Supercritical CO2 waterless staining dye pot and waterless staining method

An anhydrous dyeing and supercritical technology, applied in the processing of textile materials, processing textile material containers, processing textile material equipment configuration, etc., can solve the problems of different solubility and high solubility, and achieve accurate analysis of experimental data and dissolution Appropriate ratio, the effect of increasing the amount of dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

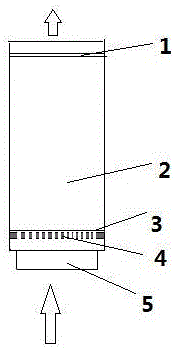

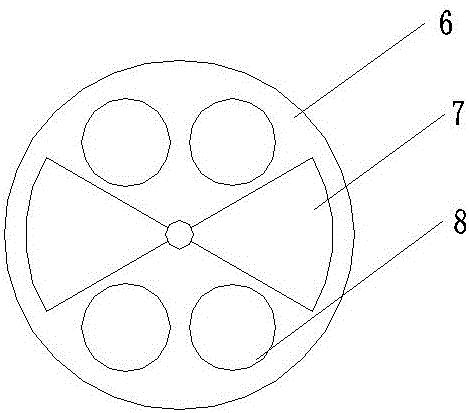

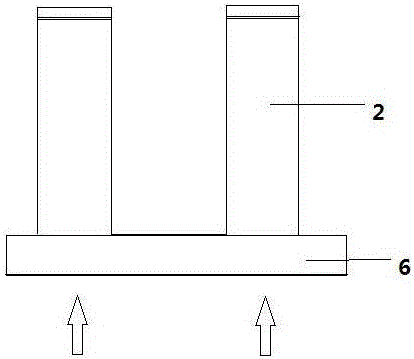

[0033] see figure 1 , figure 2 , the present invention utilizes the above-mentioned supercritical CO 2 The specific embodiment of the method for anhydrous dyeing dye still, comprises the following steps:

[0034] (1) Firstly, place the weighed various dyes used for supercritical anhydrous dyeing on the metal mesh layer 4 in different dye cartridges 2, and fix the dye cartridges 2 to the chassis 6. If the chassis 6 The shunt hole 8 that is not available on the top is covered with the rotating mask 7;

[0035] (2) CO heated to a supercritical state under pressure 2 It enters the chassis 6 from the diversion pipeline, and is divided into multiple bundles, which are used to dissolve different kinds of dyes, supercritical CO 2 After passing through each split hole, it reaches each dye cartridge 2 with different dyes, and the air flow passes through the metal mesh layer 4 smoothly, so that the dye is fully in contact with the air flow, and only the dye in the dissolved state ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com