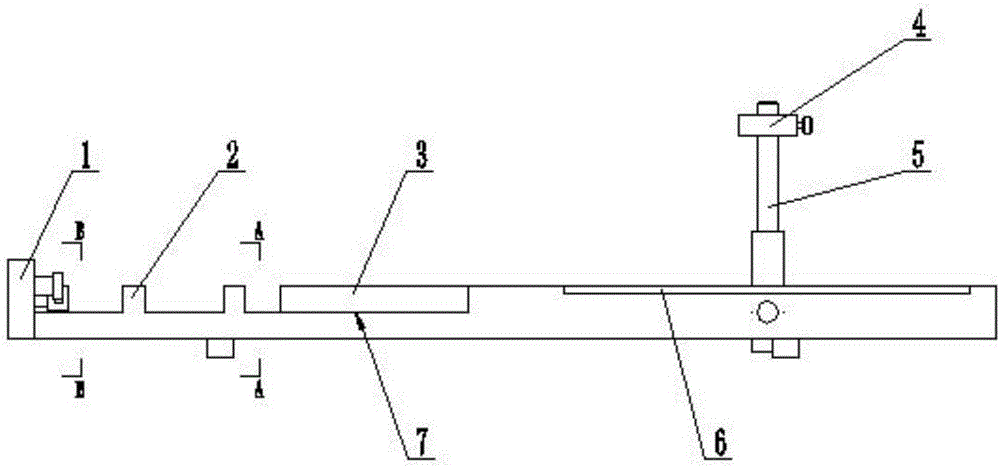

Zero position calibrating device for steel tape

A verification device, a steel tape measure technology, applied in the direction of a bendable ruler, etc., can solve problems such as use errors, and achieve the effects of avoiding verification errors, improving accuracy, and facilitating storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with the examples, the present invention is further described, the following examples are illustrative, not limiting, and the protection scope of the present invention cannot be limited by the following examples.

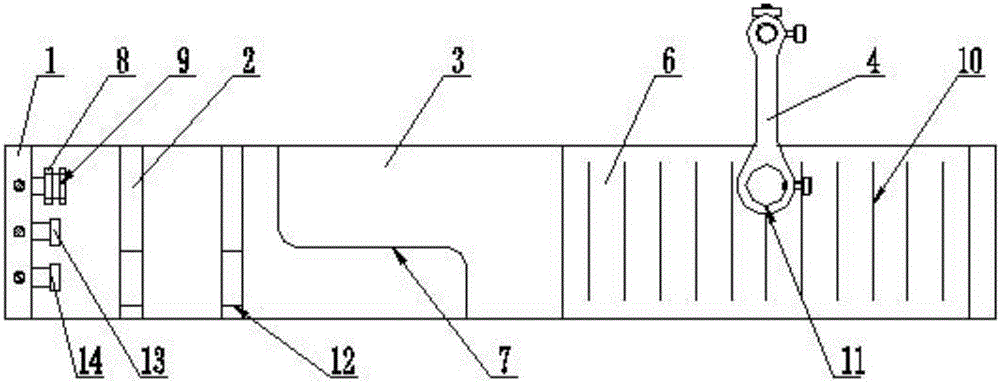

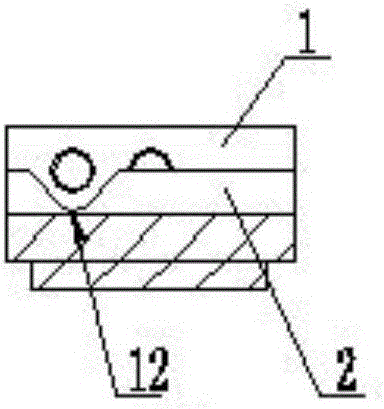

[0027] A steel tape zero position verification device, the present invention is characterized in that it includes a base plate 3, a limit plate 1 perpendicular to the base plate is vertically installed on one side of the upper end surface of the base plate, and the limit plate is located on the In the end face of the inner side of the base plate, there are respectively spaced and paralleled installations of the inner size limit block 8 of the ruler hook, the outer size limit block 13 of the ruler hook and the limit block 14 of the sounding ruler head, which are respectively used for the ruler hook and the depth measurement of the steel tape. The head of the ruler is limited, and the steel tape and the sounding ruler are in the limit state,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com