Simulation device and method for monitoring integrity of hydrate stratum cement sheath through DAS

A simulation device and cement sheath technology, applied in teaching models, instruments, buildings, etc., can solve problems such as cement sheath integrity damage, cement sheath integrity failure, well kick, blowout, etc., and achieve strong anti-corrosion and anti-electromagnetic interference capabilities Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings to more clearly understand the object, characteristics and advantages of the present invention. It should be understood that the embodiments shown in the drawings are not limited to the scope of the invention, but intended to illustrate the spiritual spirit of the technical solution of the present invention.

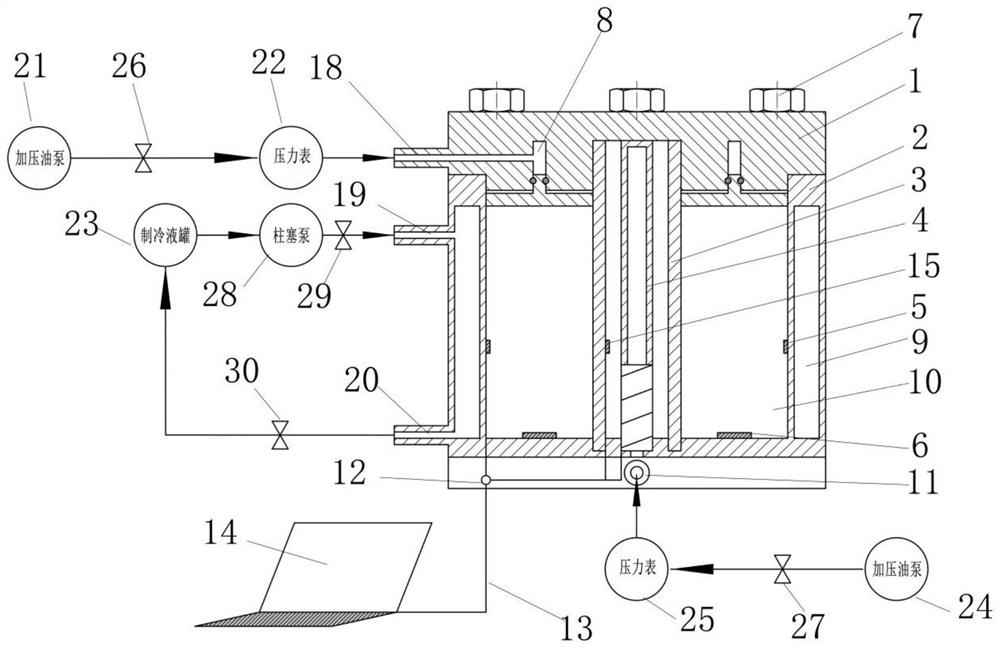

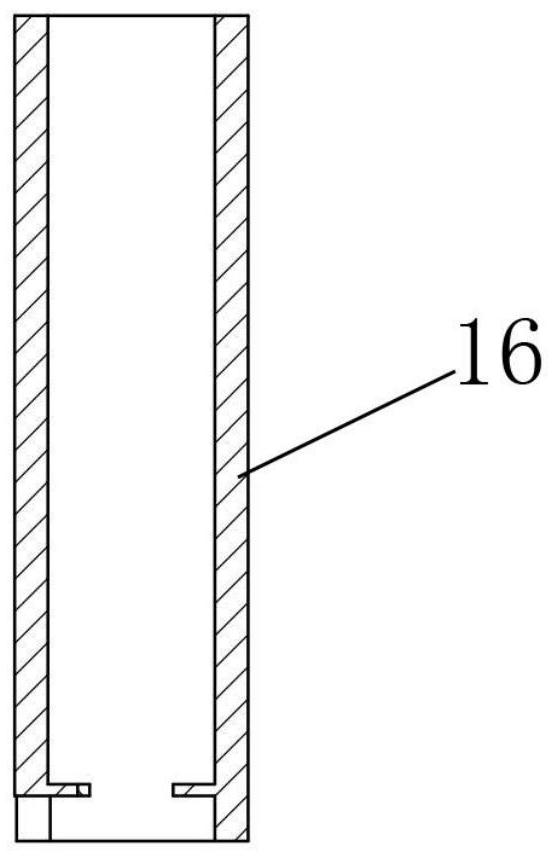

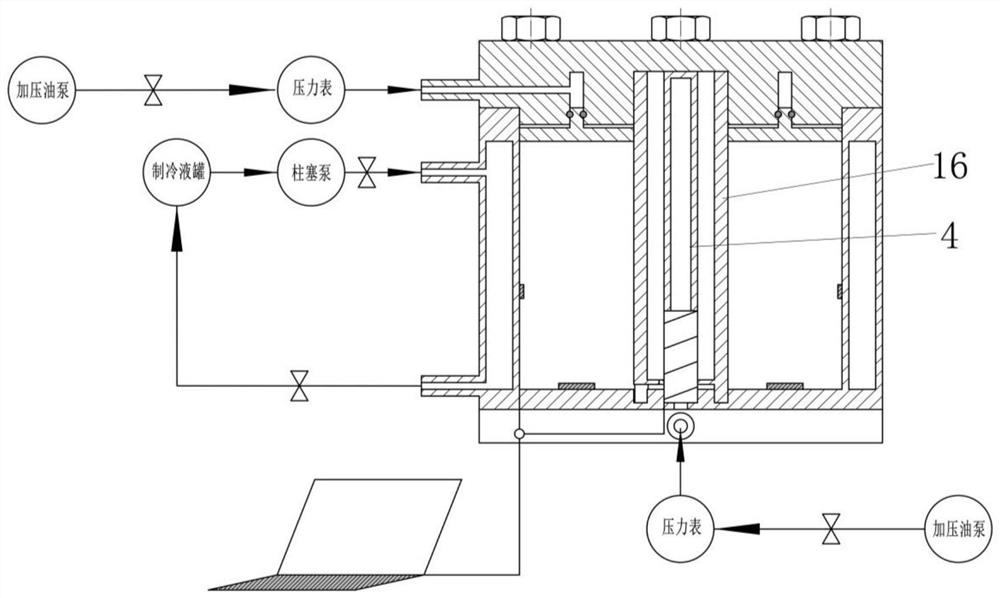

[0035]The present invention provides a simulation device for DAS monitoring hydrate formation cement ring integrity, including: analog formation system, analog wellbore system, monitoring system, pressure control system and low temperature control system; the simulated formation system includes a kettle and a kettle body The kettle and the kettle body are connected by a block bolt; the kettle cover includes a top and bottom, and an annular hydraulic oil chamber is provided, and the bottom bonds of the knee cover have a ring The annular proje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com