Device capable of monitoring concrete pouring speed and height of cast-in-place concrete pile

A technology of pouring speed and concrete, applied in construction, infrastructure engineering, etc., can solve problems such as inaccuracy and trouble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

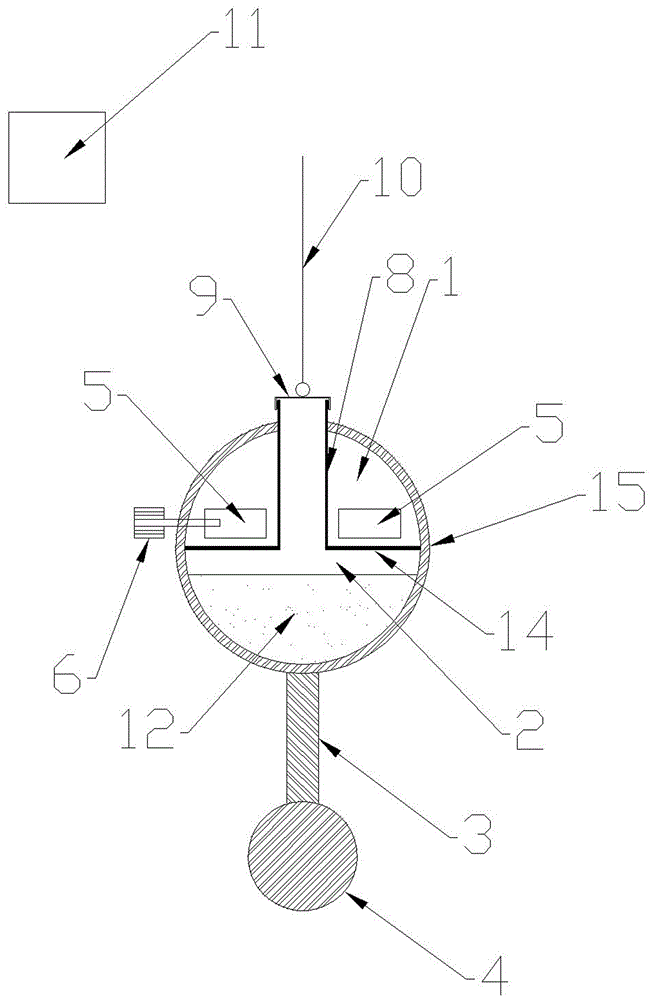

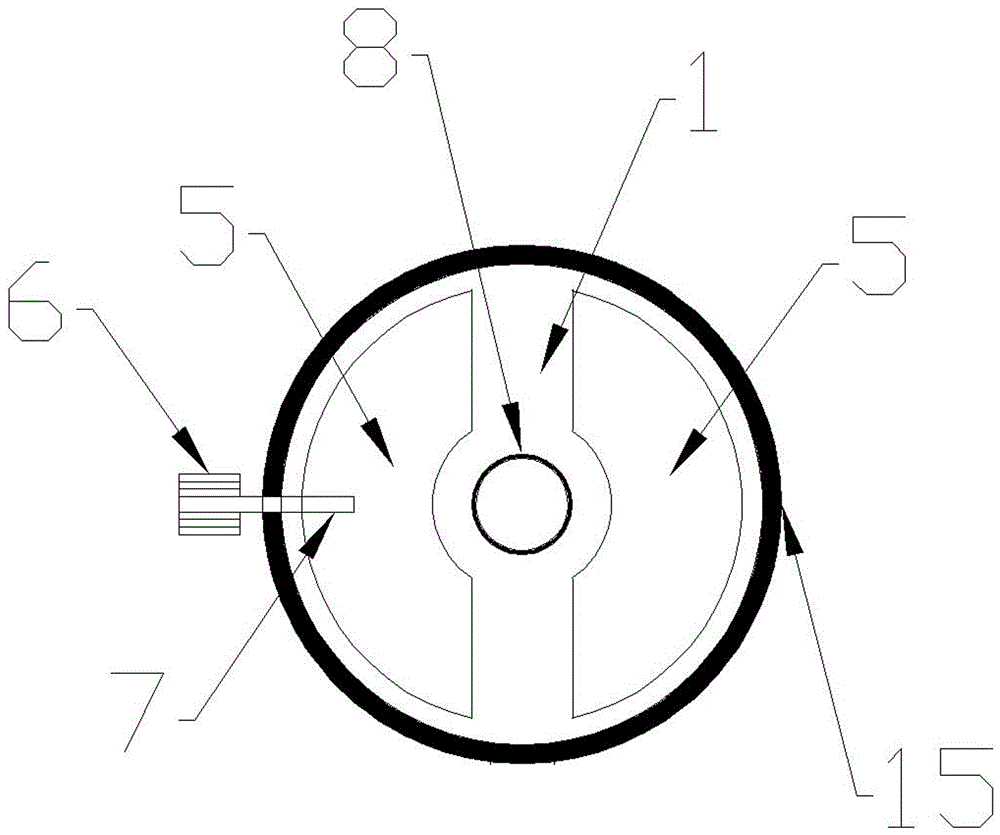

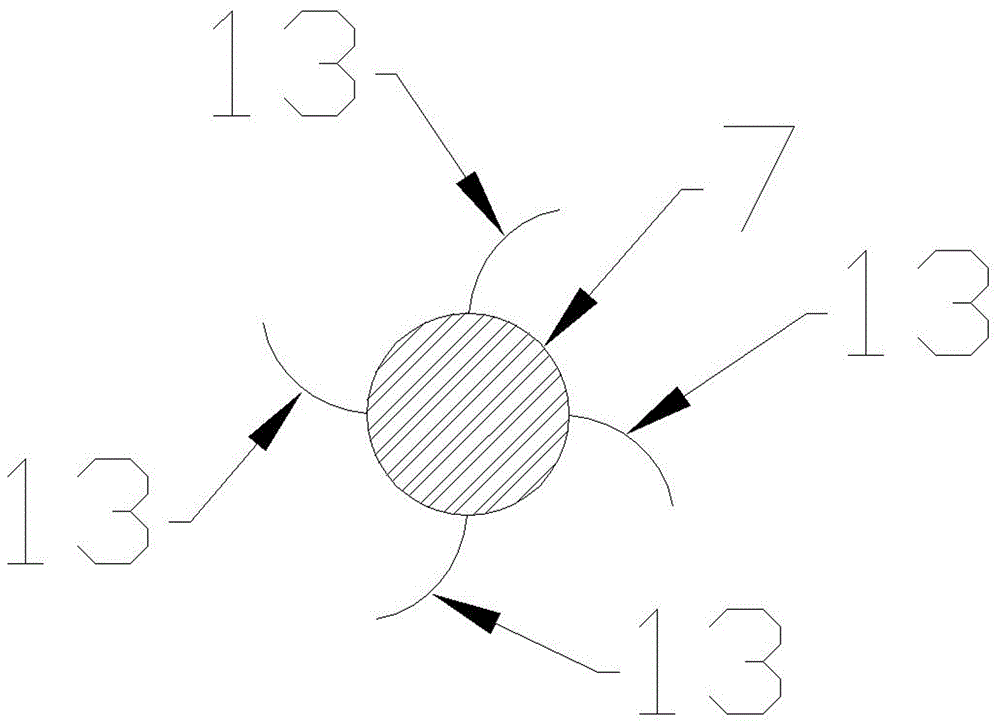

[0008] The content of the invention has described the specific embodiment of the present invention in detail, need to explain as follows: See figure 1 , figure 2 , the mechanical mouse component 5 should be arranged in the upper ball chamber 1 as symmetrically as possible, so that the center of gravity of the floating ball 15 is on the central axis to ensure the left and right balance of the floating ball 15; the shaft 7 of the impeller 6 passes through the hole of the upper ball chamber 1 The sealing ring should be designed to ensure that the mud will not enter the upper ball chamber 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com