Heat dissipation device and electronic equipment

A technology of electronic equipment and heat dissipation device, applied in the field of electronic equipment, can solve the problems of slow system running speed, crash, surface temperature exceeding comfortable temperature, etc., to avoid system performance and improve heat dissipation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

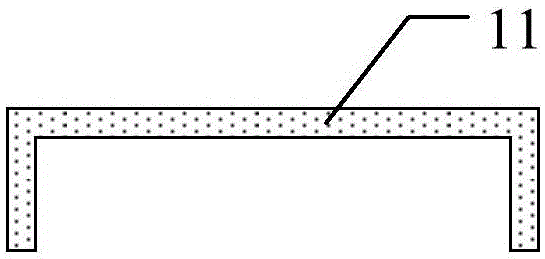

[0019] refer to figure 1 , which shows a schematic structural view of an embodiment of a heat dissipation device of the present invention, the heat dissipation device may specifically include: a metal heat dissipation cover 11; wherein, the metal heat dissipation cover 11 is a hollow airtight structure, and the metal heat dissipation cover 11 The interior is sealed with volatile liquid.

[0020] In practical application, since the metal heat dissipation cover 11 of the present invention can be a hollow airtight structure, and a volatile liquid is sealed inside the metal heat dissipation cover. The metal cooling cover can be covered or covered on the heat-generating parts of the electronic equipment, wherein the heat-generating parts can be any parts that can generate heat, such as CPU (Central Processing Unit, central processing unit) in the electronic equipment, power management unit ( Power Management Unit, PMU), etc. Therefore, when the metal heat dissipation cover 11 is ...

Embodiment 2

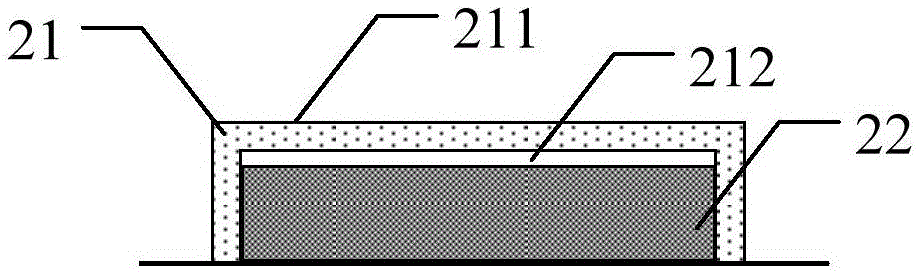

[0031] refer to figure 2 , which shows a schematic structural diagram of an embodiment of an electronic device according to the present invention. The electronic device may specifically include: the aforementioned heat dissipation device 21 and a heat generating component 22; the heat dissipation device 21 includes a metal heat dissipation cover 211, and the metal heat dissipation cover 211 is a hollow airtight structure, and its interior is sealed with a volatile liquid; wherein, the metal heat dissipation cover 211 in the heat dissipation device covers the heating component 22, and the metal heat dissipation cover 211 and the heating component 22 are welded on the PCB board superior.

[0032] In the embodiment of the present invention, the heat-generating components may specifically include components that easily generate heat in electronic equipment such as a CPU and a power management unit. Of course, in a specific application, the heat-generating component may be any co...

Embodiment 3

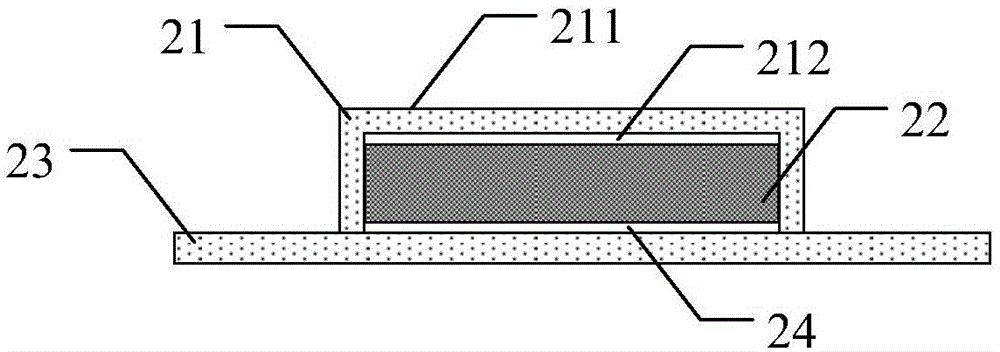

[0038] In yet another preferred embodiment of the present invention, the electronic device may further include a metal middle frame 23 on the basis of the structure shown in Embodiment 2;

[0039] Wherein, the heating component 22 is fixed on the metal middle frame 23 .

[0040] In practical applications, heat-generating components such as CPU and / or power management unit can be directly fixed on the metal middle frame 23 . refer to image 3 , which shows a schematic structural diagram of an electronic device including the heat sink 21 and the metal middle frame 23 of the present invention; alternatively, the CPU and / or power management unit can be fixed on the main board, and then the main board can be fixed on the metal middle frame 23 on. For the side of the metal middle frame 23 that is close to the CPU and / or the power management unit, the metal middle frame 23 can act as a radio frequency shield for the CPU and / or the power management unit; and for the other side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com