Automobile engine oil draining device

A technology for oil and automobiles, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of new oil deterioration, old oil adhered to the engine and cannot be discharged, affecting the life of new oil, etc., to avoid deterioration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

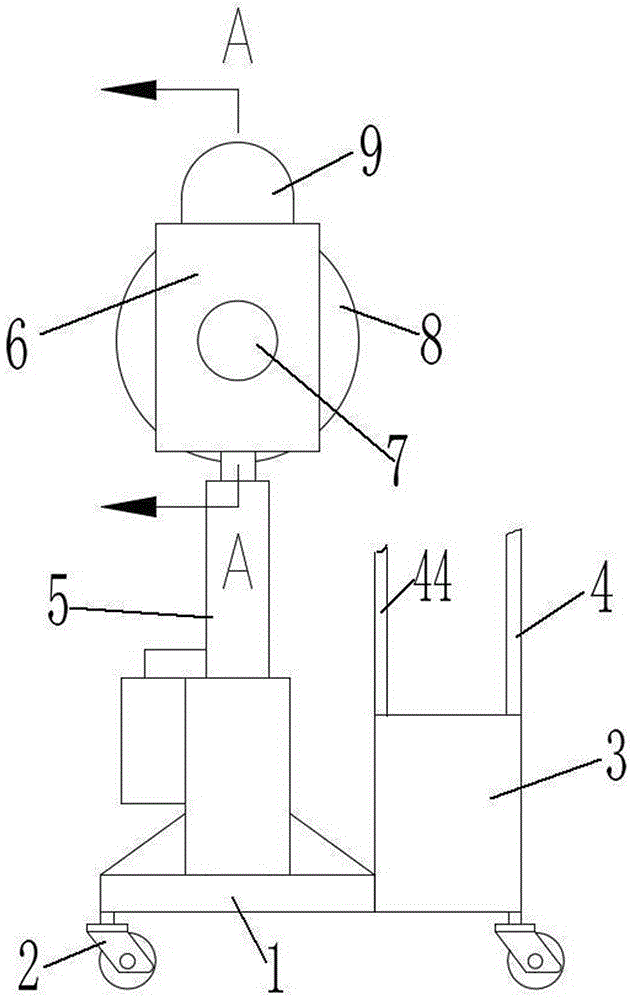

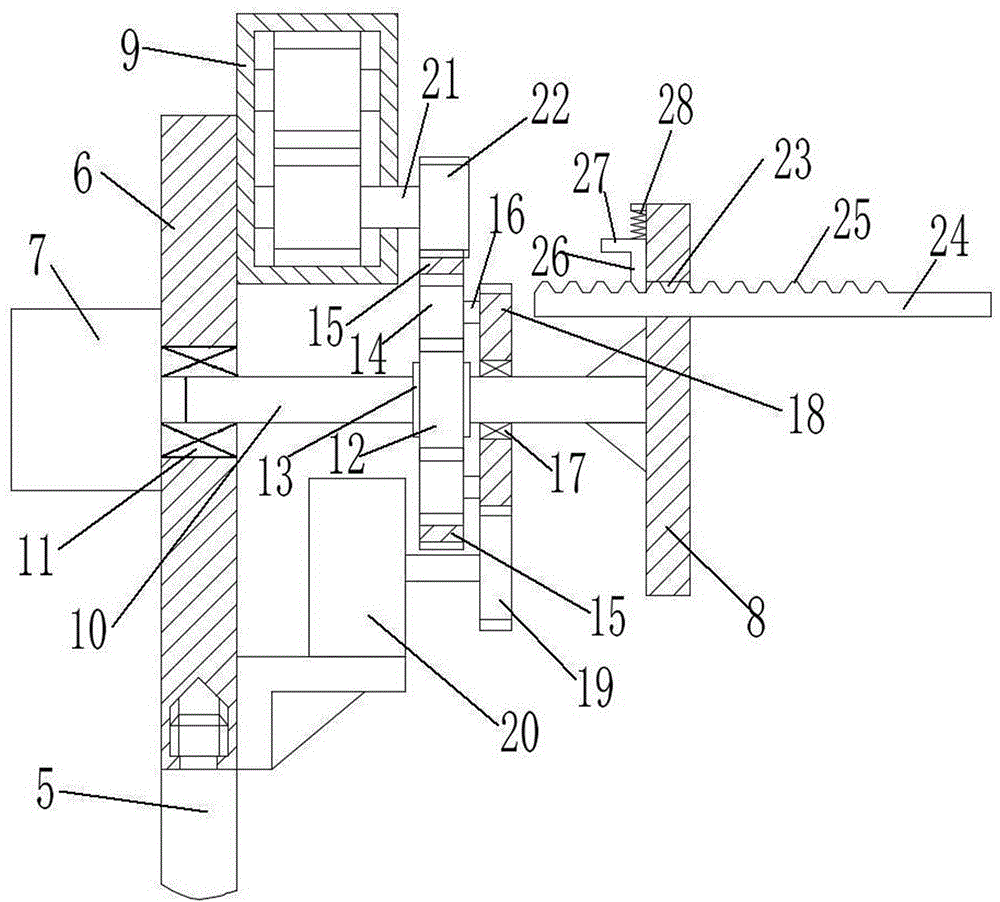

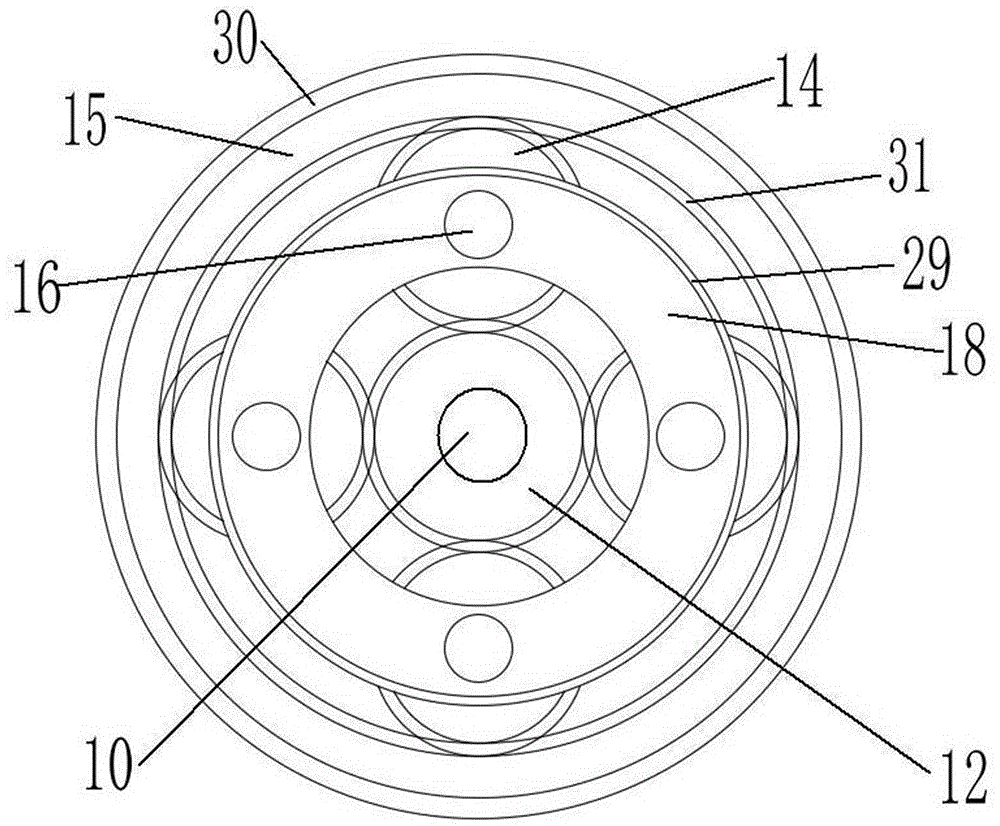

[0030] Attached below figure 1 to attach Figure 5 The present invention will be further described.

[0031] An automobile engine oil discharge device, comprising: a chassis 1; an electro-hydraulic cylinder 5 vertically installed on the chassis 1, the head end of the piston rod of the electro-hydraulic cylinder 5 is connected with a bracket 6; an oil tank 3 is installed on the chassis 1; a motor 7 , installed on the bracket 6; the rotating shaft I 10 is installed on the bracket 6 through the horizontal rotation of the bearing I 11, and the tail end of the rotating shaft I 10 is connected with the motor 7; the turntable 8 is vertically fixed on the head end of the rotating shaft I 10, The eccentric part of the turntable 8 is provided with a chute 23 horizontally; the lever 24 is horizontally slid and inserted in the chute 23 and locked and fixed by the locking device; the gear pump 9 is installed on the bracket 6, and it is driven by the gear pump drive mechanism. Drive opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com