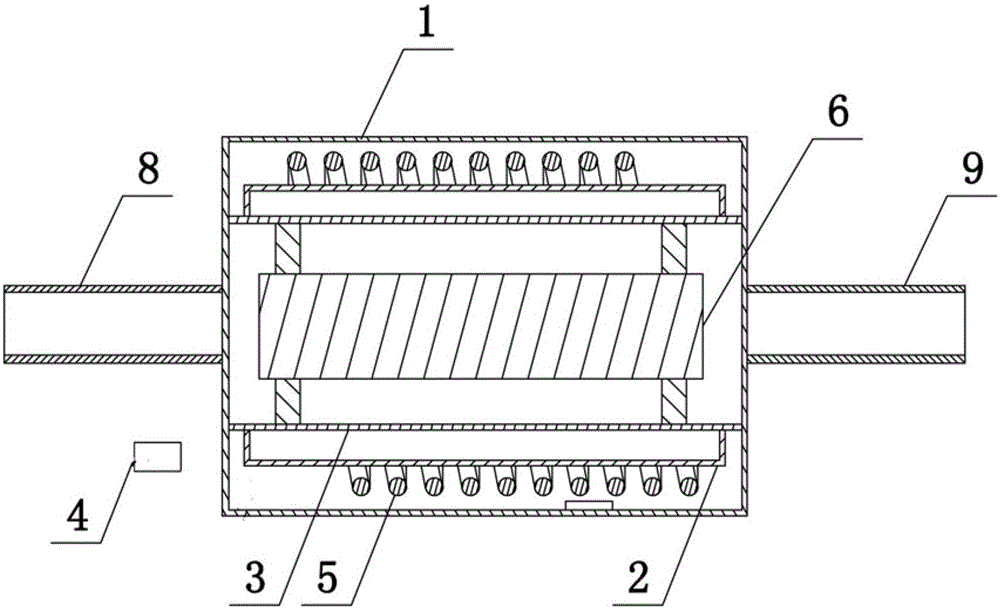

Electromagnetic induction heating device

An electromagnetic induction heating and heating body technology, applied in induction heating, induction heating control, coil devices, etc., can solve problems such as insulation performance degradation, electromagnetic coil aging, safety hazards, etc., achieve uniform heating temperature, increase temperature difference, and improve safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

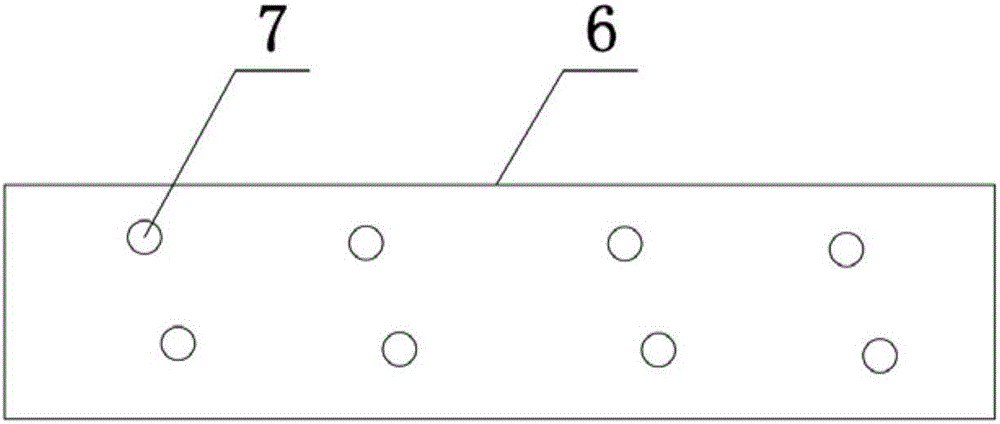

Method used

Image

Examples

Embodiment 2

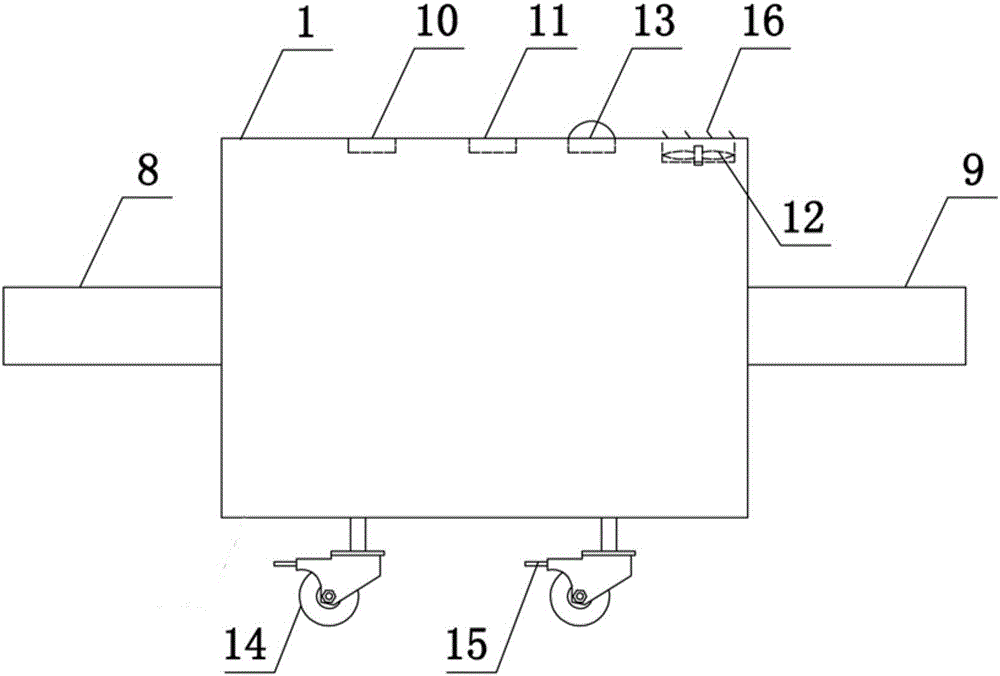

[0024] Such as image 3 with Figure 4 As shown, the universal wheel 14 is installed at the lower end of the insulation layer 1, and the brake 15 is installed on the universal wheel 14. The temperature sensing module 10, the control module 11, the cooling module 12 and the alarm module 13 are arranged on the inner wall of the insulation layer 1, and the output of the temperature sensing module 10 end is electrically connected to the input end of the control module 11, and the output end of the control module 11 is electrically connected to the drive module 4, the cooling module 12 and the alarm module 13 respectively, and the cooling module 12 is a fan, and the fan is fixed on the inner wall of the insulation layer 1, and the insulation layer 1 An air outlet 16 is provided at the corresponding position, and the alarm module 13 is an audible and visual alarm, and one end of the audible and visual alarm is located outside the casing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com