Positioning mechanism for tower footing and positioning construction method for tower footing

A positioning mechanism and tower base technology, applied in infrastructure engineering, construction, etc., can solve the coaxiality and levelness deviation of anchor bolt spacing, the size, shape and center position of the center connection line of the four tower bases. Deviation, anchor bolts cannot be arranged squarely, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

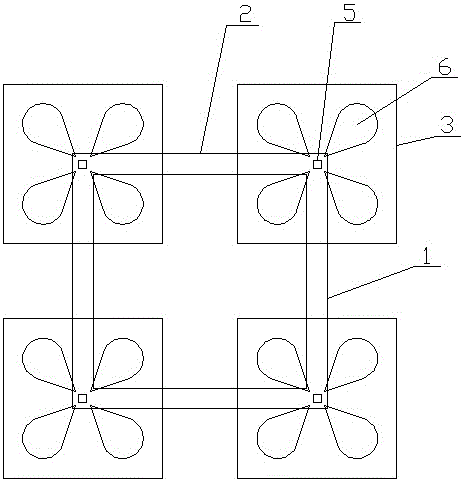

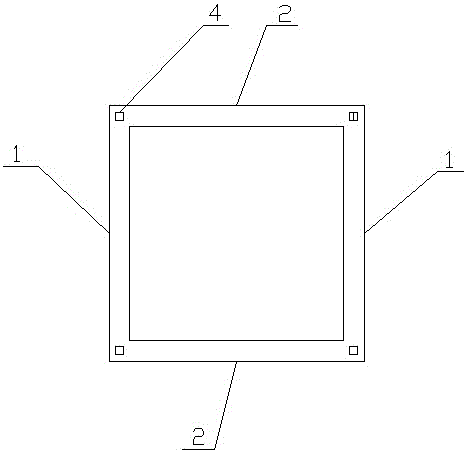

[0030] Such as Figure 1 to Figure 3 As shown, a tower base positioning mechanism of the present invention includes a horizontally arranged rectangular positioning frame. The rectangle where the rectangular positioning frame is located corresponds to the rectangle formed by the center lines of the four tower bases of the transmission tower. The rectangular positioning frame consists of two Two parallel longitudinal positioning rods 1 and two parallel horizontal positioning rods 2 are connected, and the four intersections of the rectangular positioning frames are respectively provided with horizontal positioning plates 3, the positioning plates 3 are square, and the four positioning plates 3 The connecting line of the center is also rectangular;

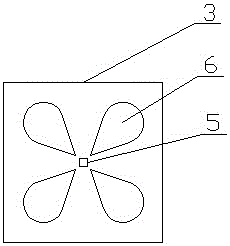

[0031] The center of each positioning plate 3 is provided with a mounting hole 5, the cross-section of the mounting hole 5 is a square, and the square where the mounting hole 5 is located is concentric with the square where the corres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com