A kind of stripping device and stripping method

A technology for stripping and adjusting the device, applied in the directions of light guide, optics, instruments, etc., can solve the problems of easily damaged optical fiber, optical fiber burnout, uneven size of the incision, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

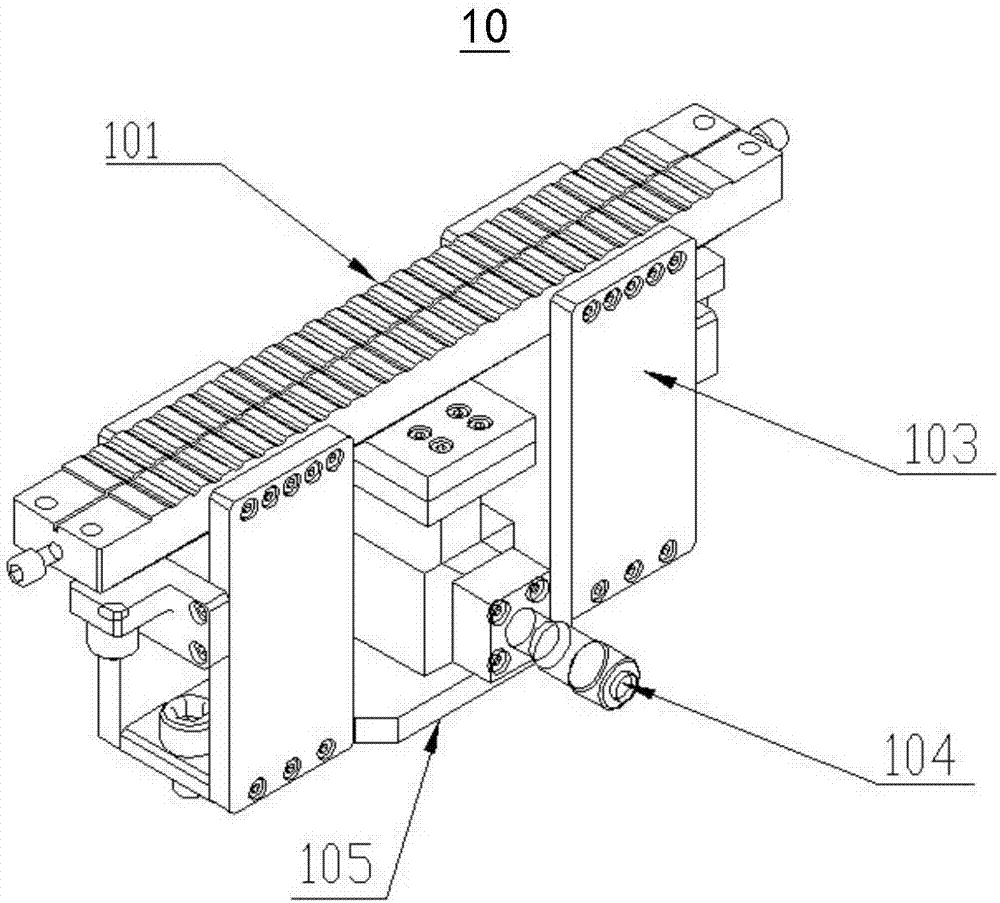

[0032] refer to figure 2 , the film stripper 10 includes: an optical fiber placement device 101, a stripping depth adjustment block (not shown), a fixed bracket 103, a displacement platform 104, and a base 105, wherein the fixed bracket 103 connects the optical fiber placement device 101 to the base 105 through the fixing device Connection, the stripping depth adjustment block and the displacement platform 104 are fixedly connected to form a supporting platform together to support, and are arranged in the inner space formed by the optical fiber placement device 101, the base 105 and the fixing device 103, the top surface of the base 105 and the displacement platform 104 is in contact with the bottom, and at the same time, the stripping depth adjustment block cooperates with the optical fiber placement device 101.

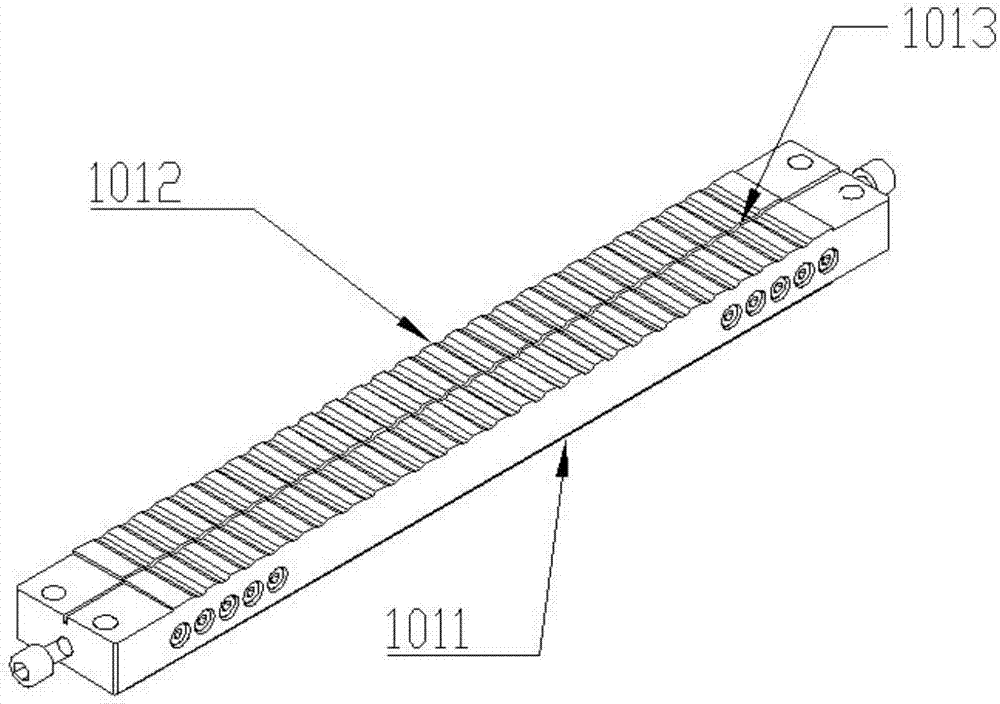

[0033] refer to image 3 , the optical fiber placement device 101 is in the shape of a cuboid as a whole and includes a base 1011 , at least one groove 1012 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com