Test soil tank for comprehensive test of working performance of road roller

A comprehensive testing, road roller technology, applied in the testing of machine/structural components, vehicle testing, measuring devices, etc., can solve the problems of time-consuming and laborious, difficult to compare the performance of compacted materials, and the composition of compacted media is not the same. achieve the effect of guaranteeing comparability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in further detail below in conjunction with accompanying drawing:

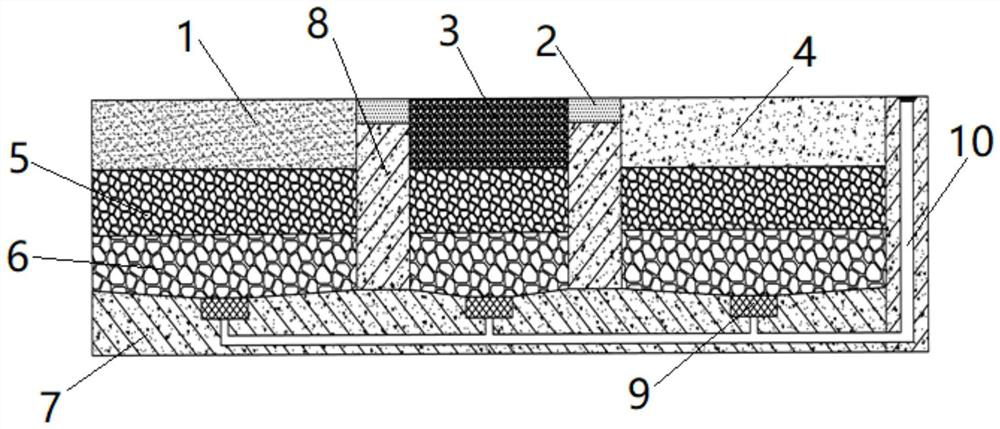

[0025] like figure 1 Shown is the test soil tank for the comprehensive test of road roller operation performance according to the present invention, including the foundation 7 .

[0026] Three sections of test areas are set on foundation 7, and an isolation area is set in the middle of each section of the test area; the three sections of test areas are respectively sand test area, graded crushed stone test area and graded soil test area, and the sand test area is paved with sand 1. Lay graded gravel 3 in the test area of graded gravel, lay graded soil 4 in the test area of graded soil, and lay other common compaction materials in each test area.

[0027] Sandy soil 1 includes particles with a particle size larger than 2mm and particles with a particle size larger than 0.075mm, the mass of particles with a particle size larger than 2mm is less than 50% of the total...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com