A visual displacement measurement system and its measurement method

A technology of displacement measurement and measurement method, which is applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of only suitable for industrial production environment, high price, different measurement points, etc., and achieve a wide range of measurement applications, high accuracy, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

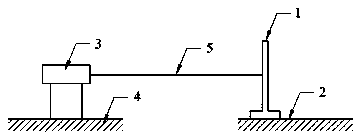

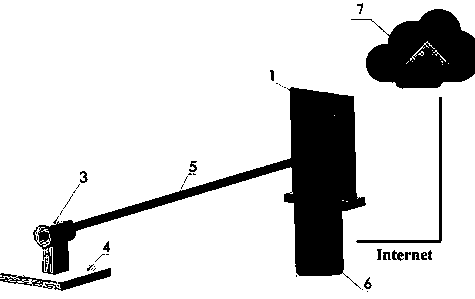

[0034] The technical scheme of the present invention is specifically set forth below in conjunction with embodiment, as figure 1 As shown, the present invention discloses a visual displacement measurement system, including a reference plate 1 for positioning the measured object 2, a laser 3 arranged on a remote reference 4, and used for collecting information on the reference plate 1 A movable acquisition device (not shown in the figure); the laser beam 5 emitted by the laser 3 is placed in the reference plate; the movable acquisition device includes an image acquisition lens.

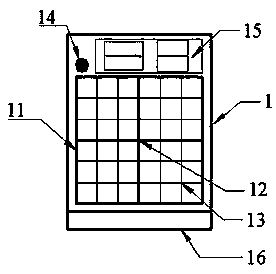

[0035] Wherein, the material of the reference plate 1 is not limited, and the size is not limited, as long as the graphics can be displayed clearly and accurately. to combine figure 2 As shown, the surface of the reference plate is provided with a measurement reference frame 11, a coordinate direction punctuation point 14, and an information code 15; as long as the acquisition equipment can recognize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com