Dye kettle for supercritical CO2 waterless dyeing, and waterless dyeing method

An anhydrous dyeing and supercritical technology, which is applied in the processing of textile material containers and the configuration of textile material equipment, can solve the problems of dyeing, unevenness, uneven dyeing of fabrics, etc., achieve accurate dye amount, reduce color, and guarantee quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

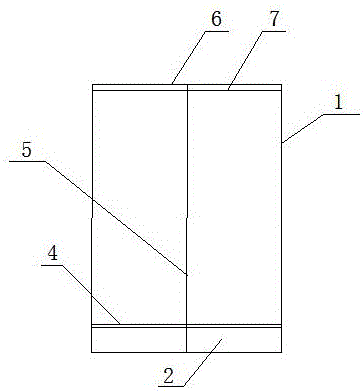

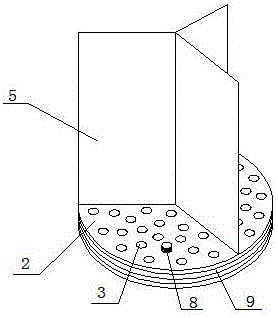

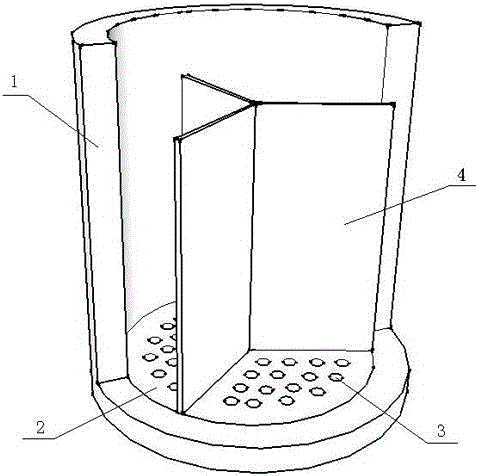

[0026] see Figure 1-Figure 3 , the present invention is a supercritical CO 2 An embodiment of a dye kettle for anhydrous dyeing, including a dye kettle body and a dye cartridge in the dye kettle body, the dye cartridge includes a cylindrical shell 1 and a chassis 2, and the chassis 2 is arranged at the lower end of the cylindrical shell. Distributing holes 3 are evenly distributed on the chassis 2, and at least three dye separation channels 5 are vertically arranged on the chassis 2, and the dye separation channels 5 are enclosed by a partition and a cylindrical shell 1 vertically fixed on the chassis 2, The bottom in the dye tube is positioned at the top of the chassis 2 to set a dye net 4 for placing the dye, and the dye is placed on the dye net 4, so that CO 2 The airflow can pass through the dye net 4 smoothly, and can make the dye and CO 2 Airflow full exposure. A filter membrane 7 is arranged on the top of the dye cartridge, and a protective net 6 is set above the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com