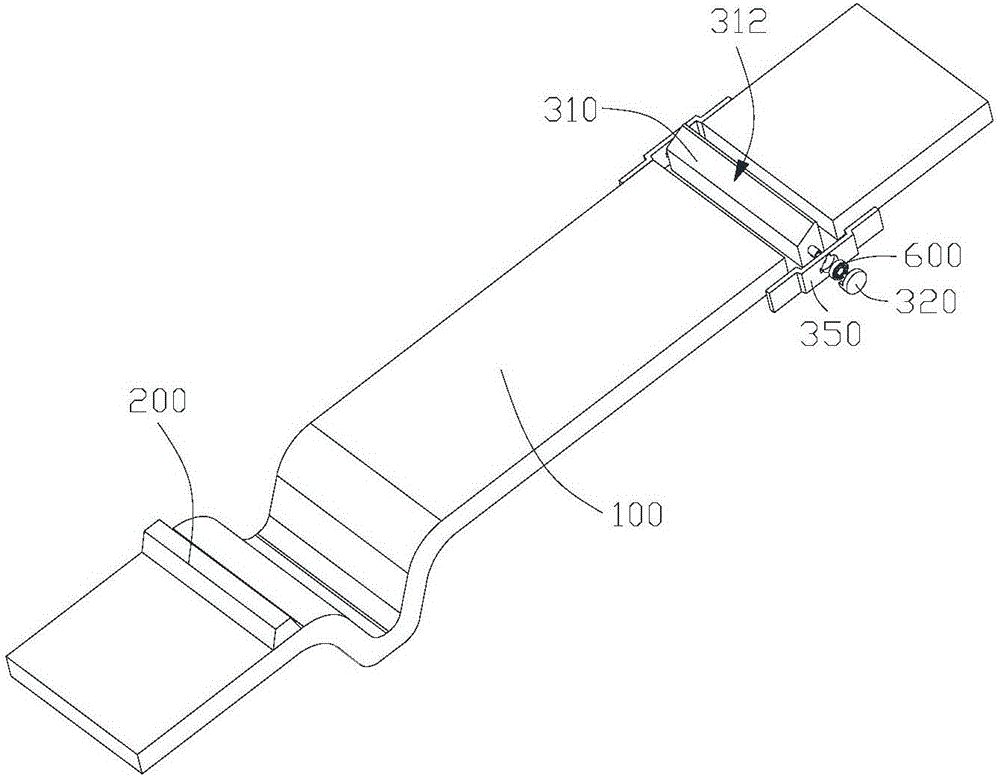

Image

Examples

Embodiment Construction

[0036]Most of the lift tables on the existing market are made of patterned plates, and some lift tables are made of rubber plates on bare plates or patterned plates, and some even use bare plates directly. If the brake system of the car fails or malfunctions , even a rubber plate with high frictional resistance is difficult to stop the inertial movement of the car, and there are potential safety hazards; there are also auxiliary equipment for automobile maintenance that use baffles to block the three sides of the table, the structure is relatively complicated, and the table top needs to be integrated , the processing cost is high. Regardless of whether there is a physical barrier or no physical barrier, the driver cannot comfortably and clearly feel whether the vehicle has driven to a suitable inspection position, so there are certain safety hazards during the lifting process.

[0037] In view of this, the designer of the present invention has designed a car lift table and aux...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com