Calibration methods for pressurized tools

A calibration method and tool technology, applied in the field of calibration, can solve the problems that the range of tension of parts cannot be directly displayed, the requirement of loading accuracy cannot be guaranteed, and the diameter of the pressure gauge dial is small, so as to facilitate accurate observation and reading, ensure the requirements of loading accuracy, Easy-to-observe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

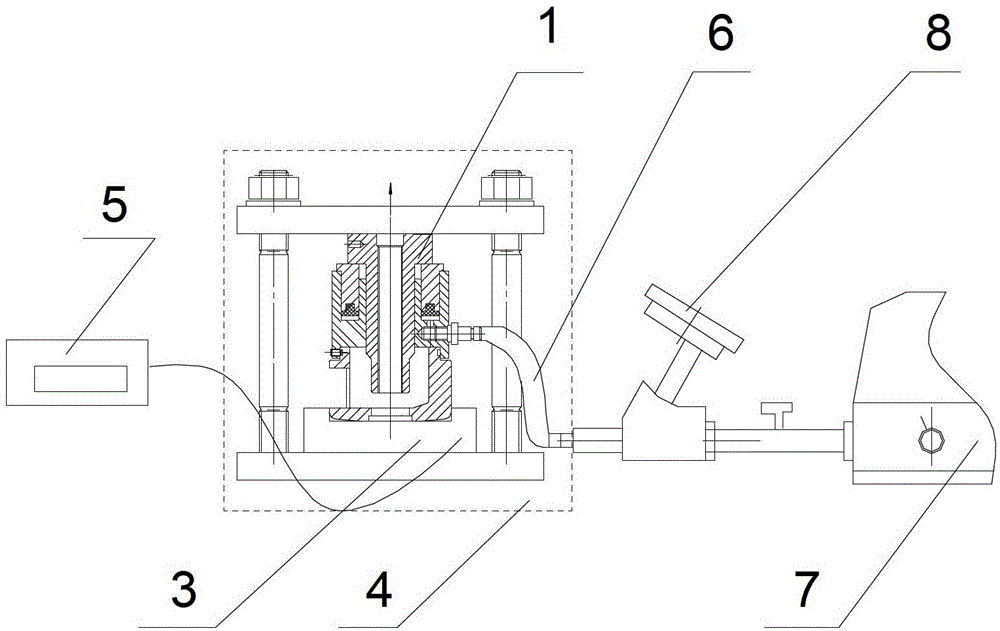

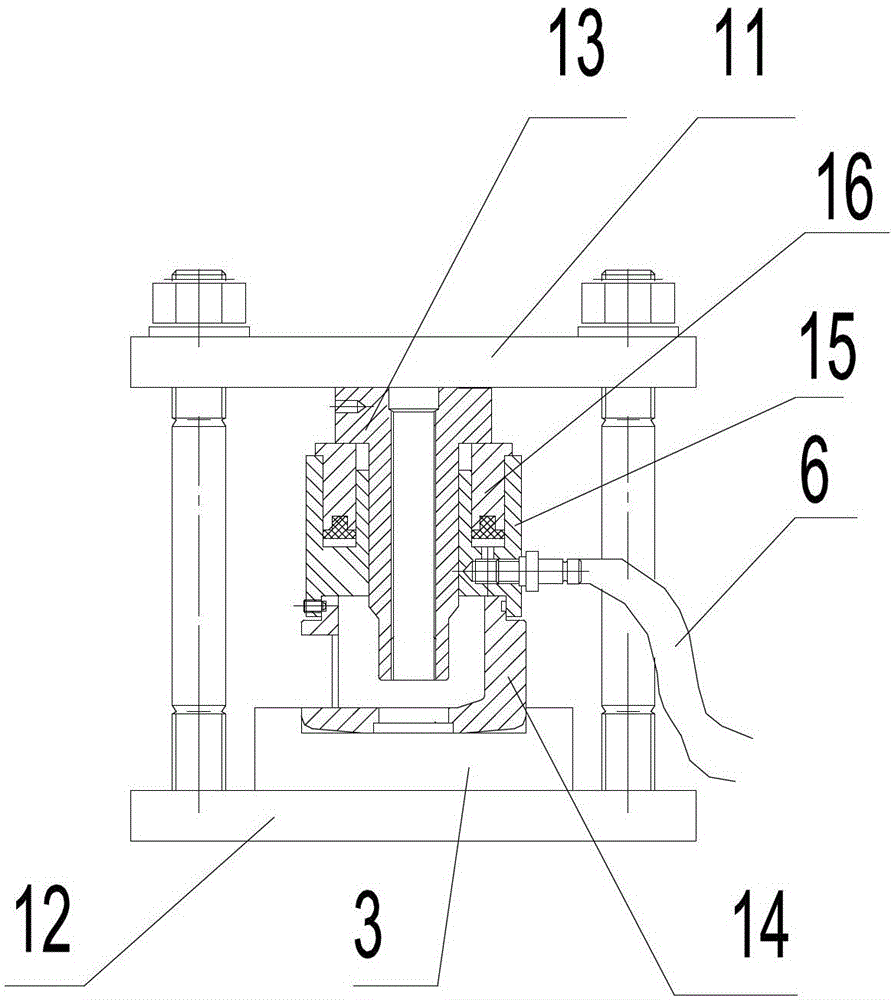

[0019] As shown in the figure, the calibration method of the pressurized tool includes the following steps:

[0020] 1) Design and process the fixture, the fixture is rigid, and can install the stretching body 1, and can transmit the tension of the stretching body 1 to the sensor 3;

[0021] 2) Fixture installation: assemble the parts of the finished fixture 4, and install the sensor 3 on the fixture 4 at the position where the tension body 1 transmits the tension, and the sensor 3 is connected to the reading device 5;

[0022] 3) Install the pressurization tool: connect the high-pressure pump 7 to the stretching body 1 through the high-pressure hose 6, and set a pressure gauge 8 at the oil outlet of the high-pressure pump 7;

[0023] 4) Loading: load the clamp 4 with the pressurizing tool, when the reading device 5 shows the minimum value that the part needs to be loaded, record the reading of the pressure gauge 8, and the pressurizing tool releases the pressure, so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com