Core pack thrust bearing

A thrust bearing and core package technology, applied in the direction of bearings, bearing components, shafts and bearings, can solve the problems of reducing the service life of thrust bearings and uneven force on the pads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

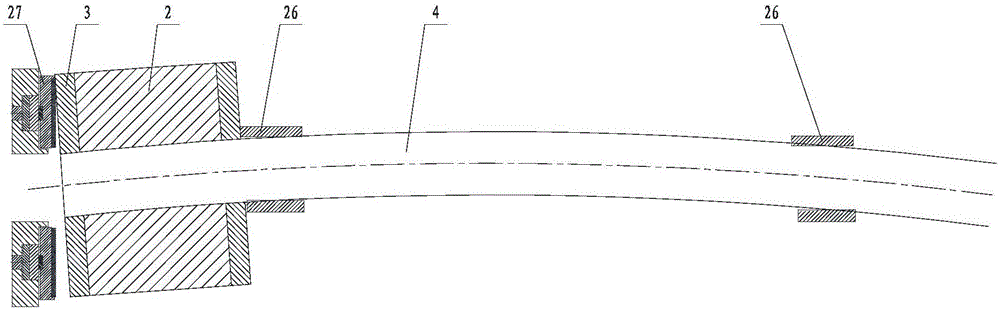

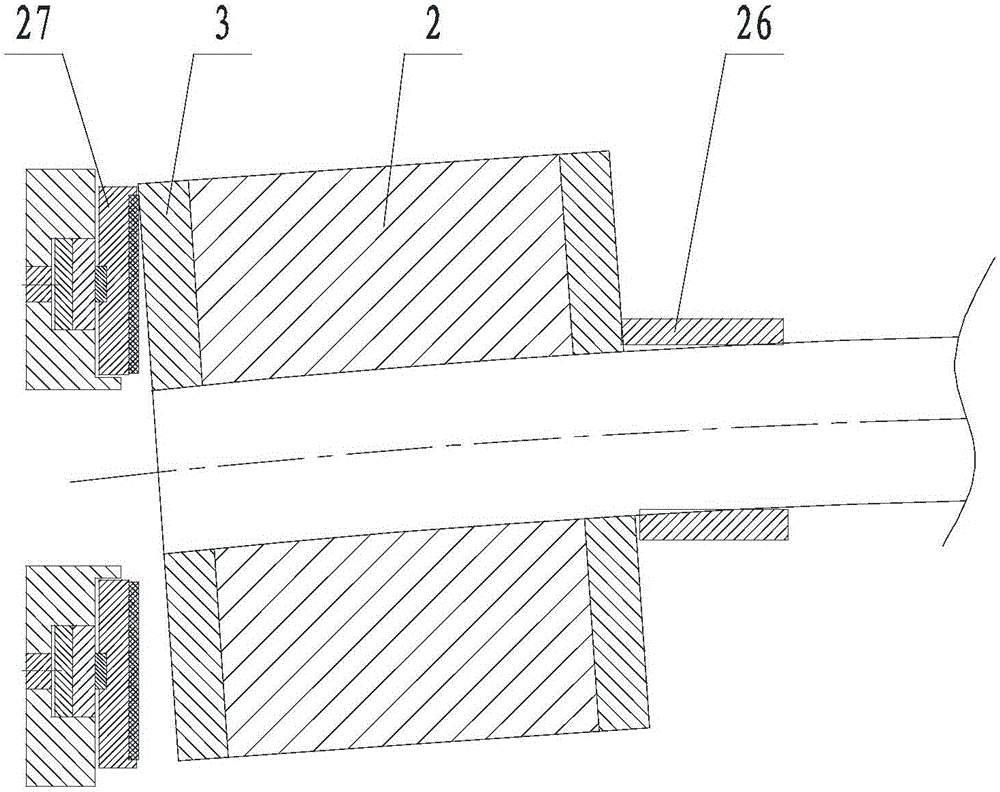

[0048] The present invention is located in the space surrounded by the outer cylinder body 1 and the end cover 6, the shaft 4 penetrates into the outer cylinder body 1, and the flywheel 2 is thermally installed on the position where the shaft 4 is located in the outer cylinder body 1, and the two parts of the flywheel 2 The lateral symmetry is provided with the thrust discs 3 which are respectively shrink-fitted on the shafts 4 .

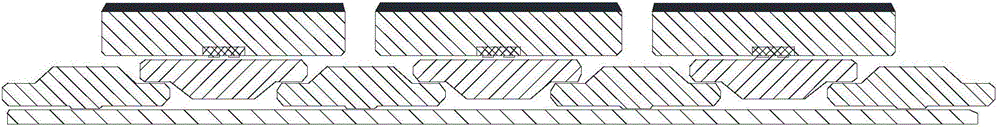

[0049] see Figure 4 , Figure 5 and Figure 20 The core package thrust bearing comprises an upper thrust bearing 10 symmetrically arranged on both sides of the flywheel 2, a lower thrust bearing 13 and a core package containing the flywheel 2, the upper thrust bearing 10, and the lower thrust bearing 13, wherein the core package includes a core Package connecting sleeve 9 , upper core package base 8 and lower core package base 12 . The upper core package base 8 and the lower core package base 12 are symmetrically arranged on both sides of the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com