Rapid cooling method and rapid cooling machine for bottled/canned liquid

A fast cooling and fast cooling machine technology, applied in the field of fast cooling equipment, bottled/canned liquid cooling, can solve problems such as leakage or rust of metal parts, uneven temperature of cooling liquid, and inability to reduce the temperature rapidly. The effect of equipment cost, small cooling capacity and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

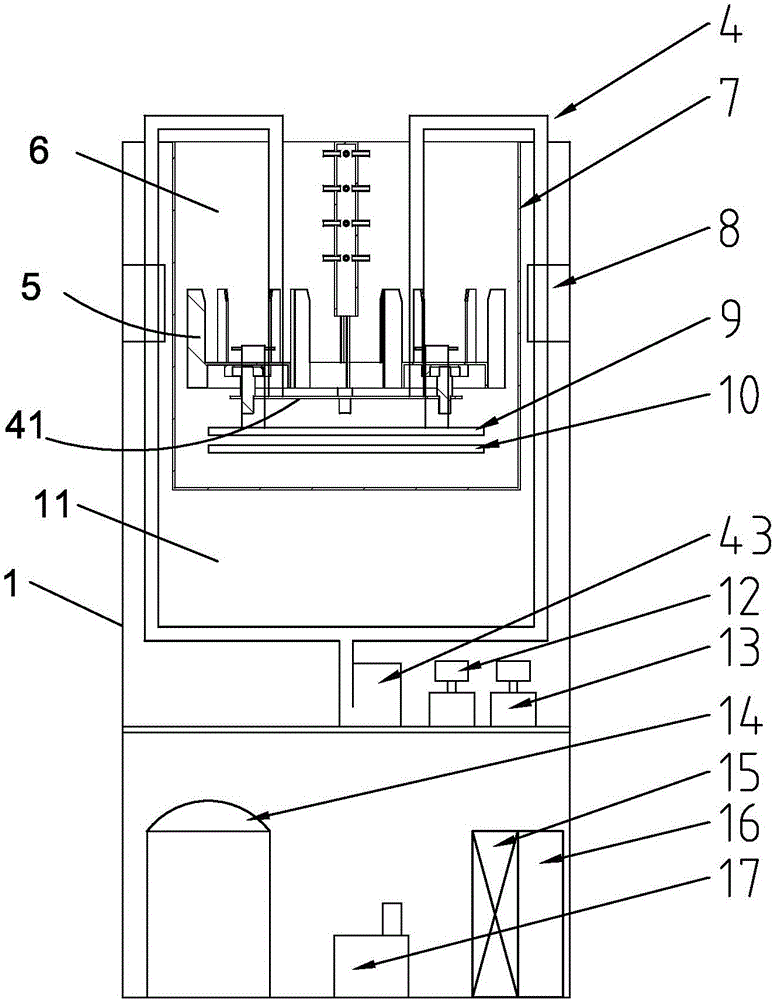

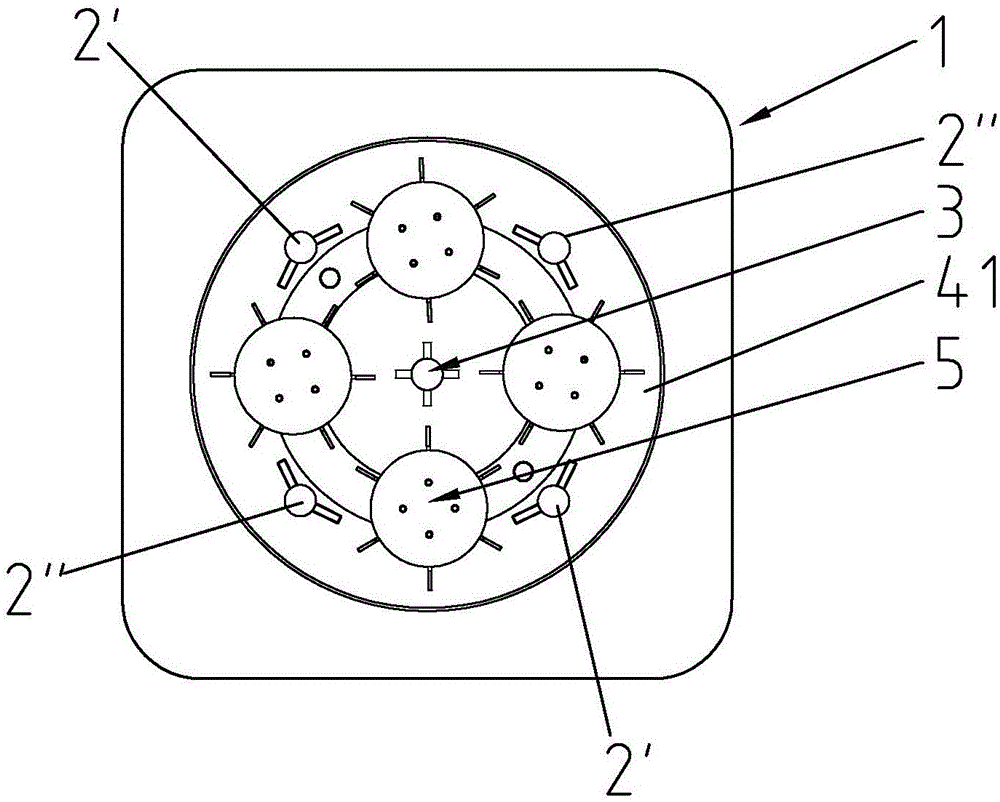

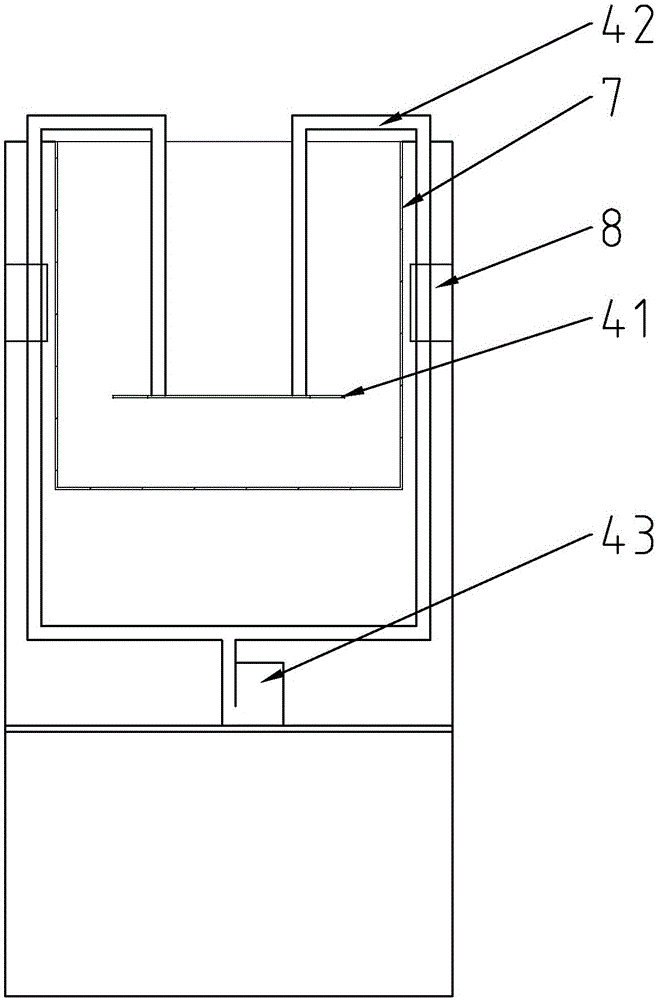

[0041] The rapid cooling method of bottled / canned liquid of the present invention is to make the bottle / can filled with the liquid contact with the low-temperature cooling liquid in a rotating state to exchange heat, and the liquid in the bottle / can is rapidly cooled to improve heat exchange. Efficiency and shorten the cooling time. The present invention uses low-temperature cooling liquid to spray on the outer surface of the bottle / can filled with liquid. The bottle / can has an axis that can rotate freely 360°, and the temperature of the low-temperature cooling liquid is minus 18° To 30° above zero, during the spraying process, ensure that the cryogenic cooling liquid provides at least one force along the tangential direction of the bottle / can, which enables the bottle / can to move around its axis under the impact of the liquid Line rotation. Through spraying, the low-temperature coolant forms a liquid film covering the surface of the bottle / can, which not only completes the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com