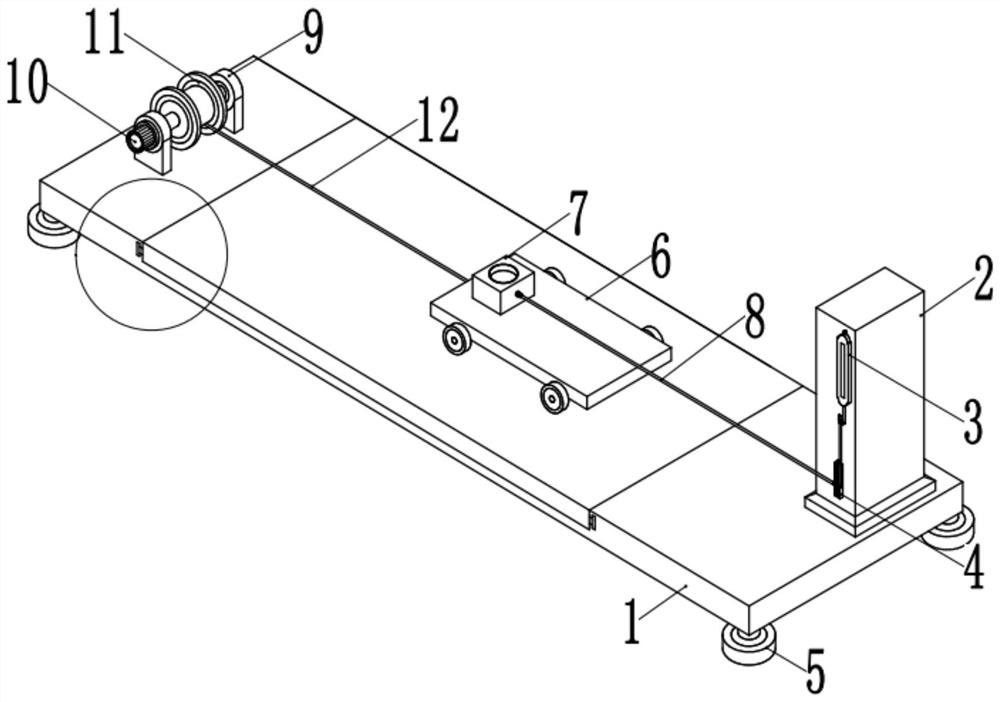

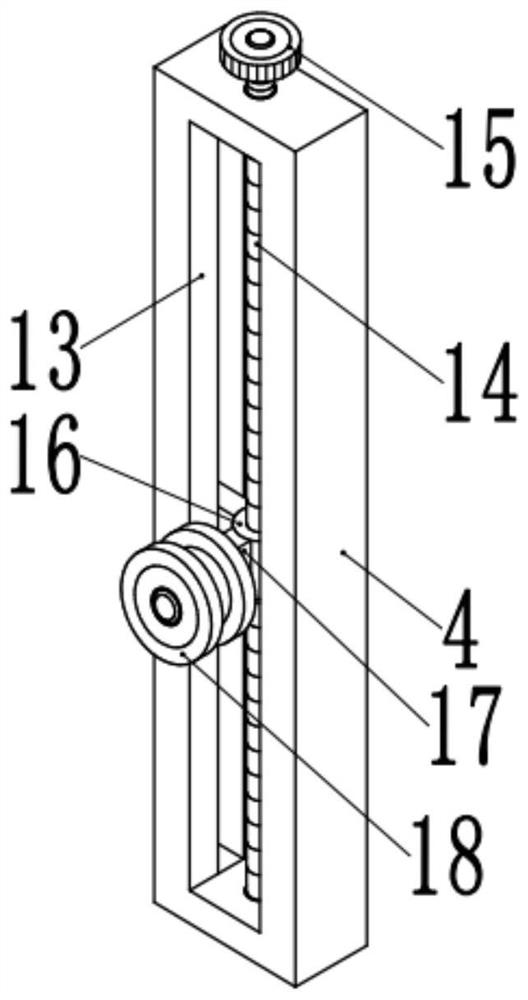

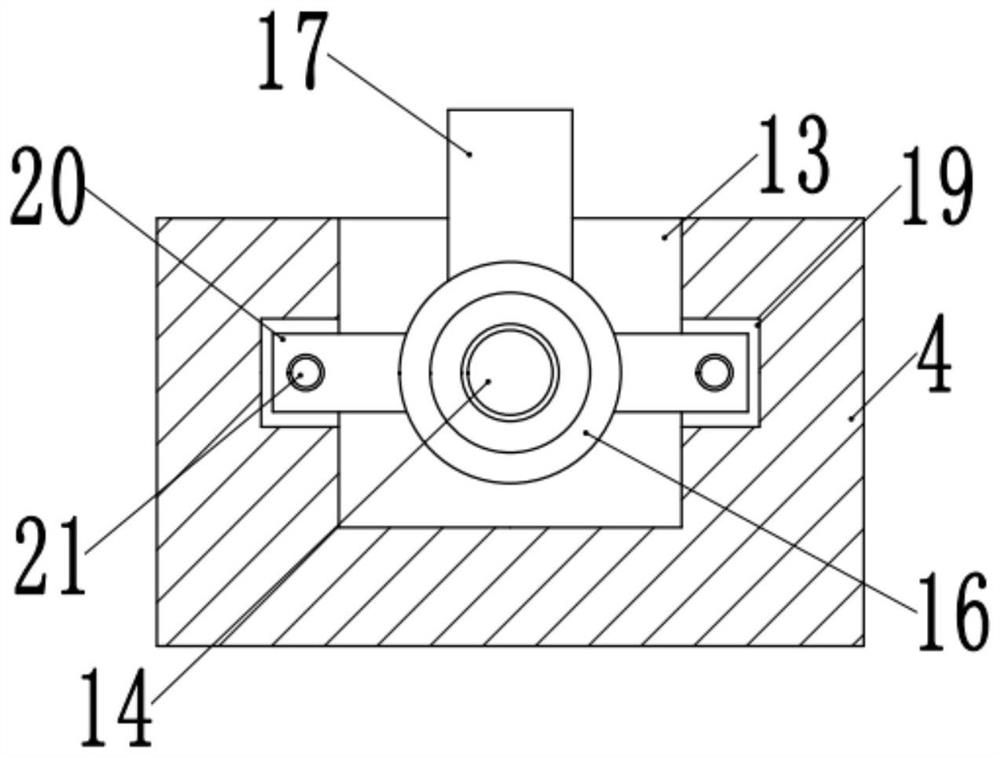

Experimental device for friction force research and use method thereof

An experimental device and friction technology, applied in the experimental field of friction research, can solve the problems of poor demonstration effect, inability to roll friction demonstration, large workload, etc., to achieve convenient operation, convenient observation and reading, and improved stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Example 1: The relationship between the magnitude of sliding friction and the roughness of the contact surface

[0055] Under the condition that the pressure on the contact surface remains unchanged, use a different test plate 24 with a towel surface, cotton cloth surface or other materials such as rubber surface, iron surface, etc. to explore the relationship between the sliding friction force and the roughness of the contact surface. relation.

Embodiment 2

[0056] Example 2: The relationship between the magnitude of the sliding friction and the pressure on the contact surface

[0057] Under the condition that the surface of the test bench 1 remains unchanged, weights of different masses are added to the column block 7 to change the pressure on the contact surface, so as to explore the relationship between the sliding friction force and the pressure on the contact surface.

Embodiment 3

[0058] Example 3: The relationship between the magnitude of the sliding friction force and the relative motion speed

[0059] Under the condition that the pressure on the contact surface and the roughness of the contact surface remain unchanged, the speed of the motor 10 can be changed by selecting the play button and the fast-forward button, or the output voltage of the transformer can be adjusted to change the relationship between the flatbed trolley 6 and the column block 7. The speed of movement allows it to conduct several experiments at different speeds to explore the relationship between the magnitude of the sliding friction and the relative movement speed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com